Shop System™

The world’s first metal binder jetting system designed to bring metal 3D printing to machine shops. In addition to the turnkey standard system, Desktop Metal also offers the Shop System™+ and Shop System™ Pro packages for added flexibility, functionality, and value. The Shop System Forust Edition is also available for wood.

-

— 01

Easy to use & operate

-

— 02

Unparalleled productivity

-

— 03

Best in class print quality

-

— 04

Packages for every user

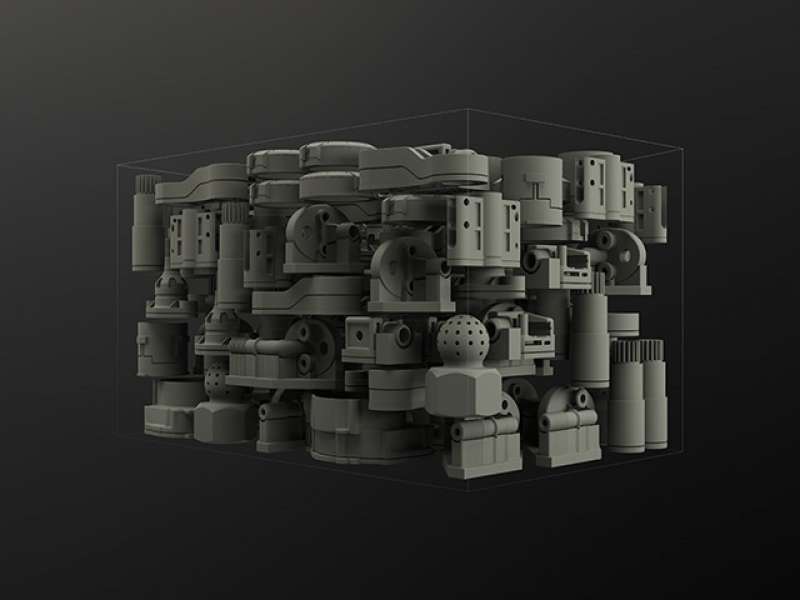

The Shop System™ introduces high quality binder jetting to an entirely new market of machine shops. Shops can now cost effectively 3D print end use metal parts with unparalleled speed and productivity.

Easy to use & operate

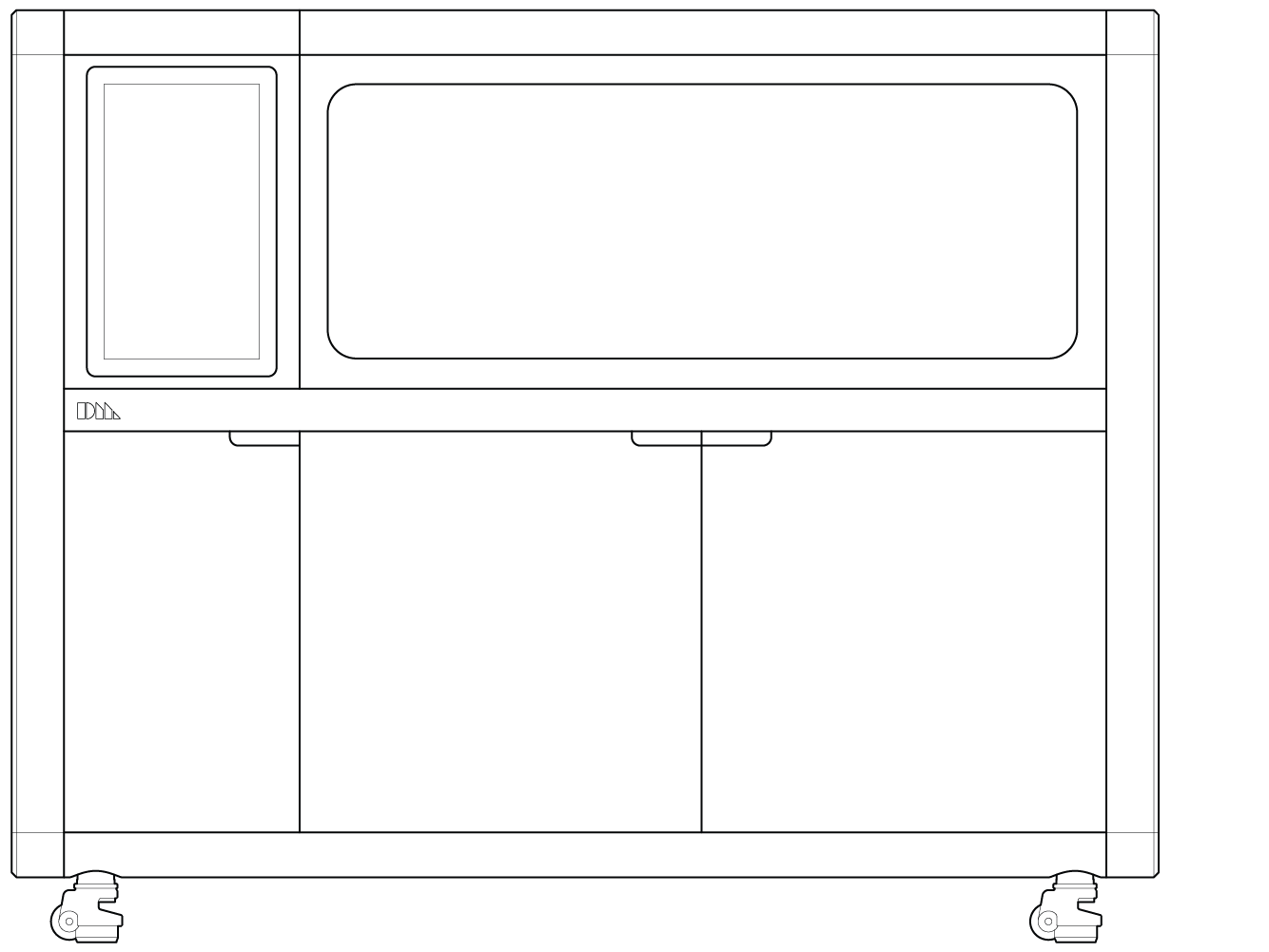

Designed with the modern machine shop in mind, the Shop System™ is built to fit seamlessly into your workflow. Produce parts with superior surface finish and resolution versus laser-based 3D printing systems at a fraction of the cost.¹

Affordable turnkey solution

The Shop System™ contains all the equipment your machine shop needs to begin binder jetting — from print through sintering. And with a range of build volume configurations (4L, 8L, 12L, and 16L), the Shop System™ is designed to scale to your shop’s throughput.

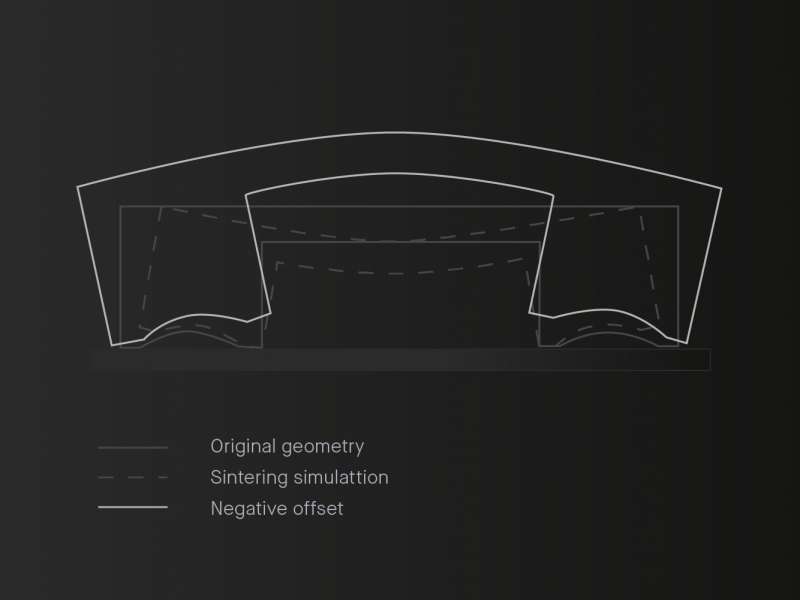

Download BrochureEasy Sintering with Live Sinter™

Take the guesswork out of sintering printed parts. Live Sinter™ tackles the decades-old problem of part shrinkage and distortion through predictive counter-deformation. The software simulates the complex forces parts experience during sintering and automatically adjusts the geometries that, once printed, will sinter to the original, intended design specifications

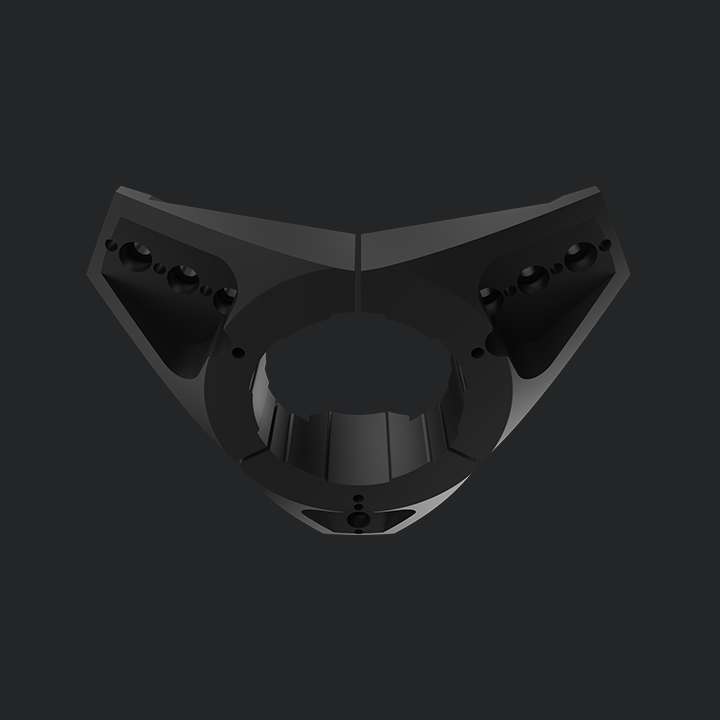

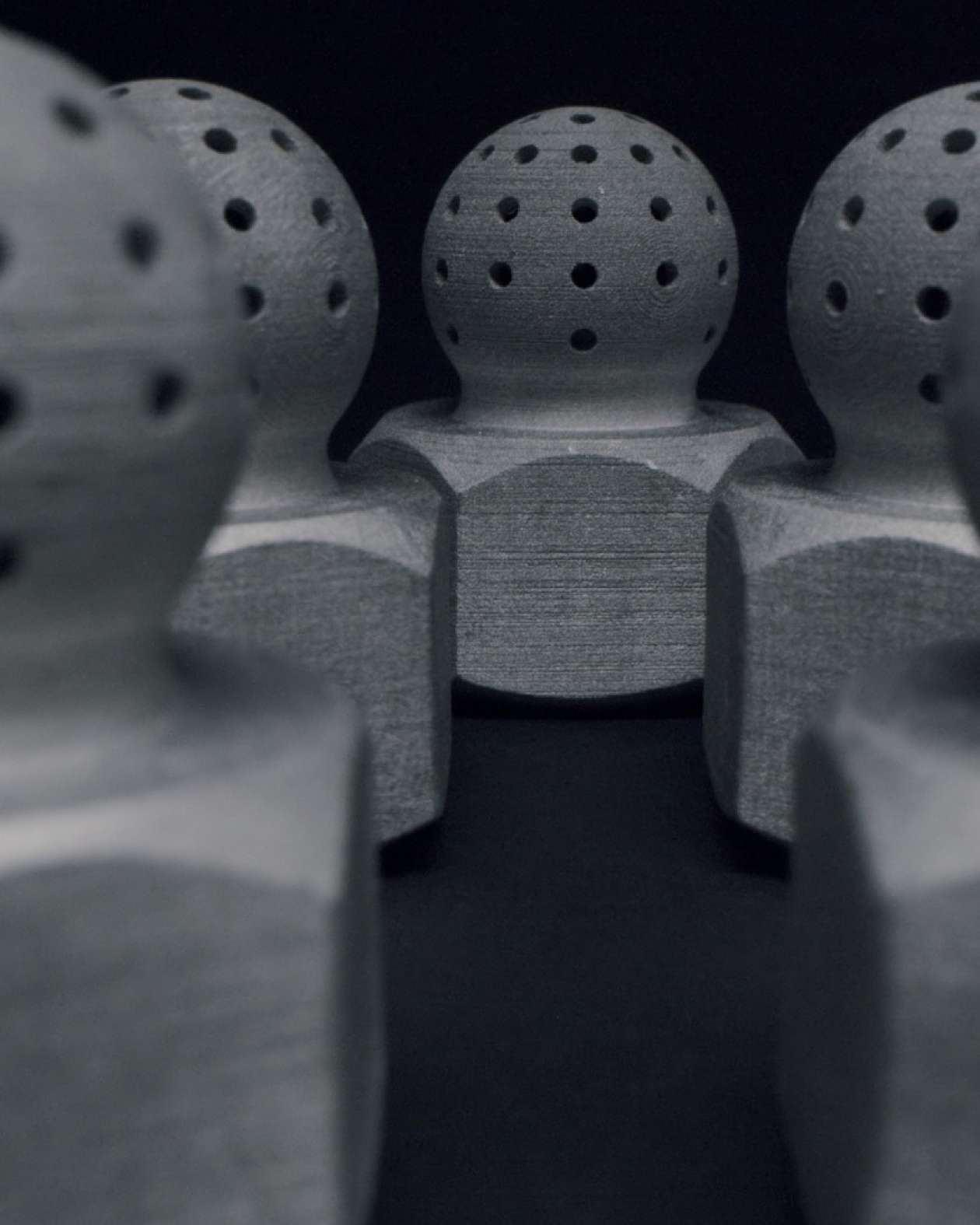

Learn MoreSimplified post-processing

Parts on the Shop System™ print fully supported in their powder bed, and feature hand-removable sintering setters. Avoid hours of labor machining off support structures typical to laser-based 3D printing systems and instead achieve customer-ready, near-net-shape parts right out of the furnace.

Optimized powders & parameters

Get started quickly with a turnkey, end-to-end 3D printing solution. The Shop System™ features Desktop Metal-engineered powders and processing parameters, optimized to deliver exceptional part quality and ensure part-to-part repeatability.

Unparalleled Productivity

Use 3D printing to amplify your shop’s output. Effortlessly print end-use metal parts with the quality, surface finish and tolerances required to co-exist with machining.

10x the speed

With a high-speed, single-pass print engine, the Shop System™ produces high-quality metal parts at up to 10x the speed of laser powder bed fusion systems⁴—meaning you can 3D print up to hundreds or thousands of metal parts per day.⁵

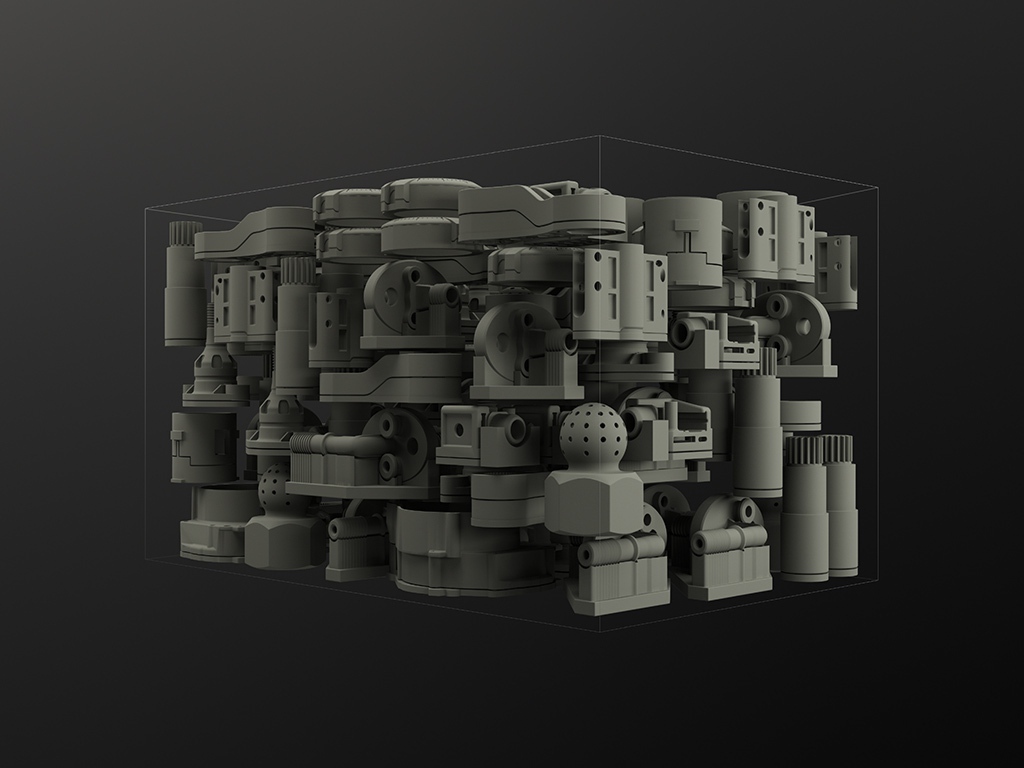

Print a build per shift

Average cycle times of 6-12 hours enable a new build every shift.² With the ability to 3D print tens to hundreds of near-net shape parts each day, you can reserve machinist hours for refining critical features.

Flexible batch jobs

The Shop System™ is a tooling-free manufacturing process. Change over to a new job at the press of a button and process multiple complex jobs without the need for custom setups.

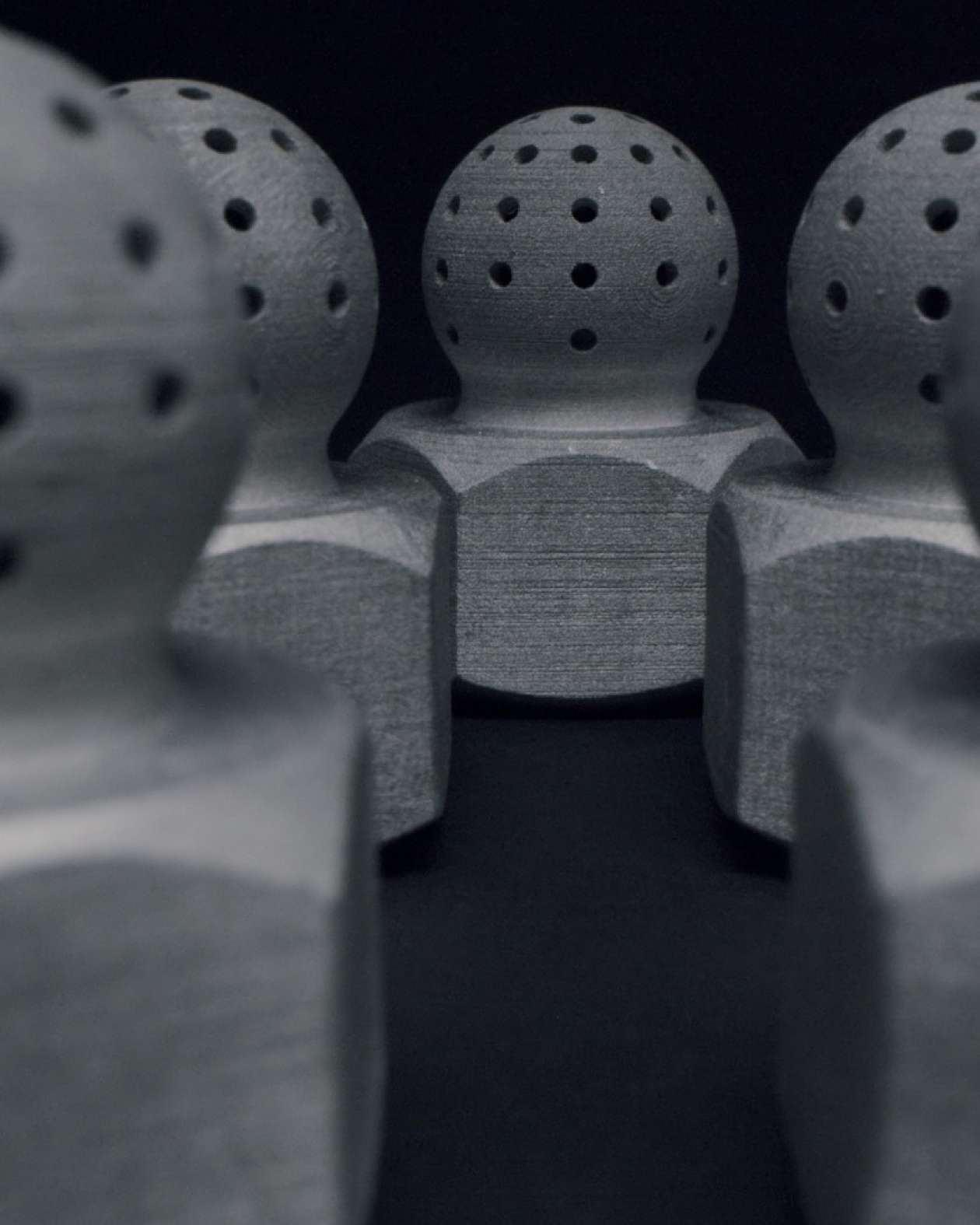

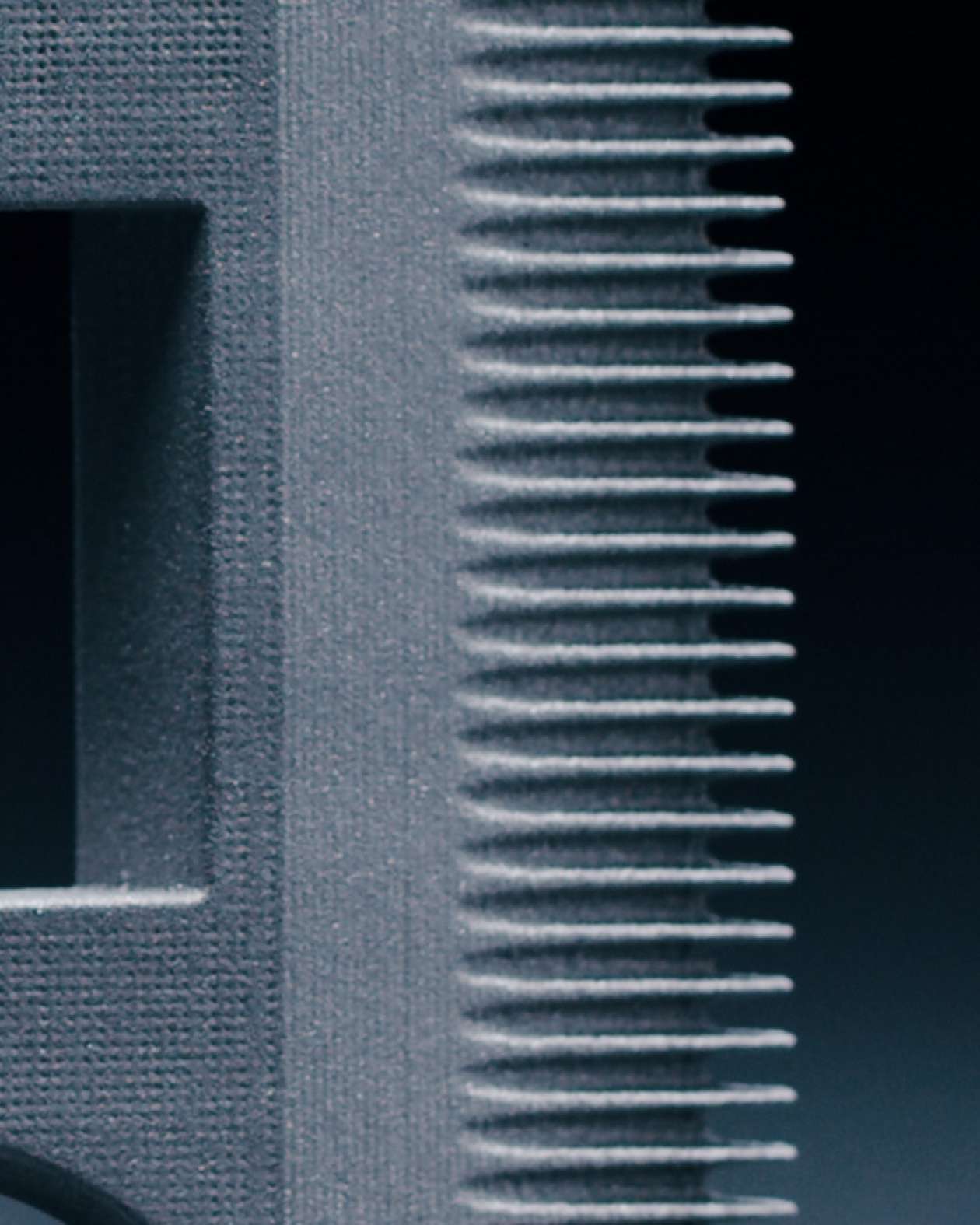

Superior print quality

Print customer-ready, high-resolution parts with incredibly fine feature detail. Achieve surface finishes as low as 4µm Ra out of the furnace. The Shop System™ produces dense, solid parts, no debind or infill required.

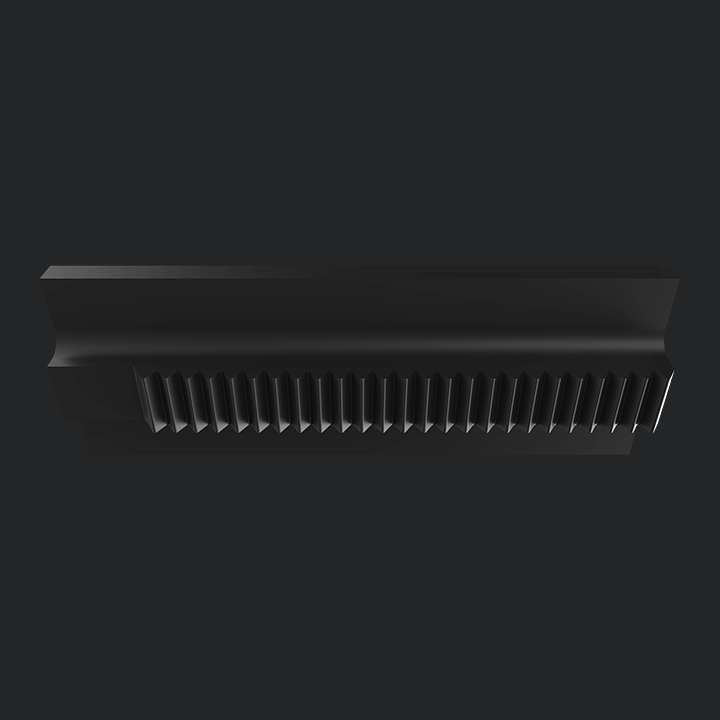

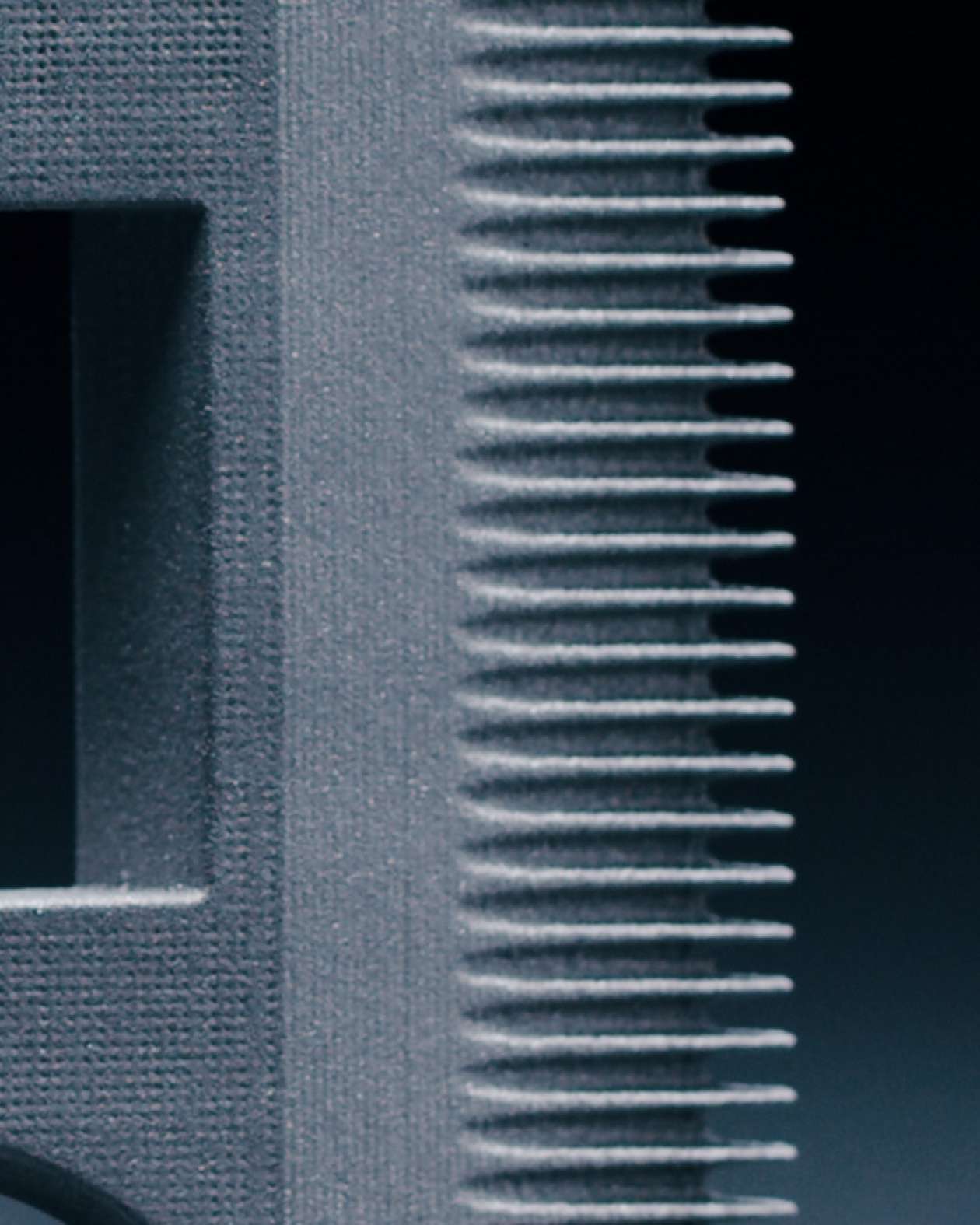

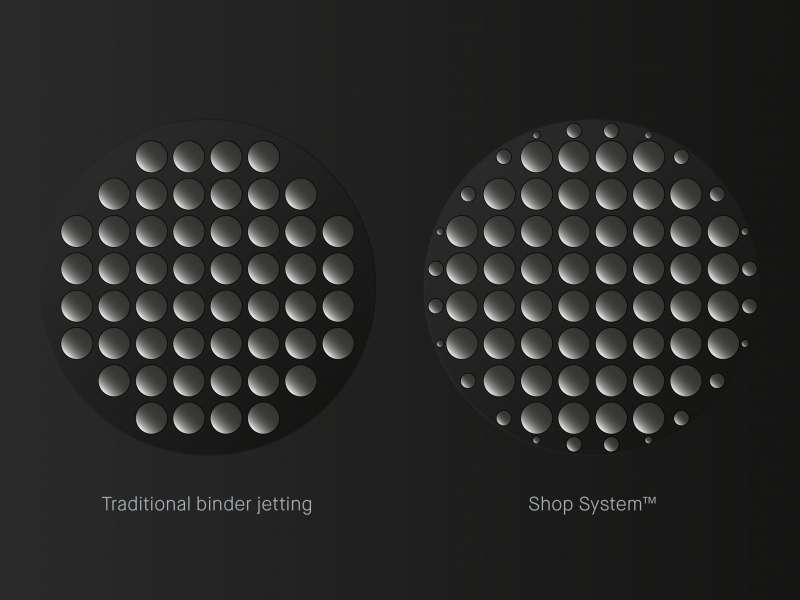

High-resolution printing

The Shop System™ features the highest resolution single-pass binder jetting system on the market. With 1600x1600 DPI native (33% higher resolution than comparable systems), and over 670M drops per second, the Shop System™ delivers high-speed, high-resolution 3D printing.³

Adaptive print engine

Users don’t have to sacrifice feature detail or resolution for speed. Employing a 1.2 pL droplet size and automated drop multiplexing up to 6 pL, the Shop System™ achieves superior surface finish, bleed control and rich feature detail at high speed.

5x print redundancy

To avoid jet-outs and print issues the Shop System™ features 70,000-plus nozzles spread across five rows. The printhead features 25% higher nozzle redundancy than comparable 3D printing systems, resulting in enhanced print quality and reliability.³

Flexible manufacturing

The Shop System™ is designed to seamlessly integrate additive manufacturing into your shop’s workflow to improve productivity across any range of manufacturing scenarios.

-

Mixed-volume production

Produce parts with different geometries simultaneously without the need for multiple setups. -

Batch production

Cost effectively 3D print low-volume batches of complex parts due to elimination of tooling. -

Mid-volume production

Produce hundreds of near-net-shape parts every day with dramatically reduced labor costs and expanded geometric flexibility.

How it works

The Shop System™ is an end-to-end, single-pass binder jetting solution delivering high-resolution 3D printed parts at a fraction of the time and cost.

-

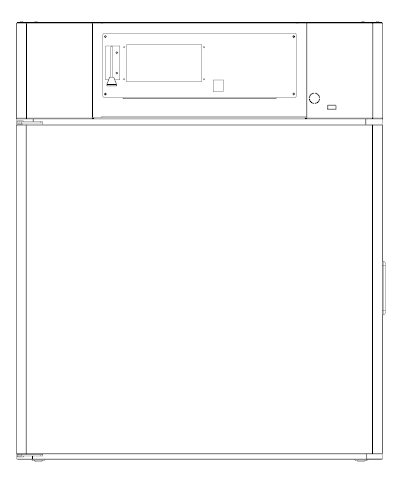

Print

For each layer, the printer spreads metal powder across the build bed, and precisely jets a binding agent to bond loose powder and define part geometry. Layer by layer, metal powder and binder is deposited until the entire build volume is packed with bound parts and surrounding loose powder.

-

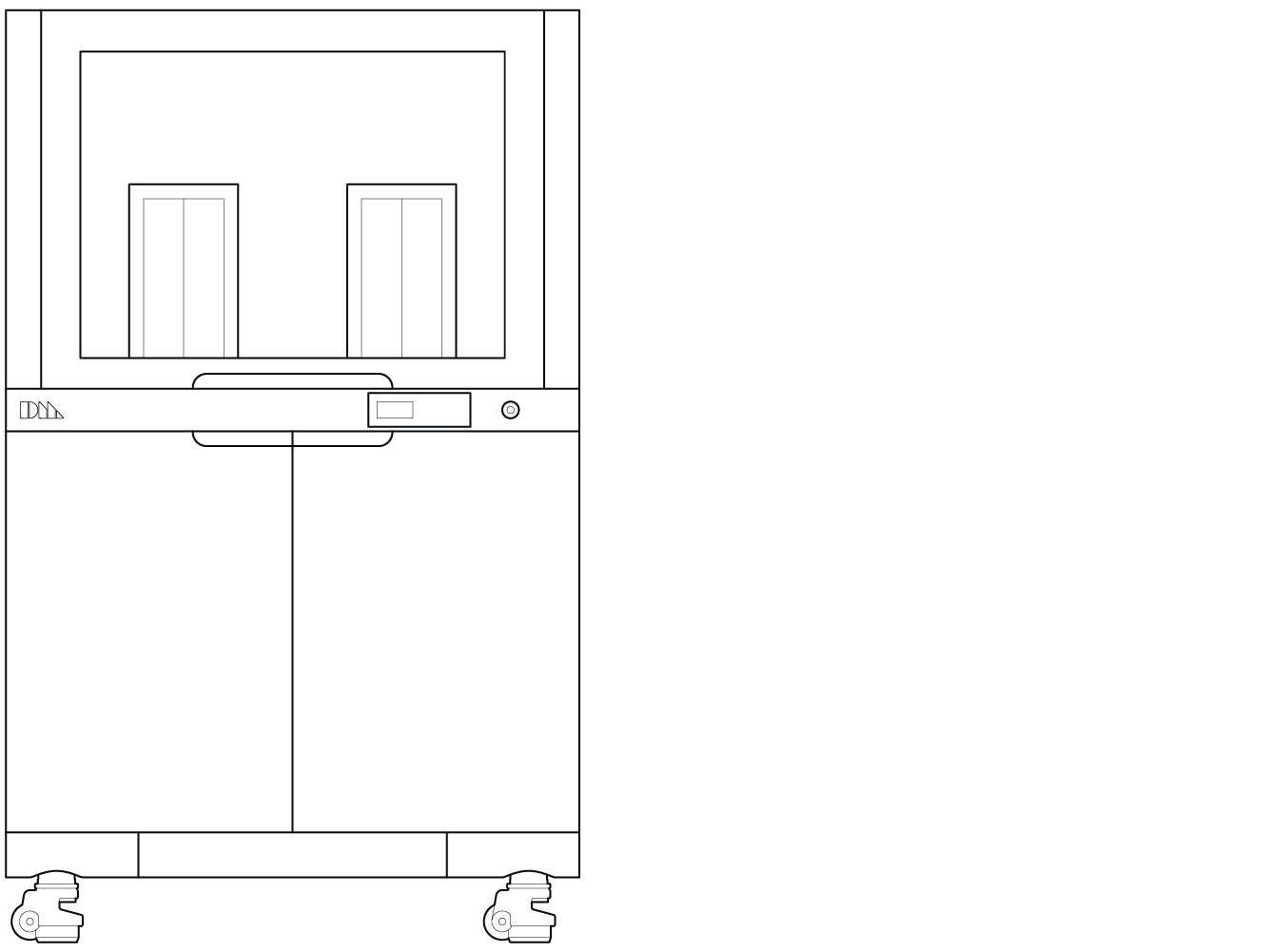

Depowder

Once an entire build is complete and has been crosslinked in the drying oven, the build box is removed and placed in a powder station for bulk and fine depowdering—with the help of a hand-held air pick. Loose powder is removed from the parts and recovered via a built-in powder recycling system with powder sieving.

-

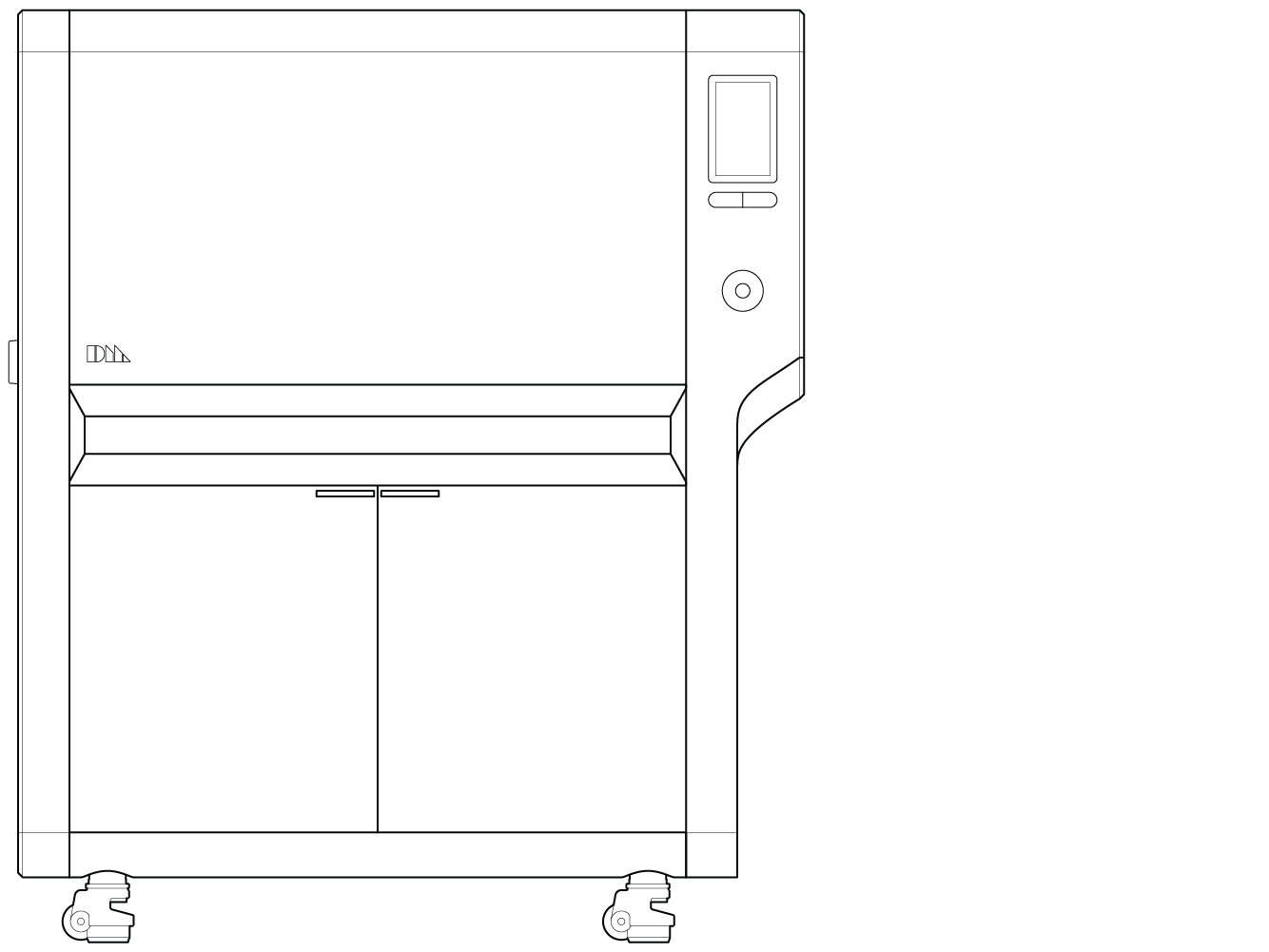

Sinter

Depowdered parts are placed onto trays in a shop-safe, high-throughput furnace for batch sintering. With an external gas hookup and temperatures reaching 1400ºC, the Shop System™ furnace is able to deliver quality and reliable sintering in a shop-friendly format.

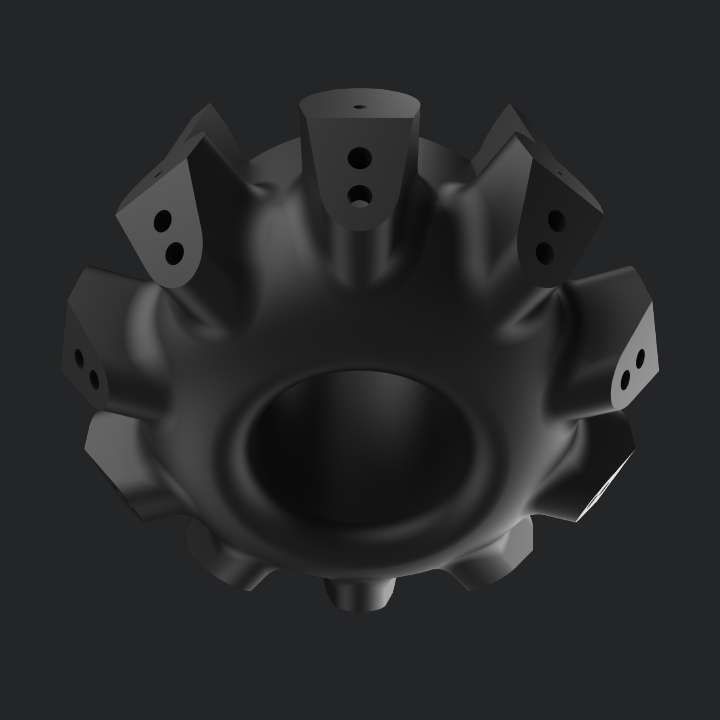

Part Gallery

Shop System™ applications span a variety of industries including manufacturing, tooling, automotive, consumer, electronics, and oil & gas.

Applications by Industry

Explore applications for 3D printing across a range of industries.

1. Compared to single-laser, mid-range Laser Powder Bed Fusion (LPBF) systems. Based on list price on 11.14.2019 of comparable laser-based systems. Comparison dependent on Shop System configuration (4L, 8L, 12L, or 16L ). May require additional furnace capacity if printing 24/7 at high packing.

2. Based on variables such as part size, part quantity, and layer thickness.

3. Based on published specifications for comparable metal binder jet systems as of November 14, 2019.

4. Based on published speeds of single-laser, mid-range laser powder bed fusion systems as of August 25, 2020.

5. Management Estimates as of December 7th, 2020.