Easy-to-use software to generate and optimize binder jetting builds for printing and sintering success

-

— 01

Build Generation

-

— 02

Slice Files for Printing

-

— 03

Generate Sinter Setters and Supports

Live Build MFG is a one-stop solution to prepare 3D printing models for any of Desktop Metal’s powder based printing solutions. Designed to help users print parts easily, quickly and efficiently, particularly those with limited experience with binder jetting build preparation.

Making part generation as easy as the click of a button, Live Build MFG software is an intuitive and powerful tool to prepare 3D models for printing on Desktop Metal binder jetting systems. Build success is enabled with automatic nesting, support generation, and slicing in a simple-to-use platform where users can configure part-specific settings to:

• Orient, position and scale models

• Select materials and suggested profile parameters or create custom profiles

• Automatically optimize fabrication to achieve high-quality parts

Compatible with both Windows and MacOS, Live Build MFG accelerates additive manufacturing production to ensure fabrication flexibility and process efficiency to produce quality parts without the need for extensively trained operators or extensive training.

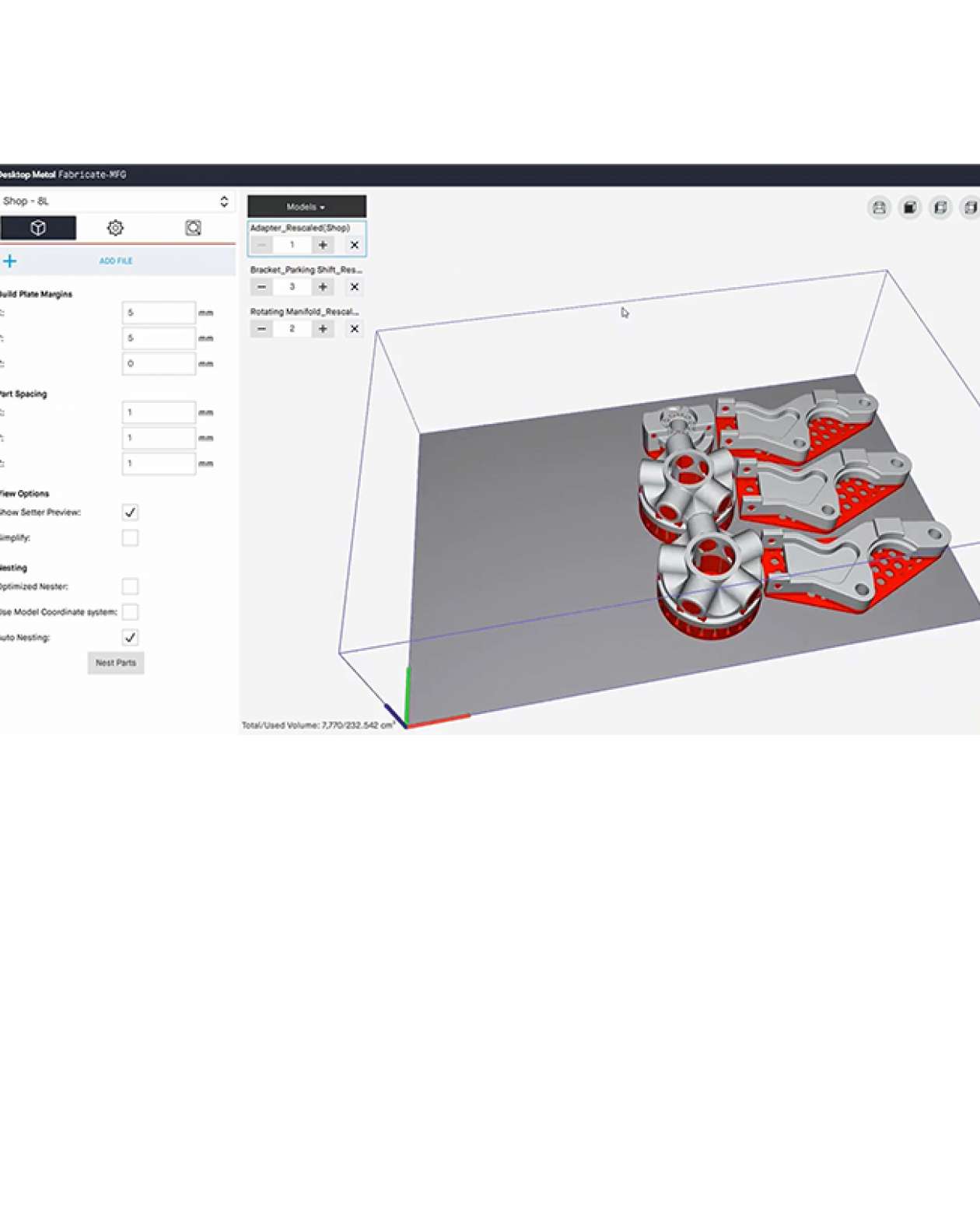

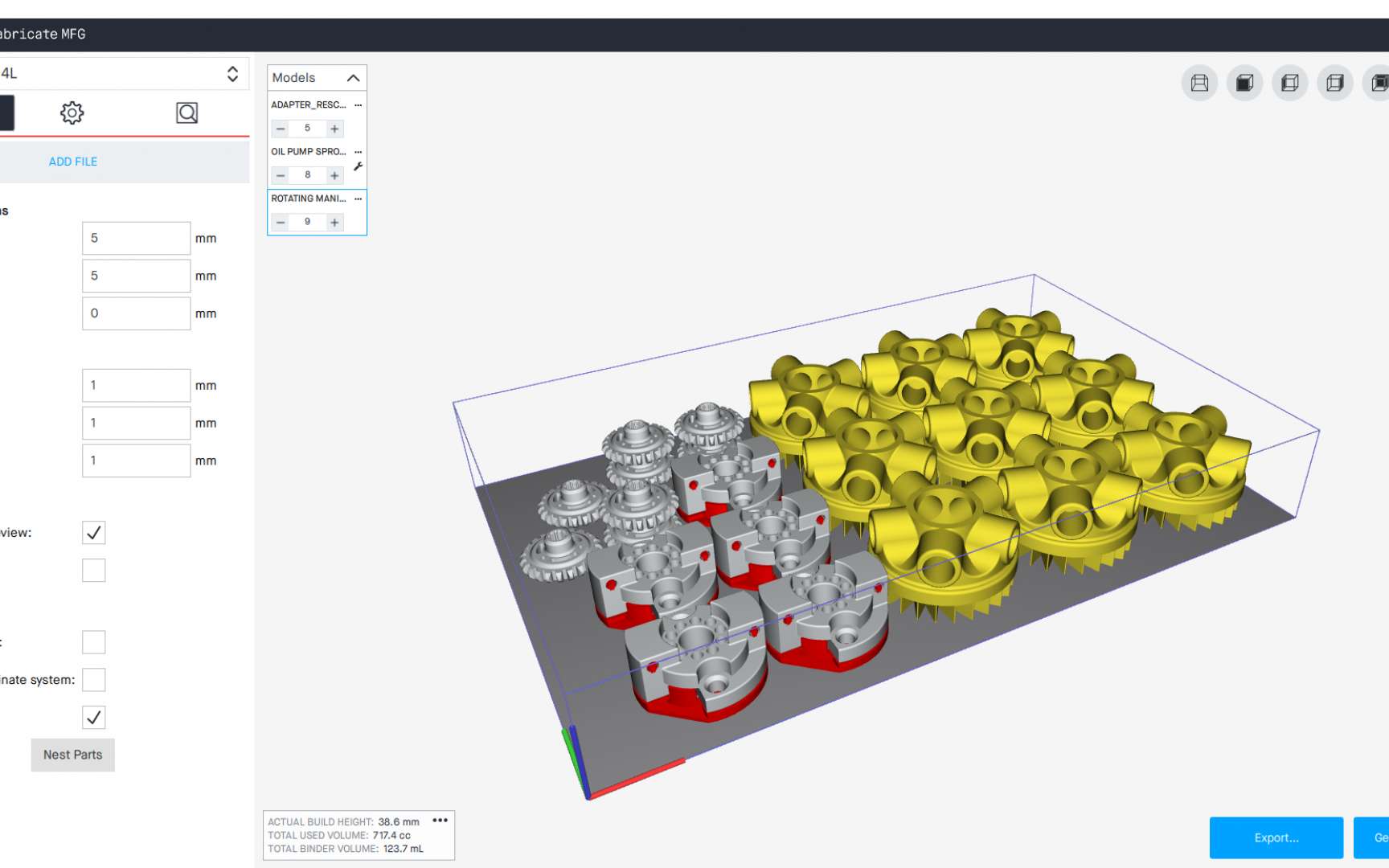

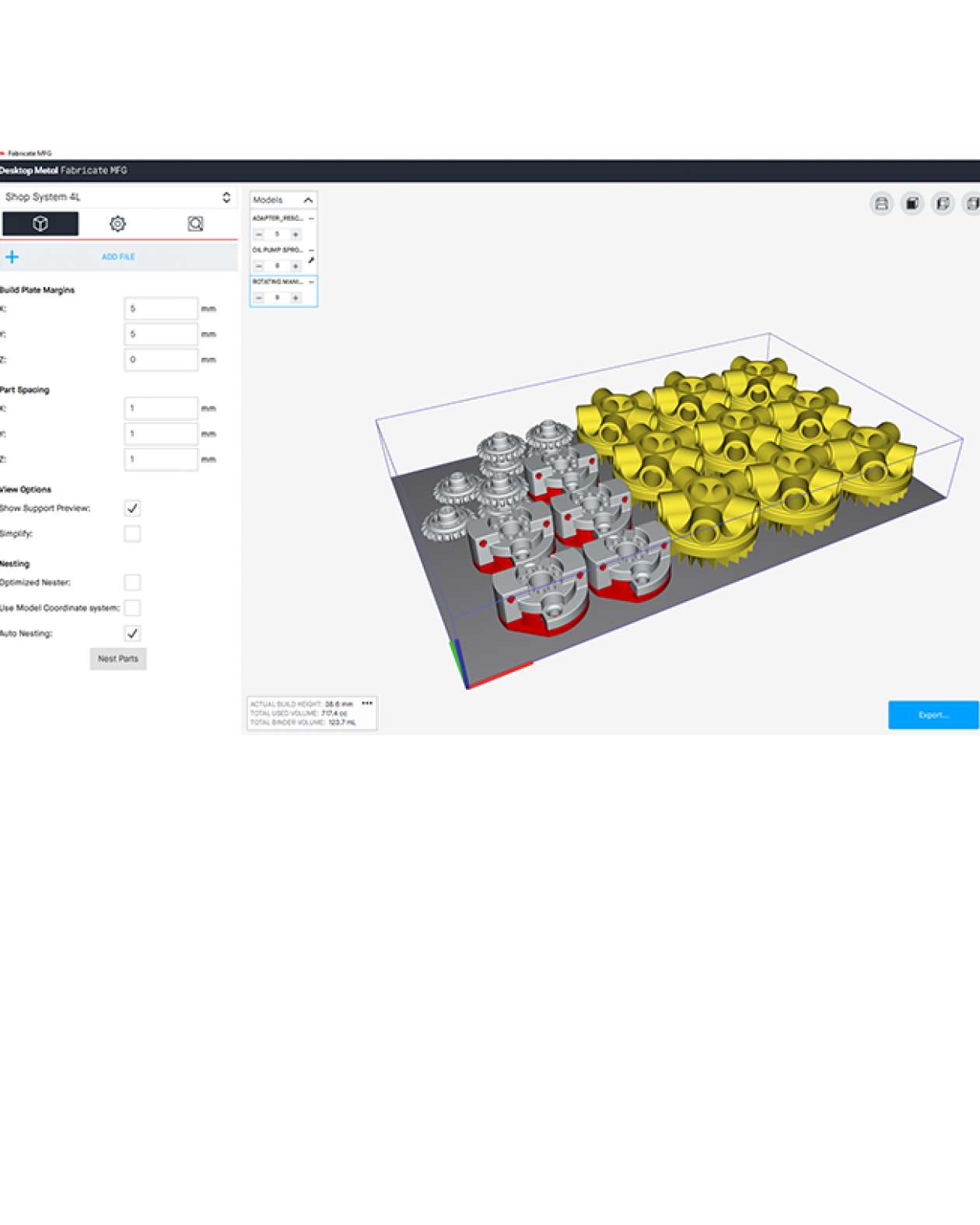

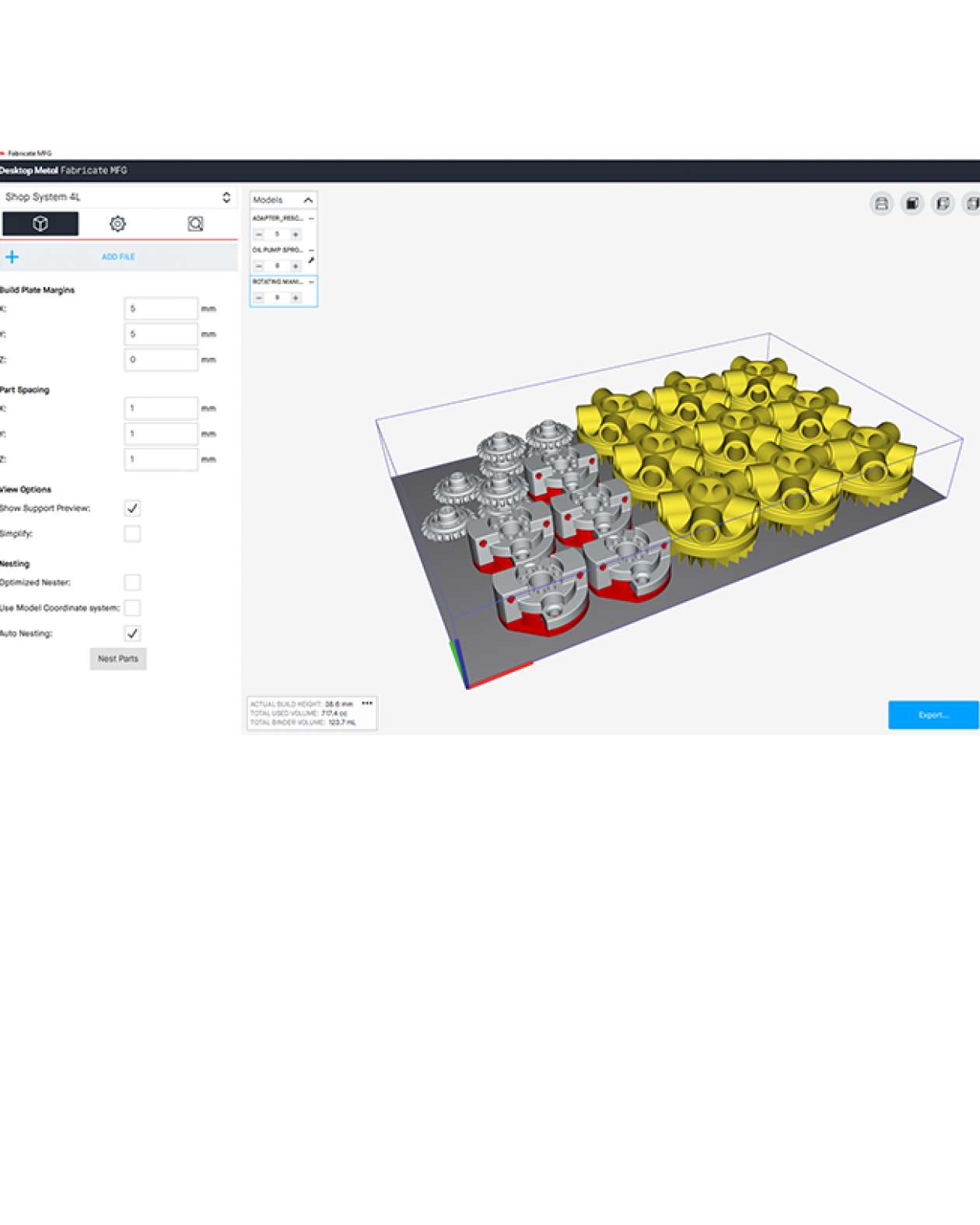

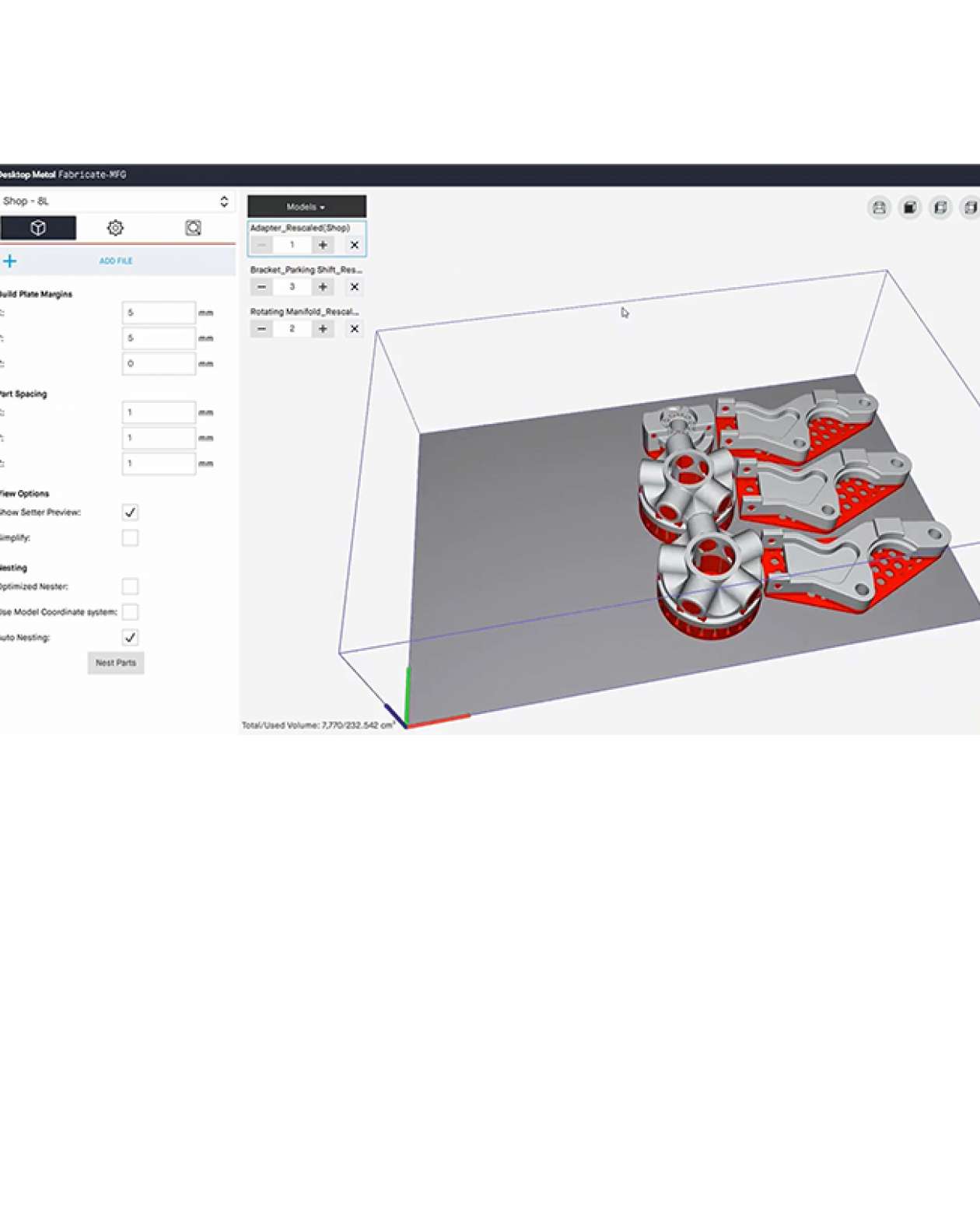

Build Generation

Upload your 3D model or CAD file into Live Build MFG and the software automatically nests your parts into the available 3D space to help users take full advantage of the build volume of their machine. Optimize part orientation for build success and optimized print times, or drag, rotate, and scale parts manually to customize builds.

Take advantage of the production flexibility of binder jetting and add various parts, stacking them into the same build job, or efficiently nest an entire box of production parts in a dense pack for successful printing and sintering.

Live Build MFG supports all major CAD formats and analyzes geometries to fix issues found with tessellated data. Already working with another program for build prep optimization? Live Build MFG recognizes files created with Desktop Metal Live Sinter™ to automatically import material parameter settings and users of other CAD tools can easily import pre-nested and scaled builds.

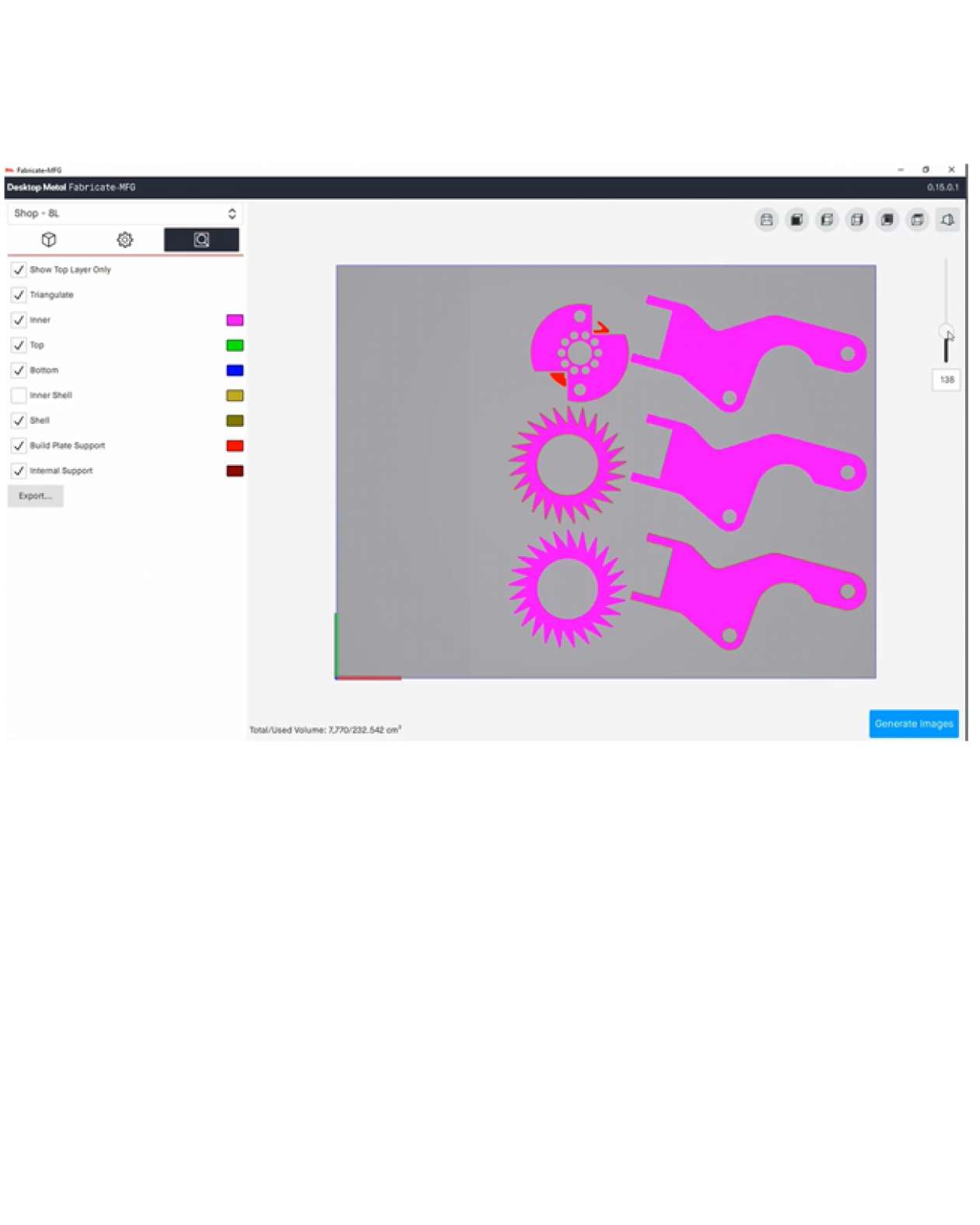

Slicing

Live Build MFG also creates an optimized job for your Desktop Metal binder jet systems. Cross-sectional images generate 2D slices for each print layer and generate images for the printer to read. The software creates an interactive preview for users to get a detailed understanding of the part’s internal structure while allowing layer-by-layer views of the build or of triangulated sections to review wall thickness, for example.

To ensure users have a full understanding of their build jobs, Live Build MFG calculates an estimate summary of print time as well as material and binder usage. Export data with cost estimation and pricing calculations by part and export individual parts or full build boxes for future production repeatability.

Support Generation

Live Build MFG aids users in preparing their parts for sintering with scale factor analysis and support generation to maximize part success while minimizing material usage during printing. To compensate for any deformation during sintering, Live Build MFG provides users with standard material settings and uniform scale factors to compensate for shrinkage in the furnace.

Sintering supports help control deformation when parts are in the sintering furnace. Live Build MFG highlights overhangs indicating areas where supports should be included, and users can select the degree by which the angle of faces will be supported and overhead angles that begin supports. Supports for sintering can be automatically generated with an optimized honeycomb pattern to minimize binder usage during the build and aid part removal and depowdering.