Articles

-

-

Key Principles of DfAM for Binder Jet

DfAM for binder jetting refers to the design principles and best practices tailored to reap the benefits of this additive manufacturing technology.

-

5 Studies on the Best 3D Printer for University Research

The most-researched binder jetting platform in the world, known for easy operation and open architecture that make it perfect for university research projects.

-

Enhance Educational Offerings and Research Capabilities with Binder Jetting

Future innovators and mad scientists in-the-making need the most disruptive tools – and the world of 3D printing offers plenty of processes way more thrilling than what most students picture when they hear the word “manufacturing.”

-

-

-

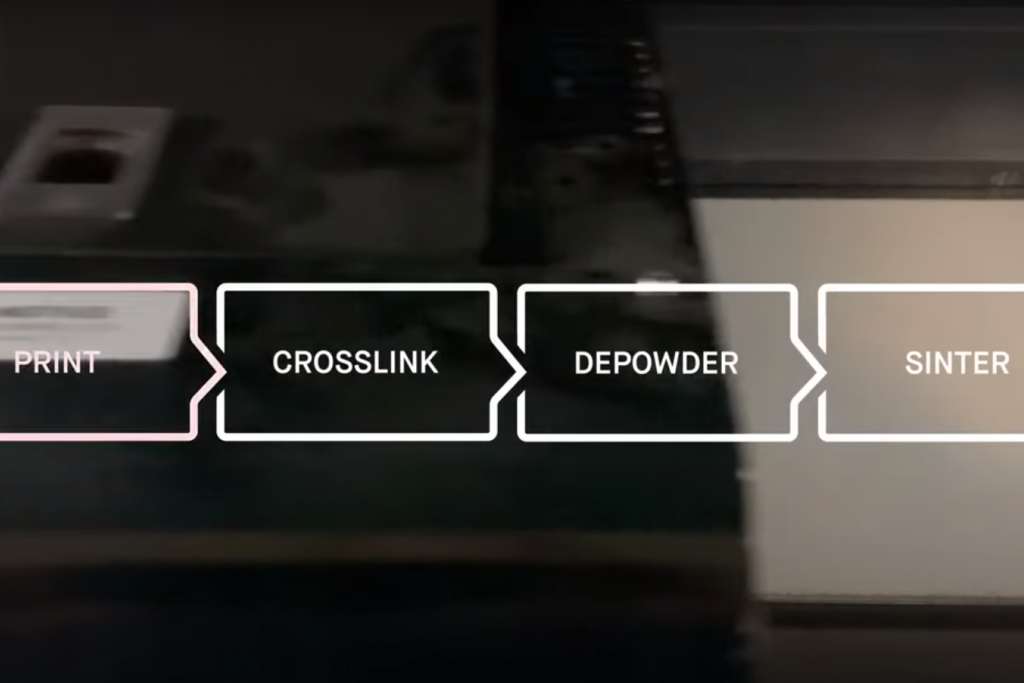

Introduction to the Binder Jetting Process

One of ASTM's seven recognized additive manufacturing technologies, binder jetting 3D prints powders, including metal, technical ceramics, and sands, into complex shapes at unmatched speeds. Watch our Binder jet video series to learn more.

-

How do you value a multi-purpose tool like metal binder jet 3D printing?

Much of the return on investment (ROI) of binder jetting lies in the complex intangibles and specific applications, or where one operates in the supply chain

-

Embracing the Future: 3D Printing Revolutionizes Manufacturing and Attracts a New Generation of Workers

Technologies like 3D printing can help manufacturers bridge the generational gap, making them stand out to attract a top workforce while also ensuring the future of their business

-

-

-

Desktop Metal's Additive Experts Offer Engineering Partnerships to Solve Customer Challenges

When an innovative automotive company wanted to explore what additive manufacturing could do for a specific application, they turned to Desktop Metal’s team of 3D-printing experts

-

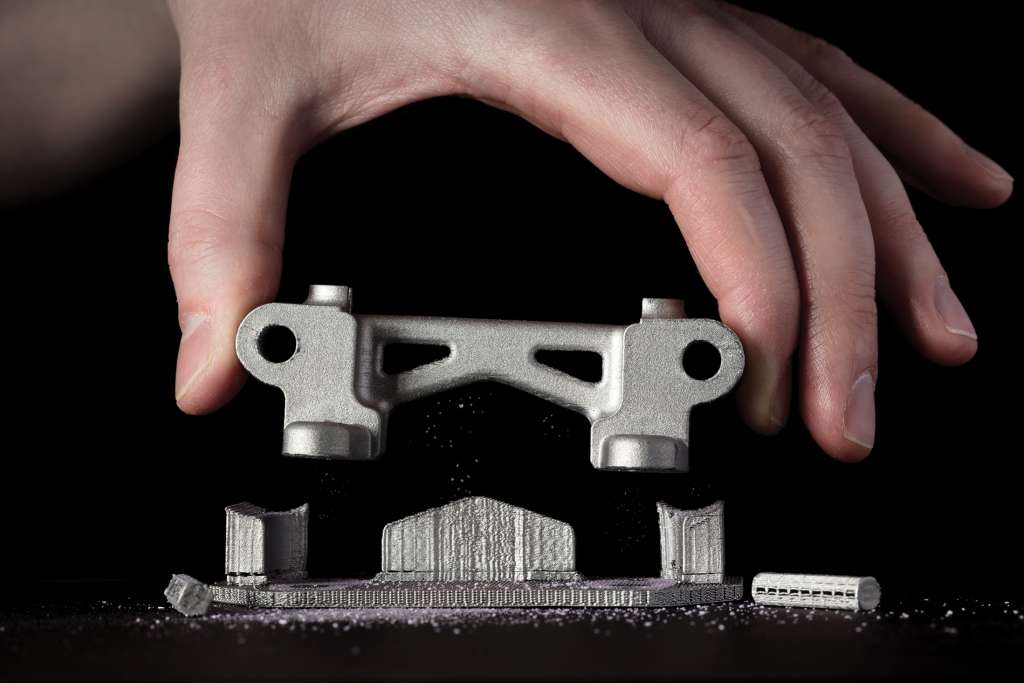

Metal 3D Printing Production Stories: The Shop System Delivers Binder Jetting Success

Learn how Shop System customers around the globe are transforming their operations with advanced, digital manufacturing.

-

Top 5 Reasons Every University Needs a Studio System Metal 3D Printer

Metal 3D printing is revolutionizing industries by enabling the creation of complex parts with intricate geometries that were once impossible to produce. Creating components by building up metal layer-by-layer has numerous applications and advantages, particularly for universities.

-

-

-

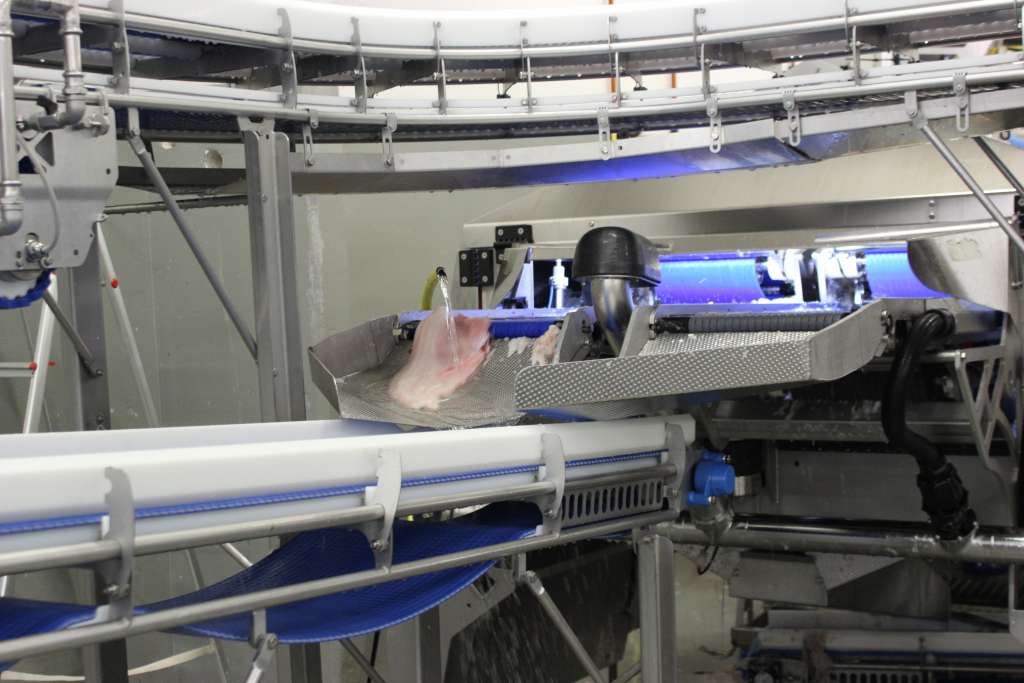

Food Processing

Fish processing equipment revolutionized with metal 3D printing

-

Top 5 Reasons Metal 3D Printing is Spicing Up Food & Beverage Equipment

While mentions of 3D printing for food may bring to mind chocolate extruded into cool decorative shapes, additive manufacturing is actually transforming the industry behind the scenes – making food and beverage processing equipment safer, more productive, and delivering all-new innovations

-

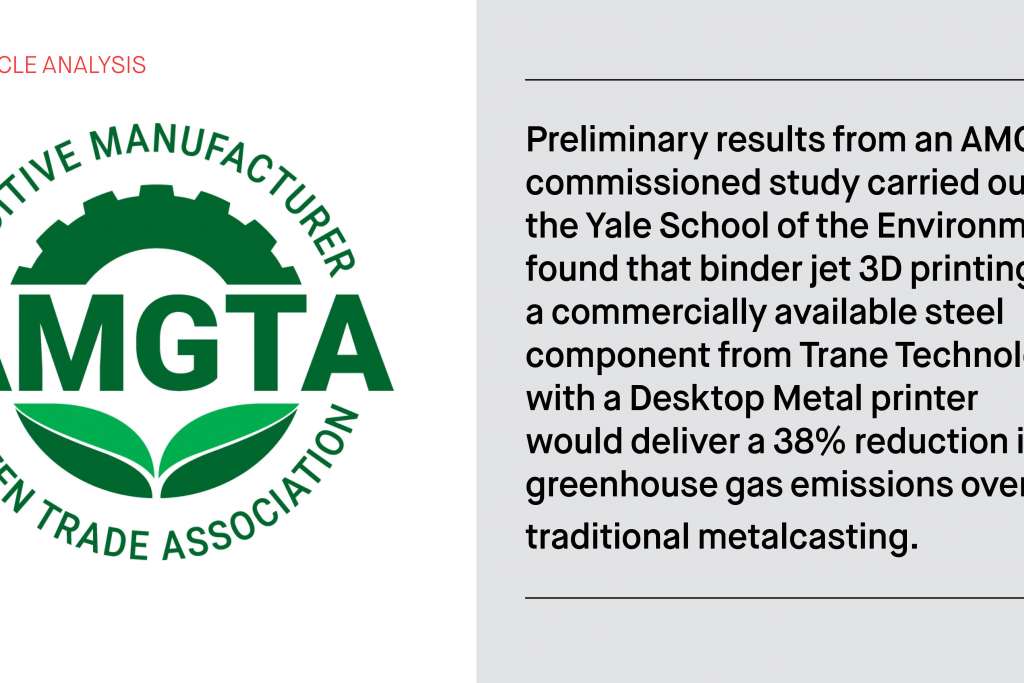

Preliminary Findings of the Yale-AMGTA Binder Jet Life Cycle Analysis: Binder Jet Delivers 38% Reduction in Greenhouse Gas Emissions

Preliminary Findings of the Yale-AMGTA Binder Jet Life Cycle Analysis: Binder Jet Delivers 38% Reduction in Greenhouse Gas Emissions

-

-

-

Binder Jet 3D Printing of Copper

Desktop Metal partners with global automotive manufacturer and leading material supplier to qualify Copper Alloy C18150

-

Metal 3D Printing for Design of Complex Mechanical Assemblies

Additive manufacturing dramatically simplifies the process of creating custom parts. Because it doesn’t rely on tooling or fixturing, 3D printing often allows users to print parts faster and at lower costs than machining.

-

Metal 3D printing for service bureaus & machine shops

Additive manufacturing allows service bureaus to extend the benefits of metal 3D printing - such as assembly consolidation, new levels of geometric freedom, and features like overhangs and internal channels - to their customers.

-