Case Studies

-

-

Training Teachers for Hybrid Manufacturing

Discover the advanced training program that covers both theory and practice of combining AM and CNC, along with its associated benefits. This program was meticulously developed by Hohentwiel-Gewerbeschule Singen (HGS) in collaboration with SolidCAM Additive. Learn why the Studio System BMD 3D printer was chosen for printing metal parts in this training.

-

Exceptional jewelry and fashion accessories thanks to metal binder jetting

Legor, an Italian specialist in precious metals science, uses Desktop Metal's binder jetting technology to produce high quality platinum objects and products in other materials, as well as for R&D purposes. Learn how Legor benefits from this innovative manufacturing approach.

-

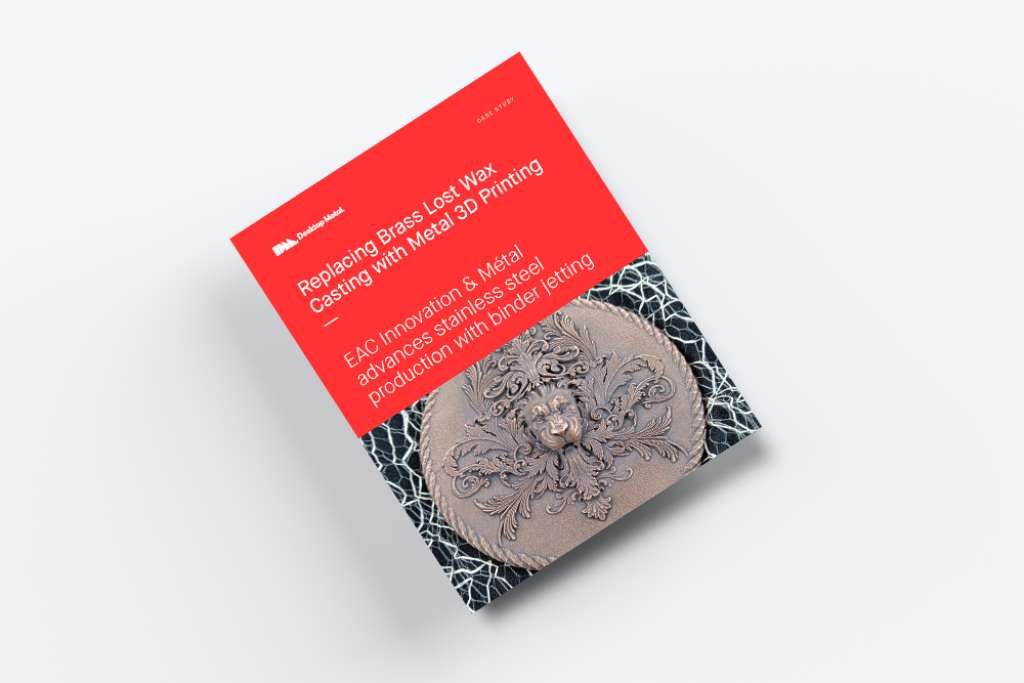

The benefits of replacing brass lost wax casting with stainless steel 3D printing

EAC Innovation & Métal eliminates brass lost-wax casting in favor of stainless steel production with binder jetting. Learn how this strategy enables higher repeatability and precision, greater design flexibility, faster prototyping and production, as well as more efficient material use, less waste and lower energy requirements.

-

-

-

Canopy Aerospace is unlocking the space economy with binder jet 3D printing

Canopy Aerospace leverages binder jet 3D printing to revolutionize thermal protection systems for space, defense, and automotive industries. Learn how this innovative approach reduces lead times, eliminates traditional tooling, and enables flexible production of complex ceramic components.

-

Cambrian R&D students operate safe, powder-free metal 3D printer for applied research and development projects

Cambrian R&D, the applied research division of Cambrian College, partners with regional businesses to serve as an engineering house and demystify new technologies. Adopting the Studio System as it's first metal 3D printer allows student operators to work on customer projects like wheel hubs for the drivetrain assembly of an all-terrain rover.

-

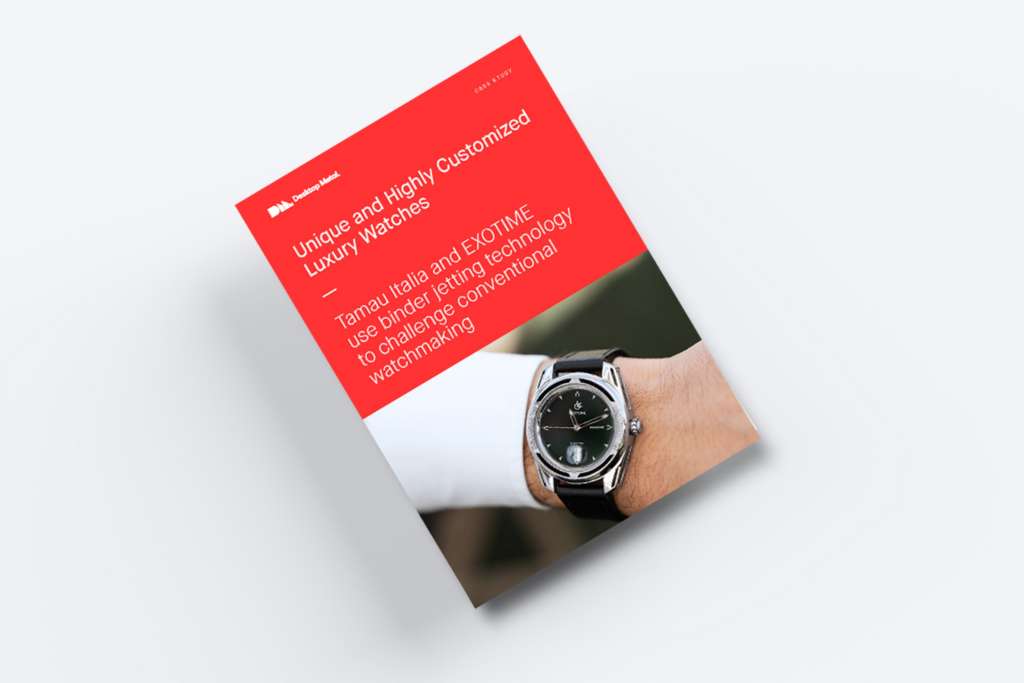

Unique and Highly Customized Luxury Watches

Exotime and Tamau Italia use metal binder jetting technology to challenge conventional watchmaking and efficiently produce complex watch parts. Learn how this cutting-edge additive manufacturing technology enables easy, fast, and cost-effective production of innovative luxury watch cases.

-

-

-

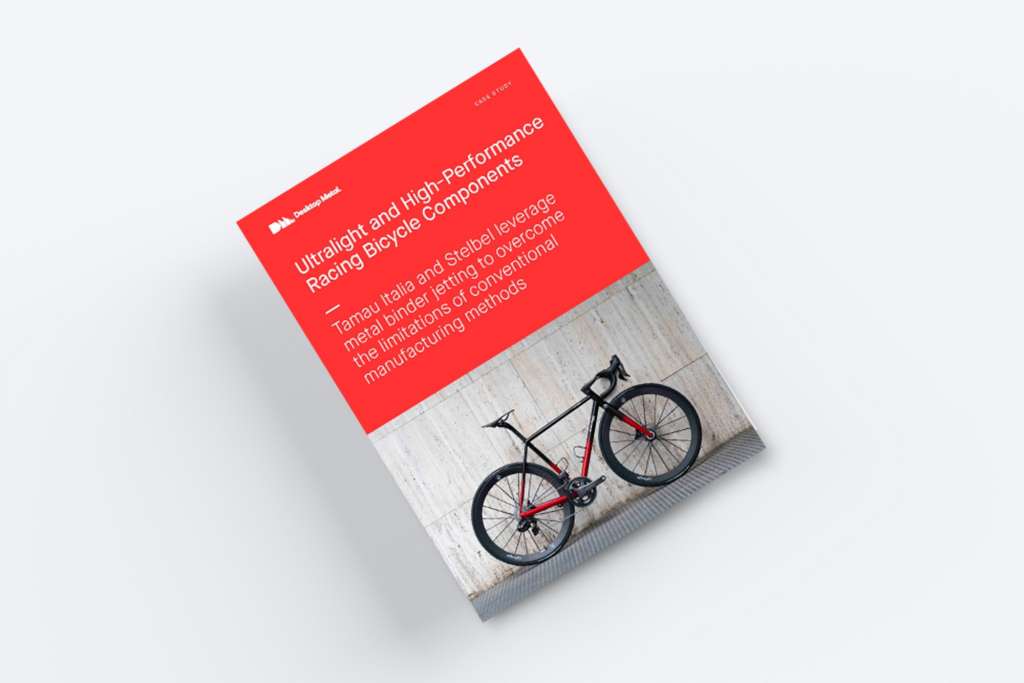

Ultralight and High Performance Racing Bicycle Components

Tamau Italia and Stelbel leverage metal binder jetting to overcome the limitations of conventional manufacturing methods (CNC, investment casting, and metal injection molding). Learn how metal binder jetting improves the performance and reduces the weight of the rear dropouts for Stelbel's racing bicycle frame, while significantly reducing the production time and cost of the parts.

-

C.J. Moyna & Sons earthmoving experts use the Shop System to decrease supply chain risks and bring better products to market faster

By investing in a Desktop Metal Shop System™ CJ Moyna now uses metal 3D printing for rapid prototyping in R&D, product improvement, and antique restorations. Learn more in the case study.

-

BYU uses the world's most researched binder jetting platform to study the fundamentals of the metal 3D printing process

While many research labs are dedicated to new material development or post-processing optimization, the team at Brigham Young University studies the printing process itself in steps like the spreading of the powder layers. The InnoventX is the perfect tool with the flexibility to meet the needs of the team's research.

-

-

-

Bike Bling: 3D-Printed Metal Bicycle Accessories

Hex Components, an innovative English start-up makes high-end, stunning bike accessories with metal binder jetting. The components are 3D-printed on the Desktop Metal Shop System by 3D printing service bureau, EAC Innovation & Métal in France. Using the Desktop Metal Shop System Hex Components can offer personalized bike accessories with intricate details to their customers. Metal binder jetting enables the production of various designs without any tooling, cutting down on steps and costs making custom part creation simpler, quicker, and more affordable.

-

BAK Kohler Medical Technology combines metal binder jetting and CNC machining

By investing in a Desktop Metal Shop System™ BAK Kohler is able to reduce machine time and produce surgical instruments with complex geometries. Learn more in the case study.

-

Bridging to MIM production and opening smaller batch business with metal 3D printing

Alpha Precision Group, APG, uses binder jet 3D printing for an existing metal injection molding (MIM) customer to avoid the cost of tooling and produce a lower-volume design targeting a more niche market.

-

-

-

Bridge Appliances 3D Prints Rapid Innovations to Disrupt the Food Processing Sector

Bound Metal Deposition on the Desktop Metal Studio System allows Bridge Appliances to level the playing field in food processing innovation

-

SDSU studies the anisotropic microstructures of binder jetting with the InnoventX

The Powder Technology Laboratory explores undamental understandings of sinter-based additive manufacturing with the InnoventX

-

AM 2.0 technologies at Red Deer Polytechnic supports students and business development

Red Deer Polytechnic in Alberta, Canada, adopted an InnoventX for binder jetting metal and technical ceramics as well as an ETEC Xtreme 8K for elastomers.

-