Harness the power of binder jetting with manufacturing preparation software for the successful production of powder metal sintered parts

-

— 01

Sintering Simulation

-

— 02

Support Generation and Surface Offsetting

-

— 03

Scan-Based Adjustments

Rather than fight the effects of gravity, friction, shrinkage and distortion, Live Sinter software embraces nature and provides advanced simulation tools to predict and correct for errors when sintering 3D printed parts from Desktop Metal binder jetting systems. Rather than printing a part straight to have it warp out of spec, Live Sinter prints an oppositely warped part that will sinter to meet dimensional tolerances. Live Sinter enables unique distortion compensation to help manufacturers not only reduce costs, but enable sintering to be successfully applied to a wider range of applications.

Sintering Challenges

Though it is used in metal injection molding or pressed and sintered to fabricate millions of parts each year, sintering remains one of the main challenges to the broad adoption of metal binder jetting technology. Desktop Metal Live Sinter was designed by our advanced simulation software team to eliminate the trial and error required to achieve high-accuracy parts via powder metallurgy-based additive manufacturing processes.

Metal binder jet 3D prints fuse together during the sintering process to form a dense metal part. In the sintering furnace those parts shrink and experience significant forces that can lead to deformations. Many manufacturers struggle to obtain satisfactory results, often resorting to large sacrificial support structures in an attempt to prevent distortion, an approach that often fails to overcome the natural tendencies of parts to still warp and crack.

Desktop Metal Live Sinter was developed as a tool to for engineers to develop distorted geometries that can dramatically reduce or eliminate the cost of printing supports. Predictable sintering outcomes with Live Sinter significantly improve upon reliable dimensional accuracy and the delivery of higher part qualities.

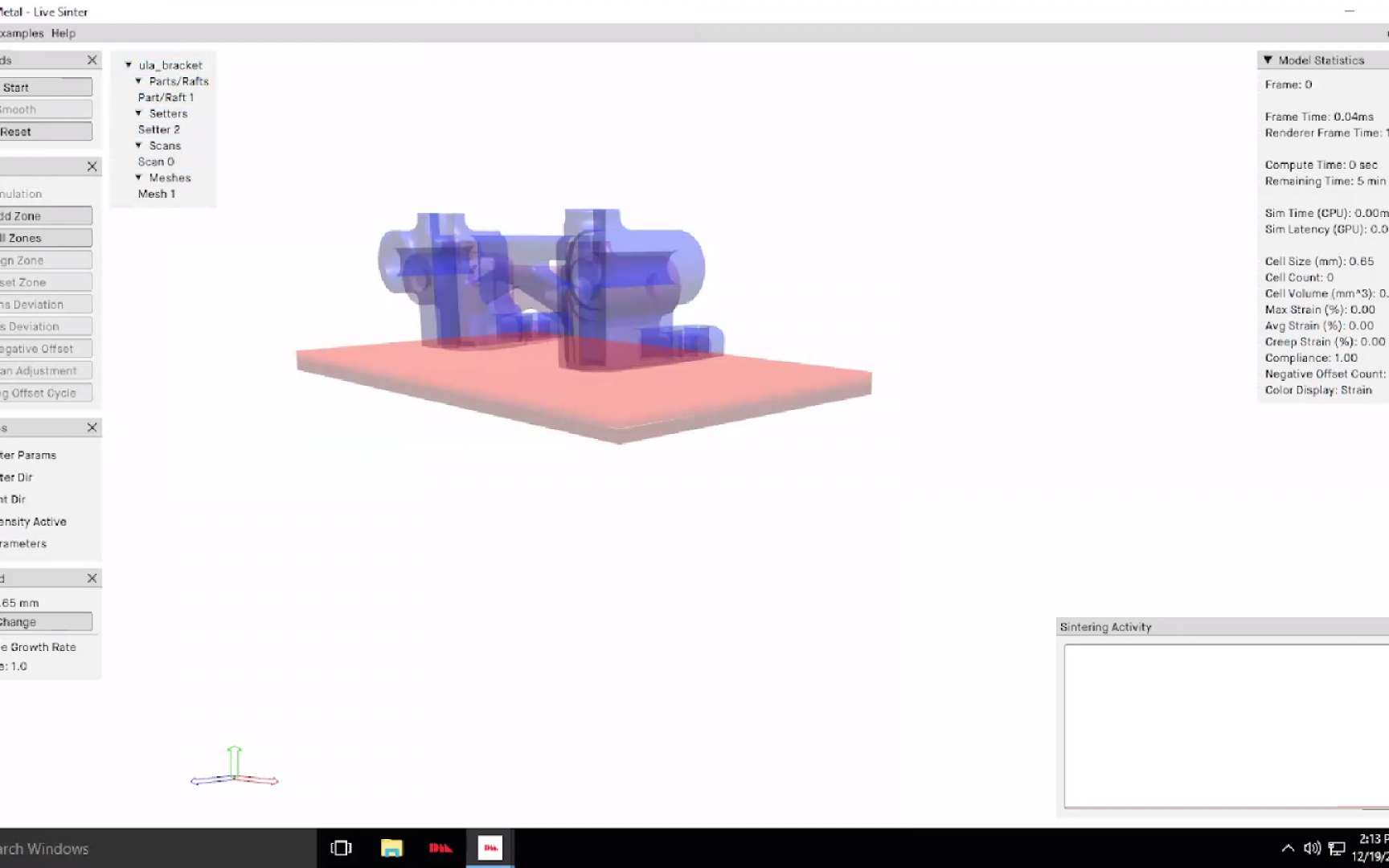

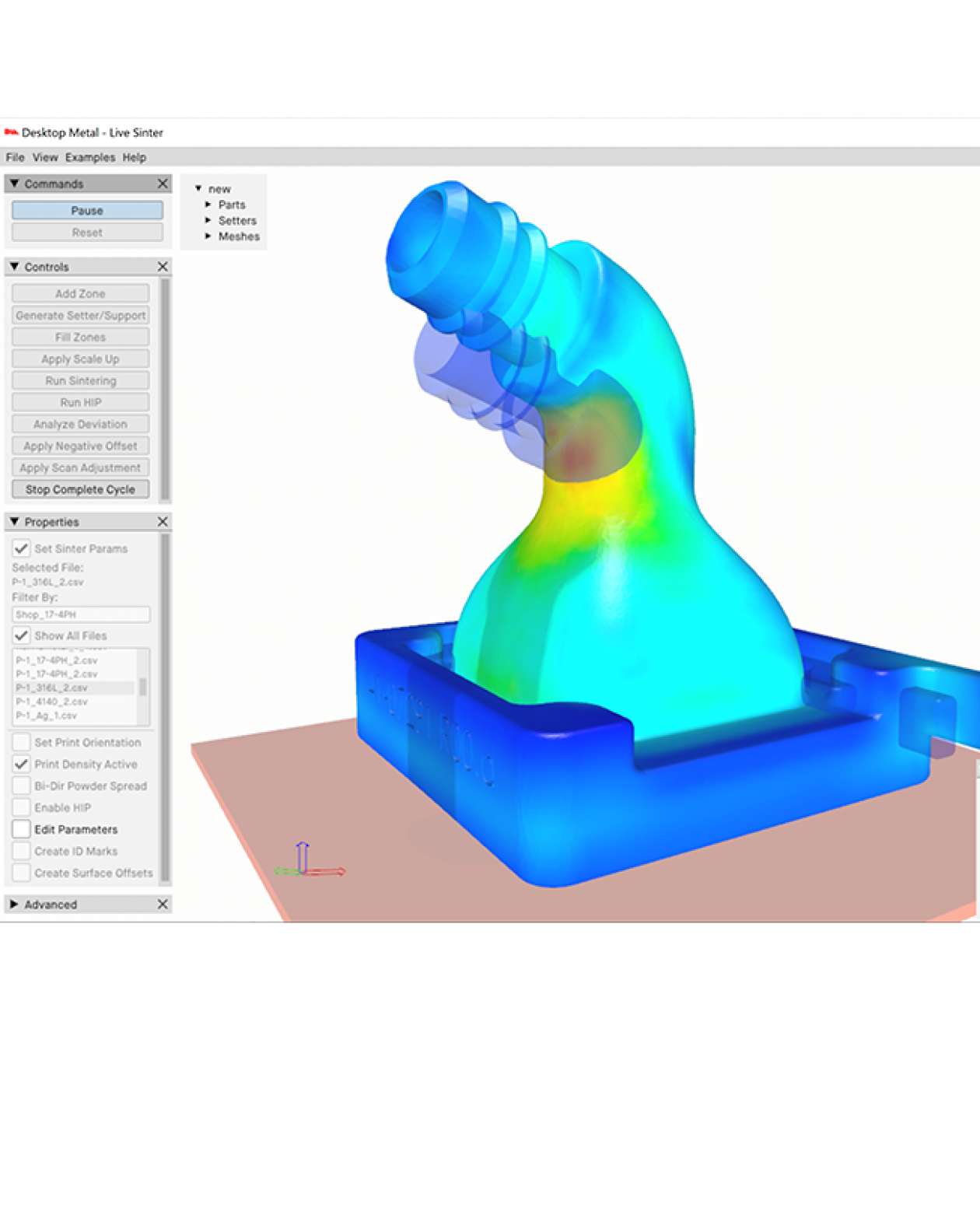

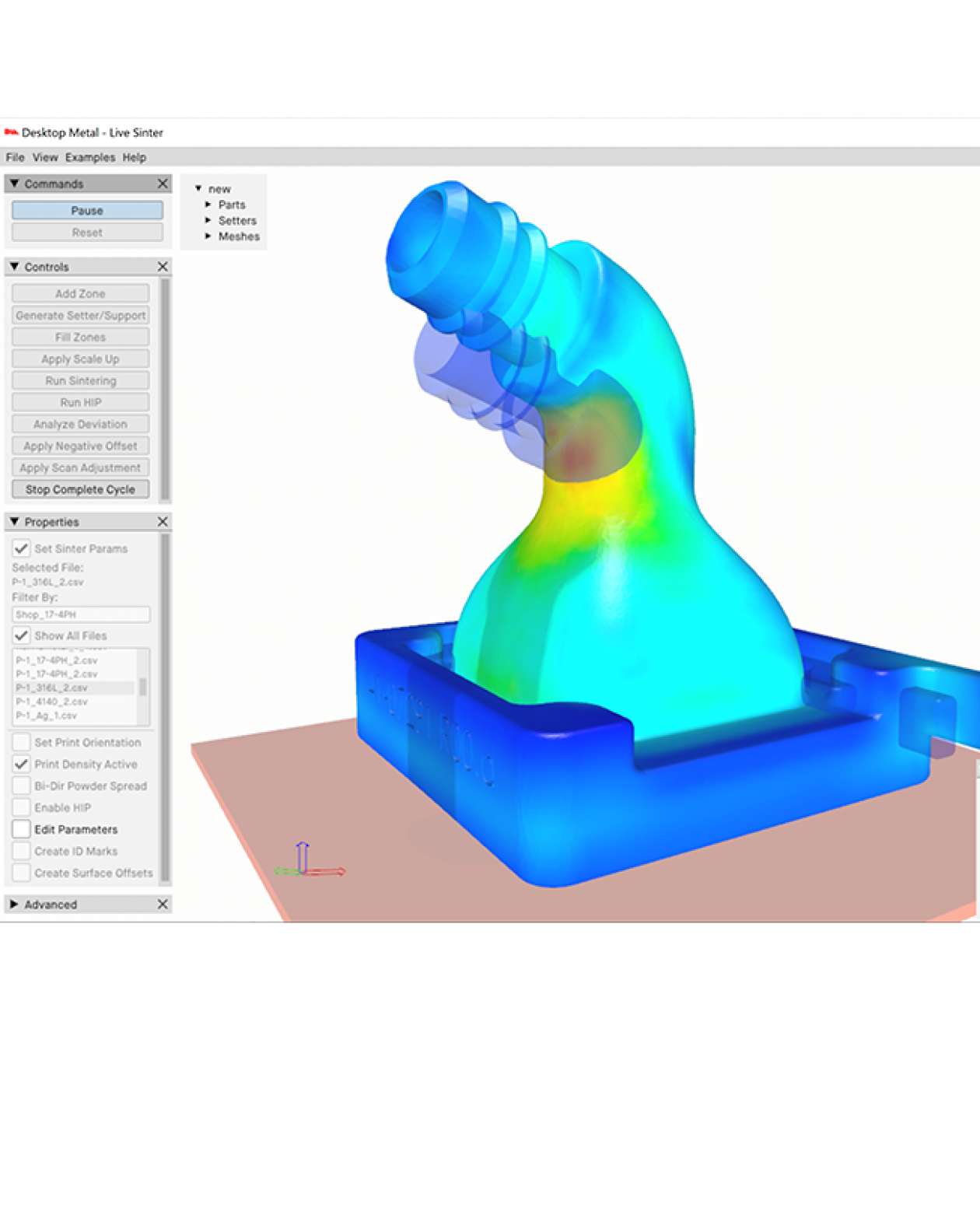

Sintering Simulation and Distortion Compensation

Desktop Metal developed a solution to generate distortion compensated geometry, also known as negative offset geometry, where the original geometry is scaled up and counter warped so, when sintered, the final part aligns with the required specification. Live Sinter iterates the process of tweaking the negative offset, compensating for unsupported regions and overhangs to eliminate the need for internal supports as well as help counteract the effects of drag or warp distortion.

Live Sinter performs simulation of the shrinkage and distortion of a metal part that takes place during sintering. The application models non-linear shrinkage, friction, elastic and plastic deformation, as well as density variations caused by powder spreading. Interactive simulations provide in-depth views of factors like stress, strain, and powder density. Live Sinter supports specification of different print and sintering orientations for both metal-based parts and supports, in dynamic contact with each other, along with ceramic setters of any shape.

Live Sinter exports high fidelity negative offset print-ready parts that preserve fine details from the original CAD design, such as surface textures, small features, and sharp edges. Working with Live Sinter helps ensure geometry mating surfaces perfectly match negative offset part surfaces where they come into contact.

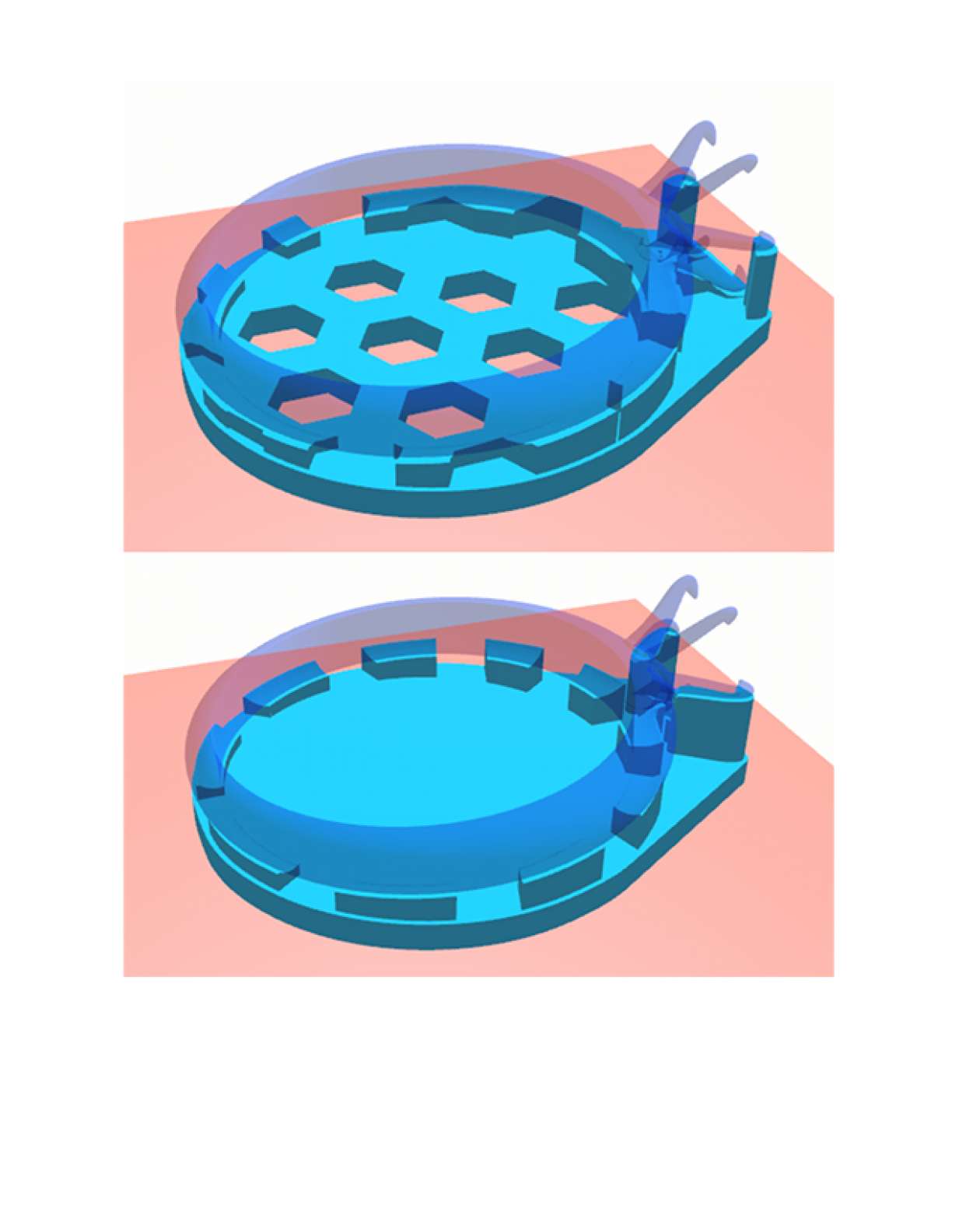

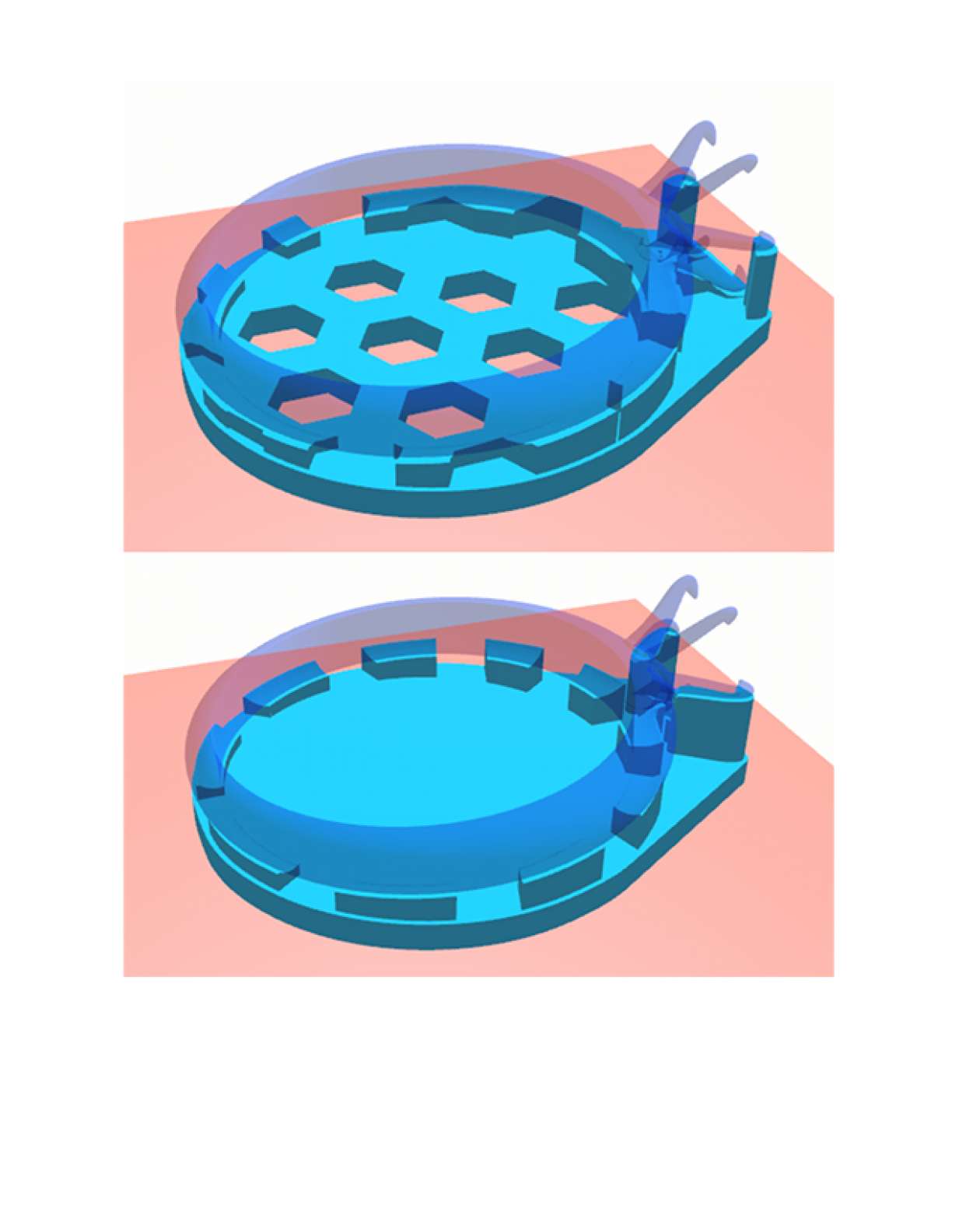

Optimized Support Generation and Surface Offsetting

Live Sinter provides optional support generation optimized to significantly reduce material usage while enabling distortion compensation to occur where needed. Users interactively generate supports in a variety of sinter orientations while analyzing support volumes and stability characteristics as part of a trade-off analysis. Surfaces to be offset for downstream machining operations may also be specified for integrated manufacturing operations.

Live Sinter accepts CAD data in STL, STEP, and Parasolid formats, and is able to perform automated surface feature extraction, simplifying surface offsetting operations on faceted parts. Shrinkage due to Hot Isostatic Pressing (HIP) heat treatment can also be compensated for with Live Sinter software.

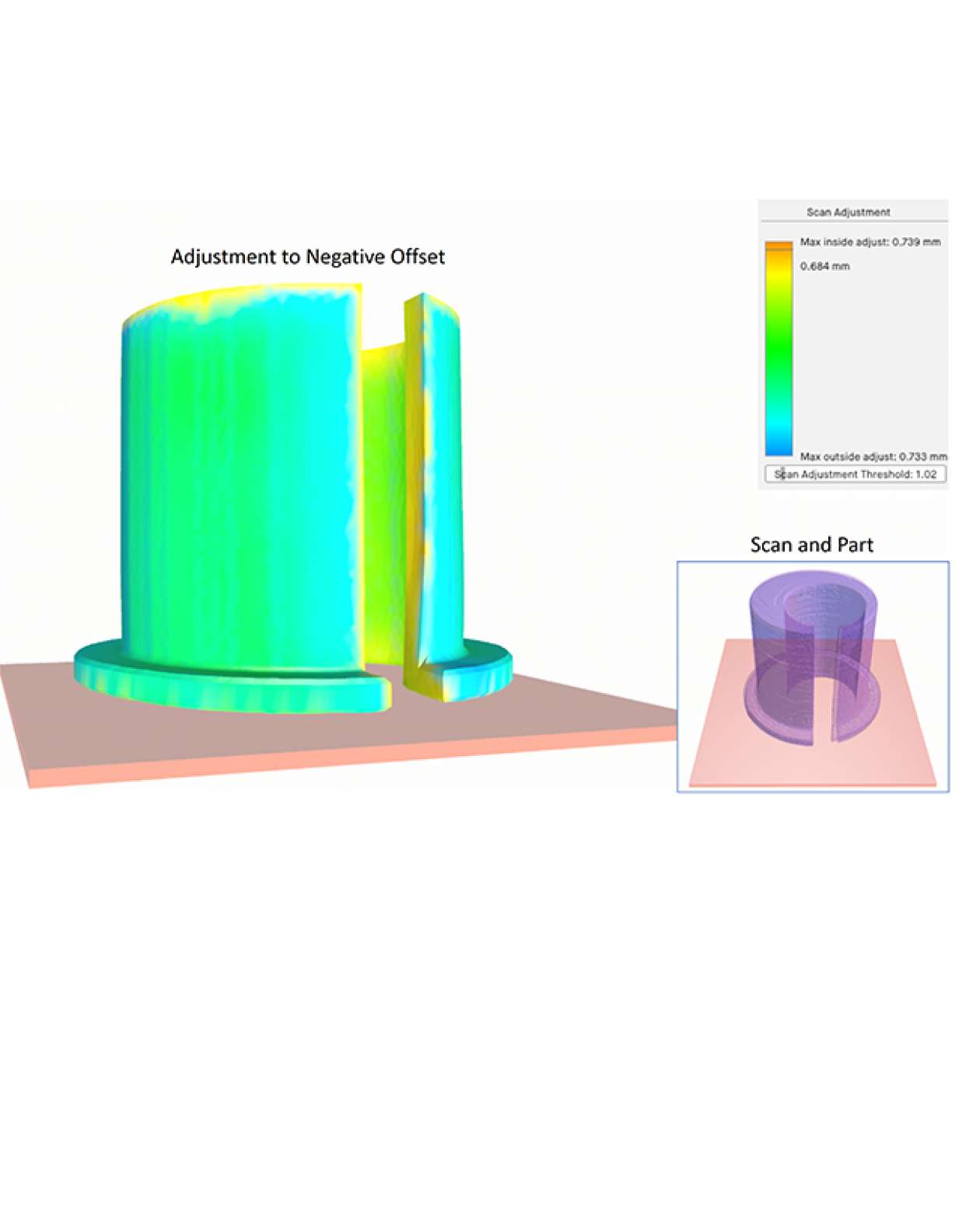

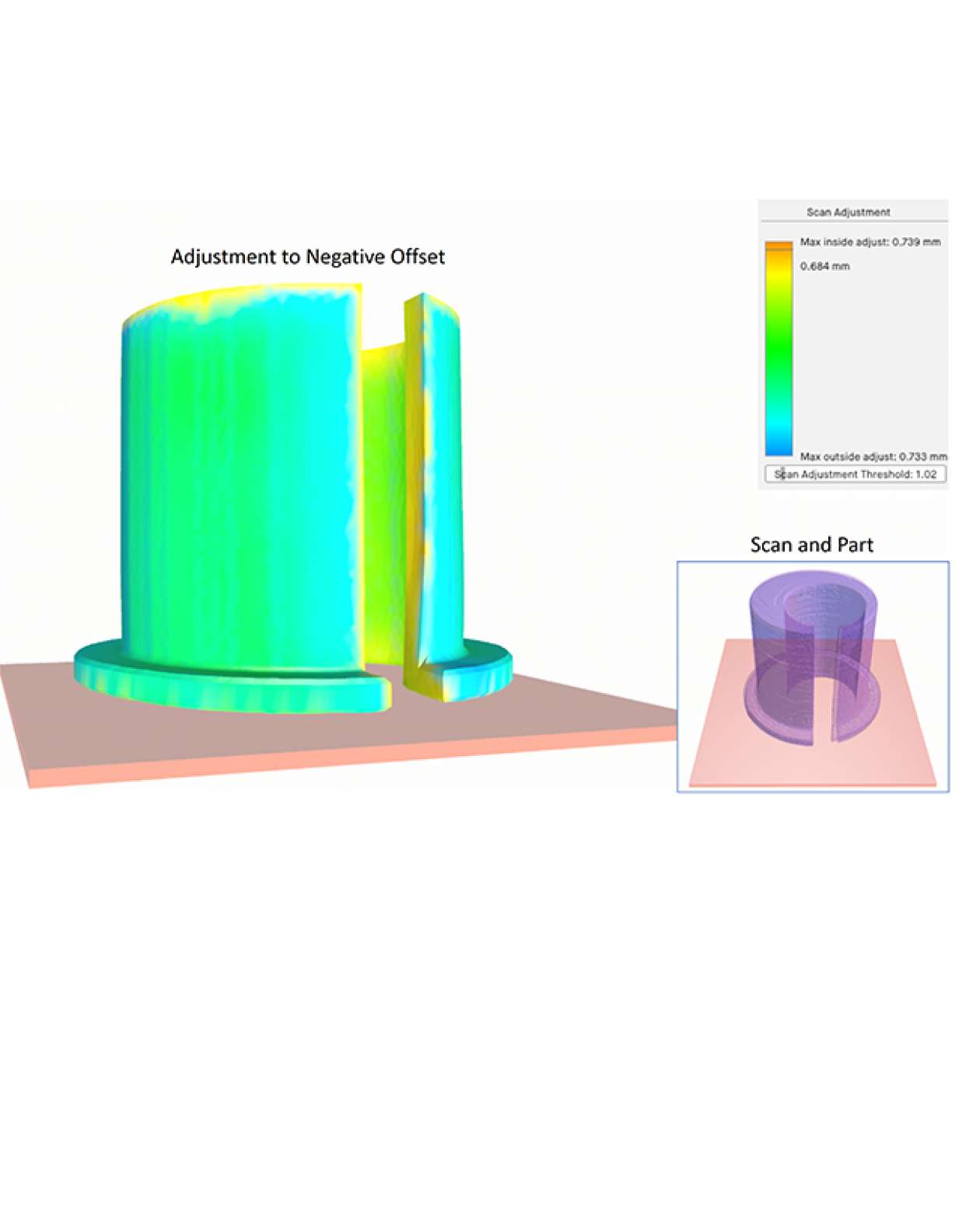

Scan-Based Adjustment for Fine Tuning

Live Sinter’s powerful multi-physics simulation and compensation software delivers sinter-ready, printable geometries that maintain tight shape and dimensional tolerances. After scan-based adjustments, Live Sinter enables correcting for complex distortion effects, yielding parts that consistently fall well within 1% of target dimension with as low as +/- 0.3% deviation, avoiding distortion, warping, and other common sintering challenges, as well as the cost and time associated with supports or setters.

Scan adjusted parts may then be printed and sintered again to reach even tighter tolerances. Parts may be scan adjusted multiple times to reach higher levels of accuracy. Scan adjustment works over the volume of the part, ensuring that thin walls and hidden interior regions move in concert with exterior regions.