Articles

-

-

Metal 3D printing for manufacturing tooling

Tooling is a general term for components used in various manufacturing processes—including machining, injection molding, extrusion, stamping, casting, as well as workholding jigs, fixtures, and end of arm tooling.

-

Metal 3D printing for government and defense

Given the mission-critical nature of many government and defense applications, manufacturers face a host of challenges, from the need to move from low- to high-volume manufacturing, ensuring parts can stand up to often-harsh conditions, and efficiently producing replacement parts.

-

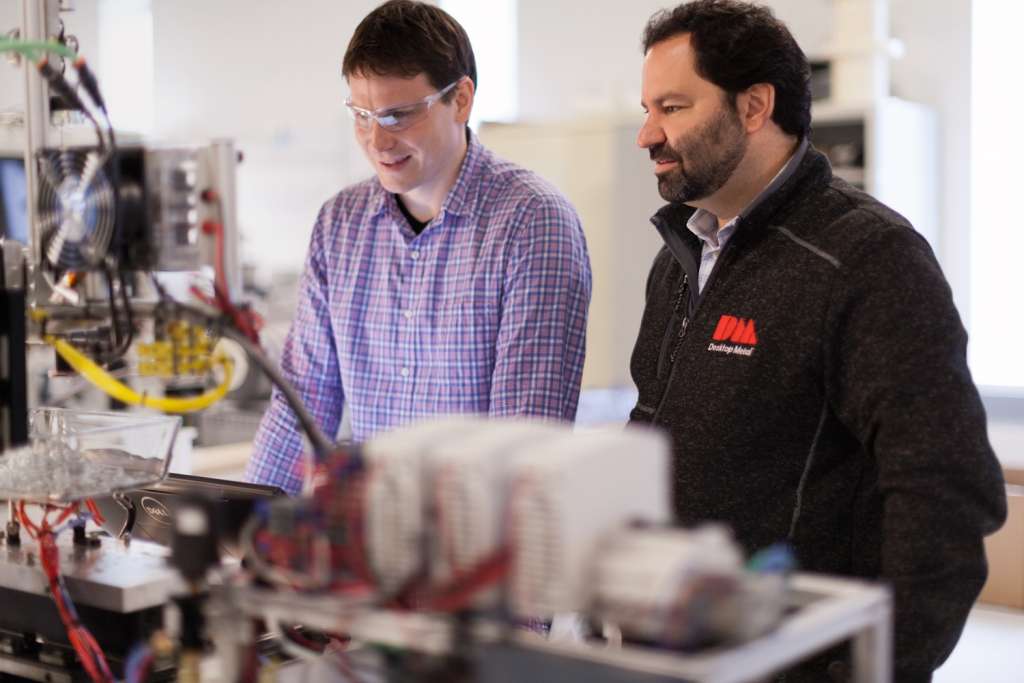

Introduction to the Studio System

This five-part video series explains the step-by-step process of the only office-friendly metal 3D printing system in the world.

-

-

-

3D printed flexures

3D printing offers the design flexibility required to produce high-quality metal flexures—enabling targeted flexibility for compliance in specific degrees of freedom.

-

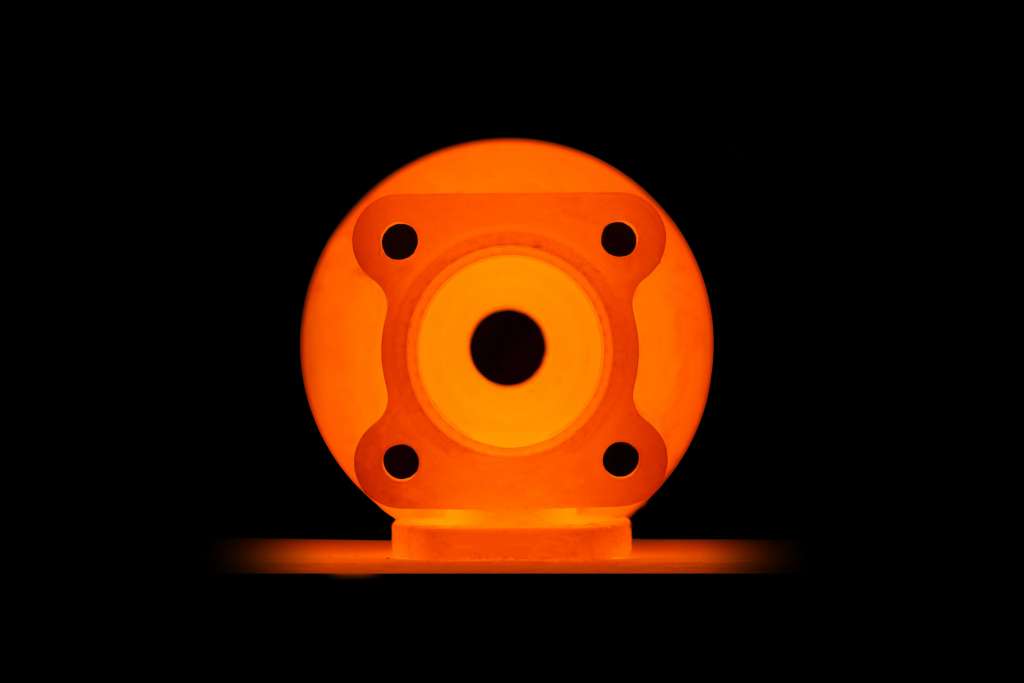

Thermal Debinding and Sintering 101

Sintering is the final step of all powder metallurgy processes, including the metal 3D printers at Desktop Metal.

-

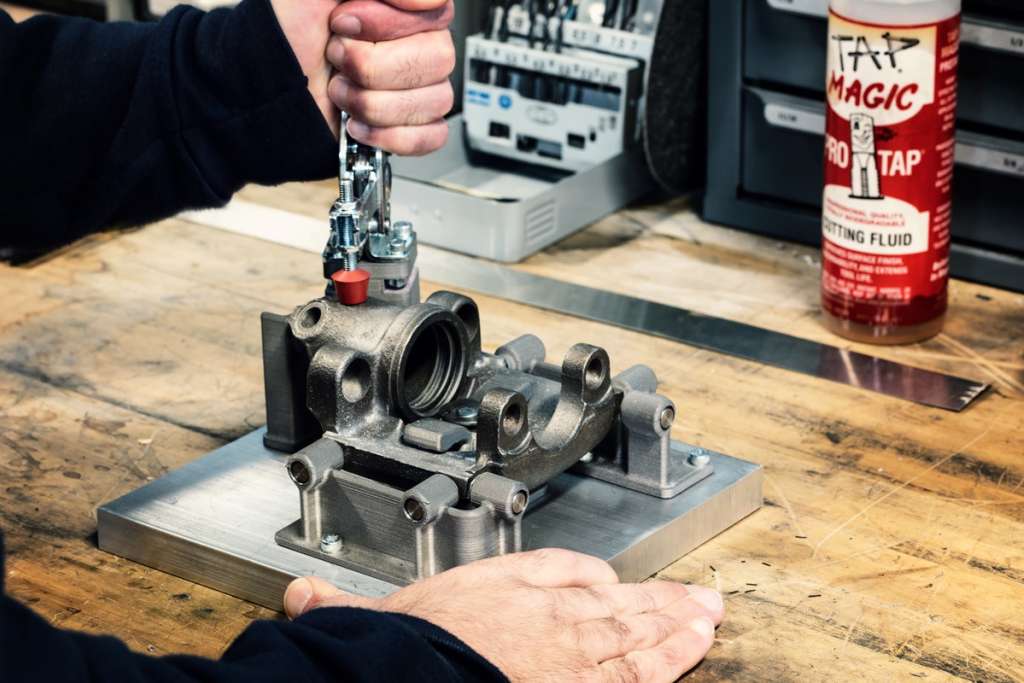

Metal 3D printing for jigs & fixtures

Essential to lean manufacturing, the production of custom jigs and fixtures is often deprioritized against a long list of manufacturing needs. In-house metal 3D printing enables the rapid production of a jig or fixture that is optimized for a specific need.

-

-

-

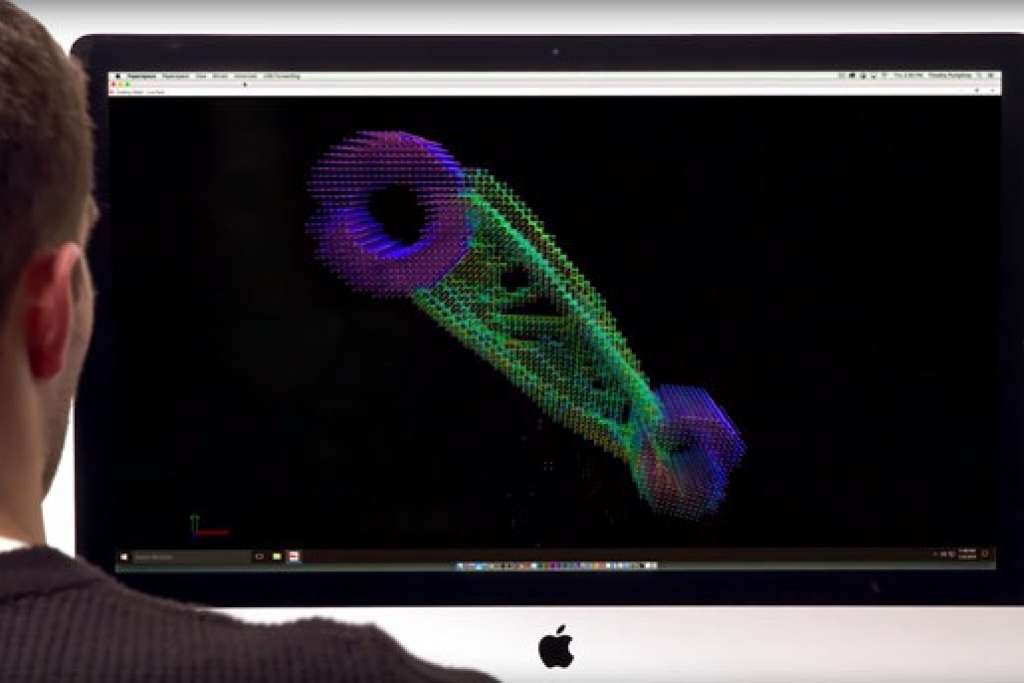

Live Parts™

Live Parts™ makes it easy to go from complex constraints and loading conditions to optimized, manufacturing-ready models in a matter of minutes.

-

The Importance of Inerting for Additive Manufacturing

One of the key considerations for any metal 3D printing system is the atmosphere inside the build chamber.

-

Metal 3D printing for tooling

The process of tool-making can be tedious due to high tolerance requirements, complex geometries, and materials that are difficult to machine. In-house metal 3D printing enables tool-makers to meet these challenges with greater efficiency.

-

-

-

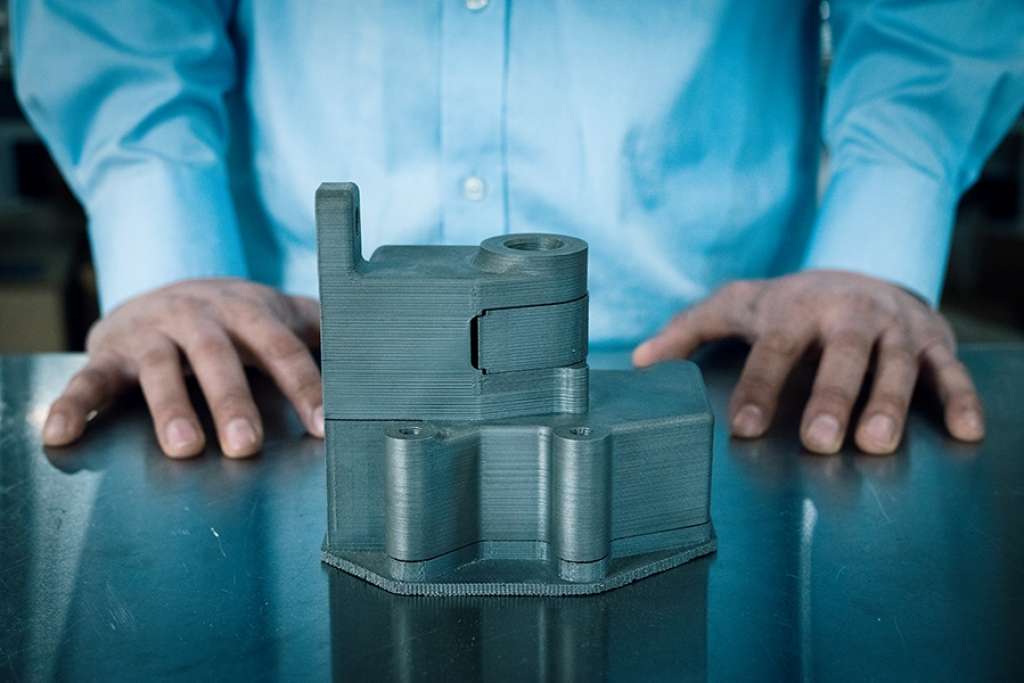

Key Applications for metal 3d printing on the Studio System

An overview of the Studio System for functional prototyping, jigs and fixtures, tooling, and low volume production.

-

These 4 simple solutions can help make the manufacturing industry more sustainable

The way we make things is changing. New manufacturing technologies like 3D printing offer benefits to both companies and consumers - but can also help usher in a cleaner, more sustainable world.

-

2019 year in review: looking back, and ahead

As 2019 drew to a close, Desktop Metal CEO Ric Fulop paused to both look back on the highlights of the year that was, and ahead, to the future of additive manufacturing in the coming decades.

-

-

-

Deep Dive: Bound Metal Deposition (BMD)

BMD leverages the most widely-used plastic 3D printing method (FFF) and the high-quality, well-studied alloys found in MIM

-

3D printed internal channels

A difficult-to-manufacture feature found in parts such as manifolds, heat exchangers and tooling—allowing for the passage of fluids through the body of a part

-

3D printed golf clubs

3D printing is changing the way that golf clubs are made, from design to manufacturing

-