Rapid design exploration through real-time generative design.

-

— 01

Designs for the Real World

-

— 02

Easy Interactive Modeling

-

— 03

Manufacturing-ready Parts

Live Parts™ makes generative design easy. Simply set constraints and loading conditions and create optimized, manufacturing-ready models in a matter of minutes.

Designs for the Real World

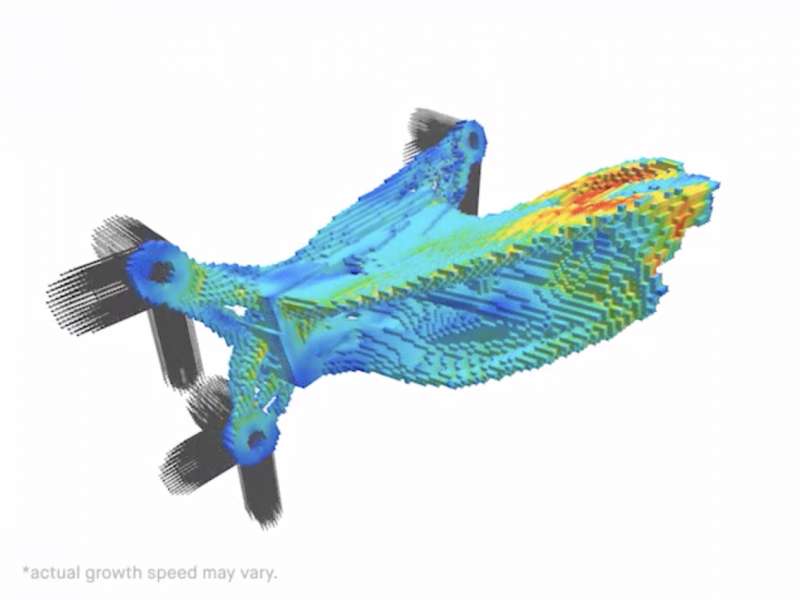

Live Parts™ brings the radical geometry of generative design into the real world. A combination of dynamic simulation and live finite element analysis results in parts that are highly optimized and able to stand up to both expected and unexpected conditions.

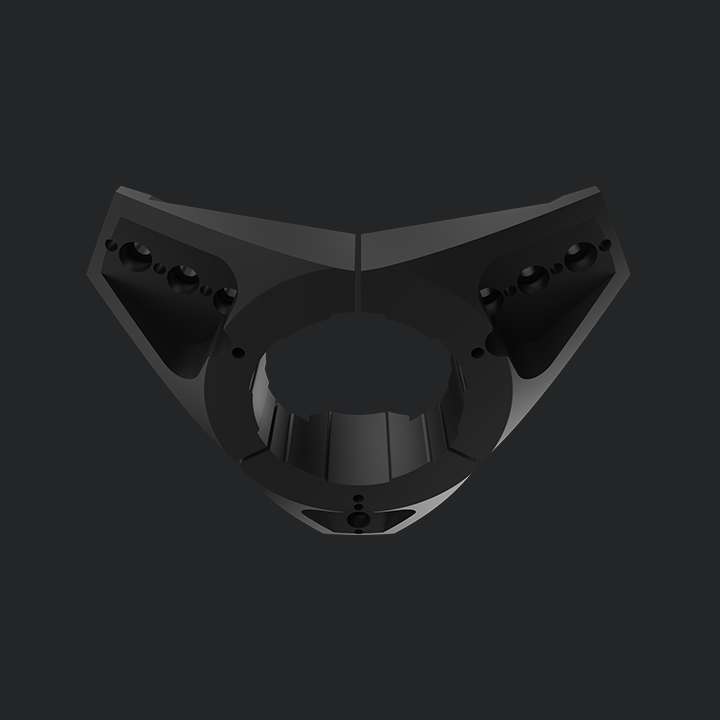

Optimized Parts

Part geometry is optimised throughout the generation process. Easily produce stable, optimized designs in a matter or minutes.

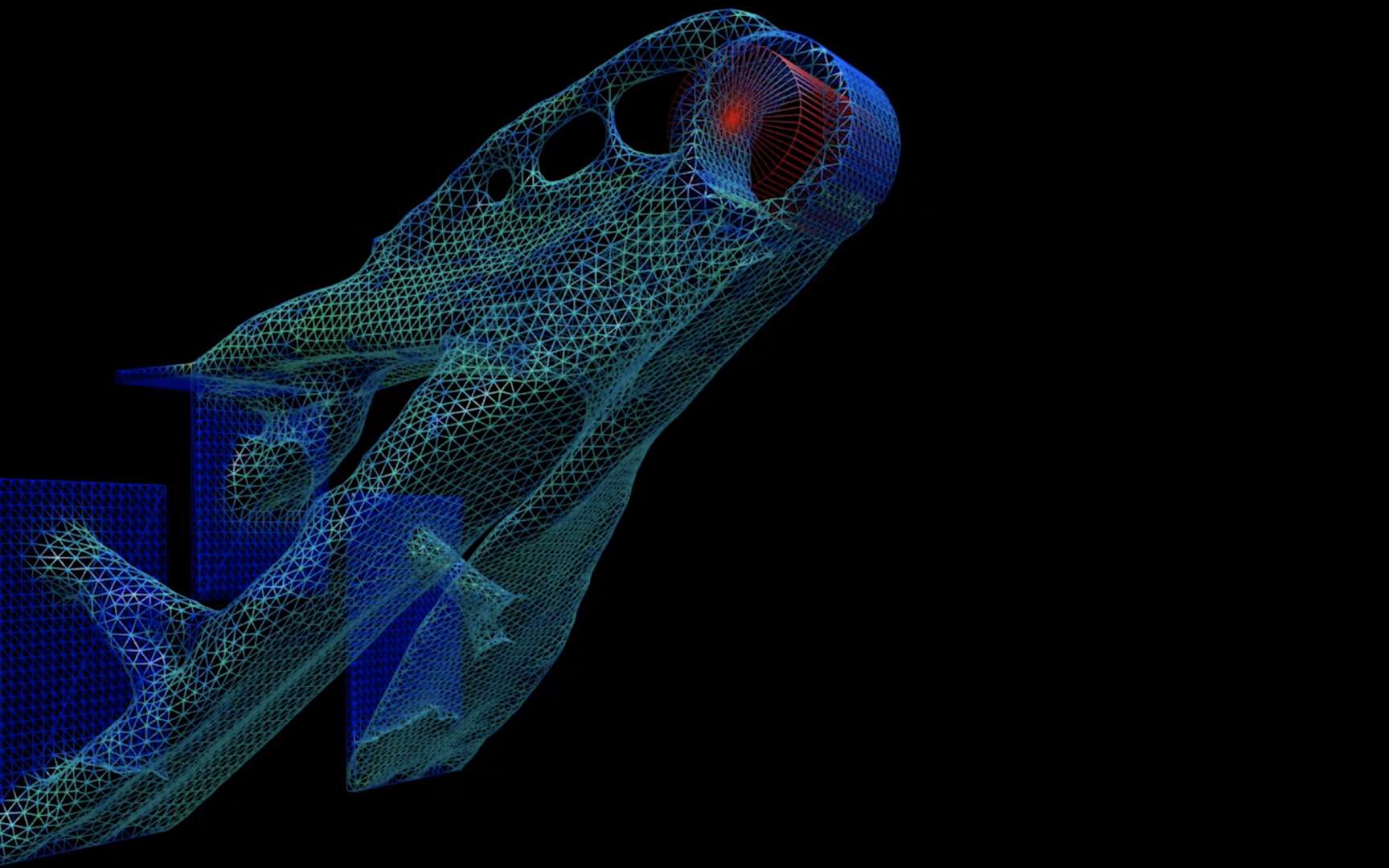

Dynamic simulation environment

With a complex, multiphysics environment, Live Parts™ accounts for compounding environmental and application forces — strengthening parts for both expected and unexpected conditions.

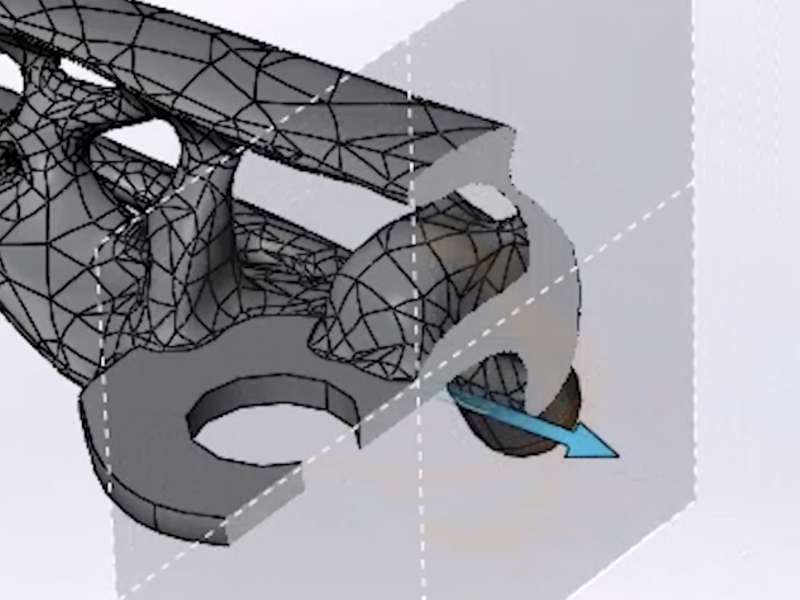

Live FEA Analysis

View FEA analysis throughout part generation to assess progress and performance. View how your part, in its designated material, will stand up to real-world conditions by toggling between von Mises stress and displacement in real time.

Easy Interactive Modelling

Live Parts™ allows users to take control of the modeling process. With the ability to adjust parameters on the fly, users can see designs change in real-time and easily export them to CAD software for refinement.

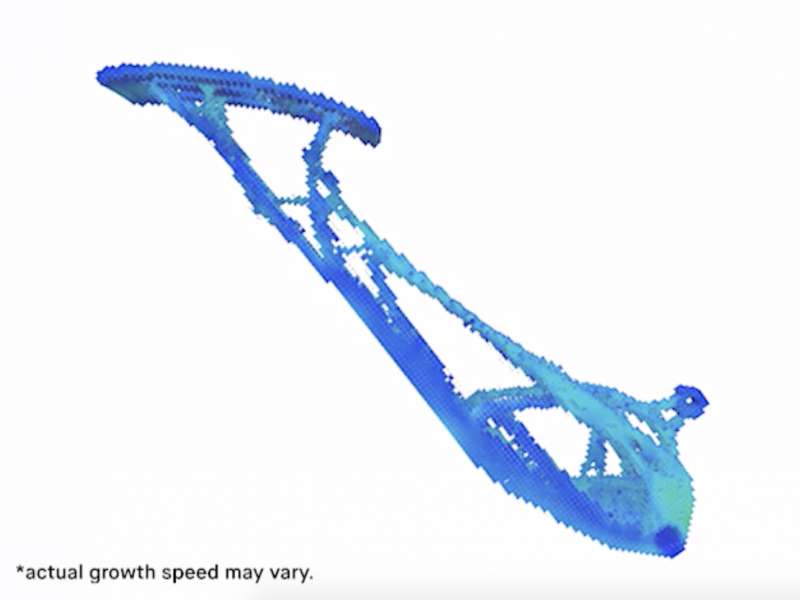

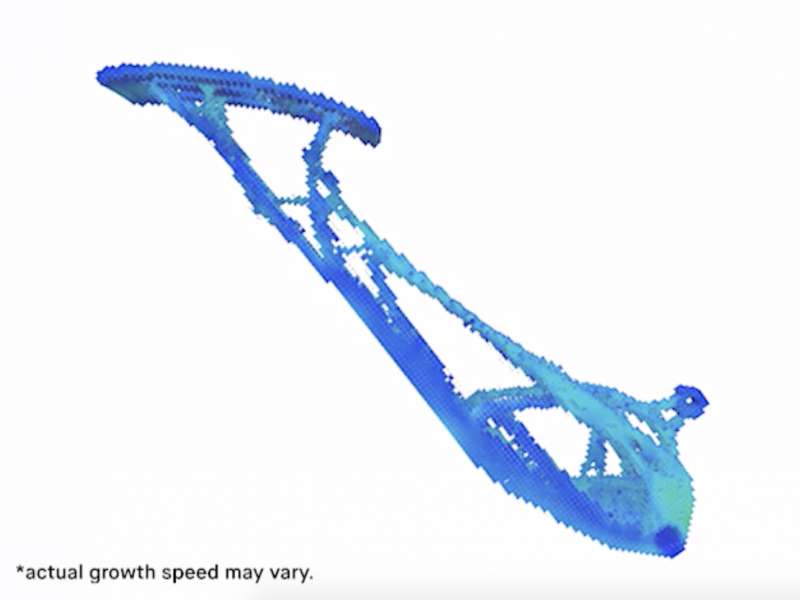

Real-Time Generation

Parts are generated in real time and respond to forces as they're applied, meaning users can quickly arrive at the best solution without waiting for a blackbox algorithm or analyzing multiple options for selection.

Live Adjustable Parameters

Adjust parameters - force, magnitude, material, direction - live and immediately see the impact of the changes in real-time throughout the build. Forces, material, support angles and more can be adjusted on the fly during growth.

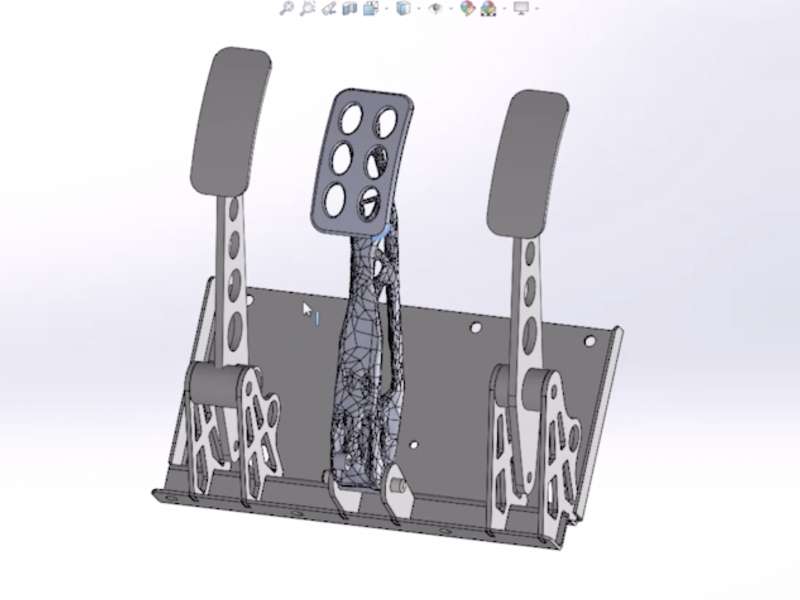

Seamless CAD integration

Live Parts™ enables direct export to Solidworks and other CAD software for assembly and further finite element analysis (FEA) and modeling. Designs can easily be moved between CAD software and Live Parts™, simplifying iteration without repeating setup processes.

Manufacturing-ready parts

With Live Parts™ there’s no need to spend additional time refining generative designs for manufacturing. Simply define your constraints and the software does the rest, resulting in manufacturing optimized models that are ready to build.

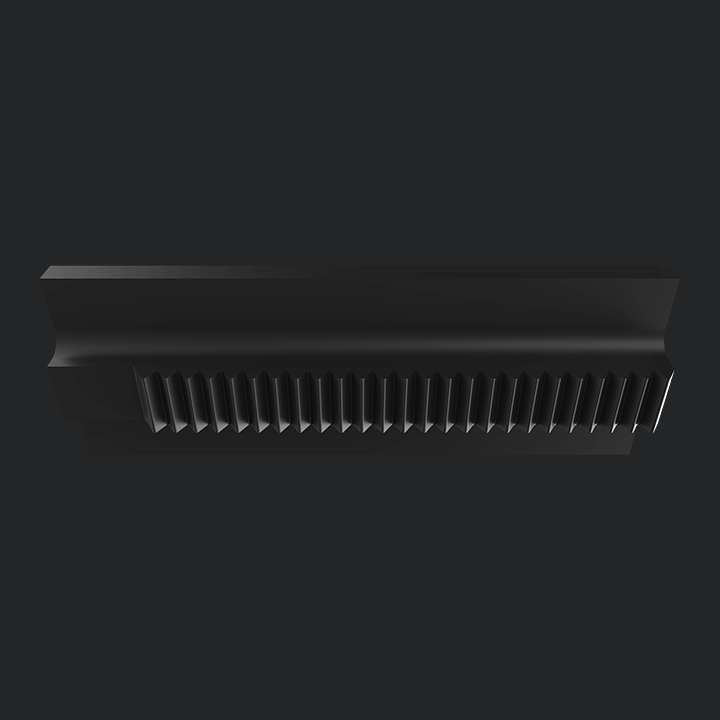

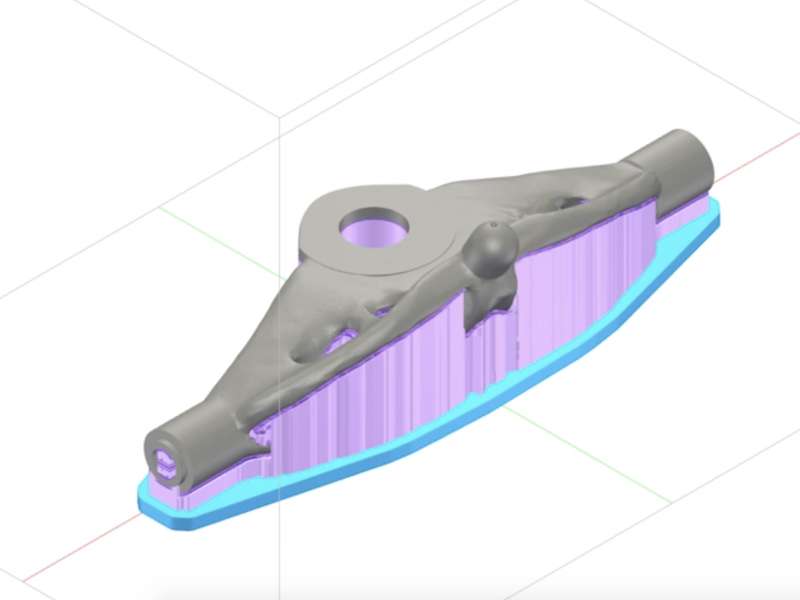

Additive design constraints

With the ability to set constraints on build direction, supports, and more, designs generated by Live Parts™ can be optimized for 3D printing success.

Automatic smoothing

Part geometry is automatically smoothed — creating clean files and avoiding issues of concentrated stresses, resulting in geometry ready for manufacture.

Manufacturing-optimized

Export files in the format needed for your manufacturing method - whether additive or subtractive - including water-tight STLs and solid-body models. Or import back into CAD for further refinement and featuring.

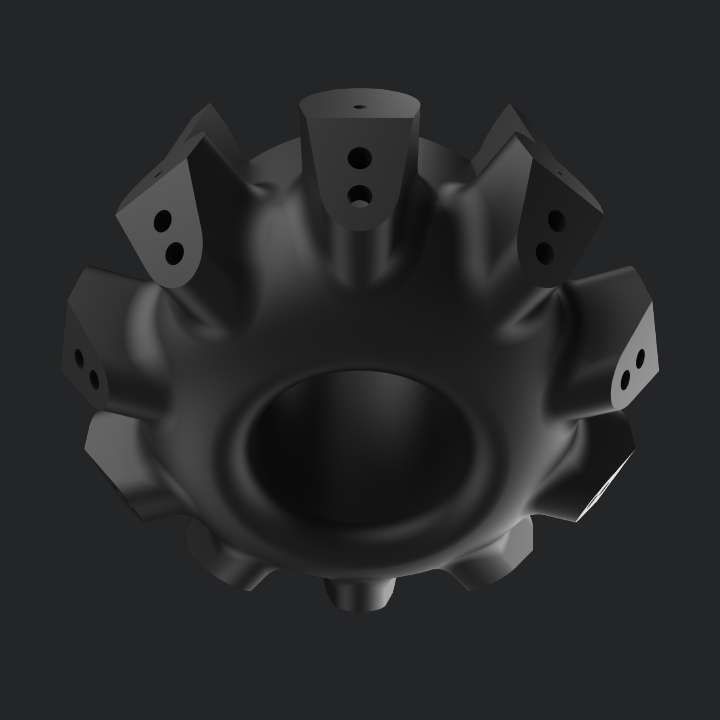

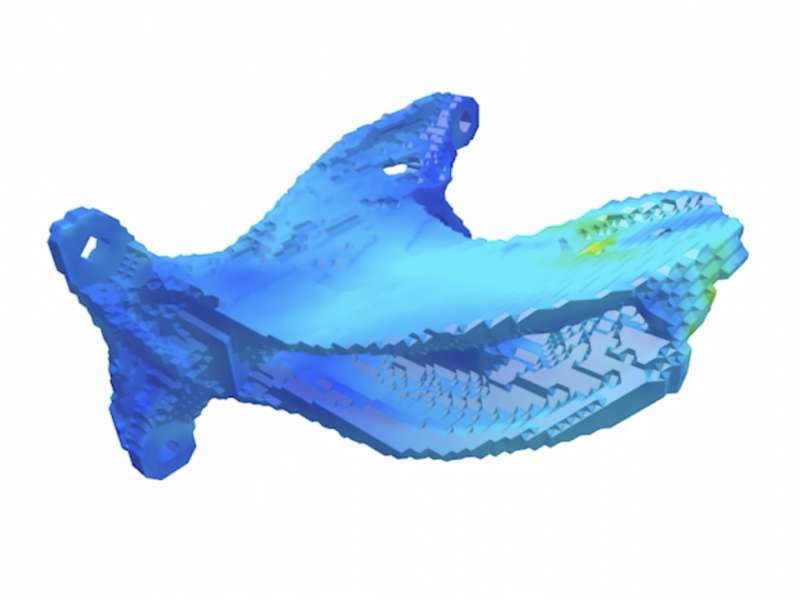

Part gallery

Live Parts™ applications span a variety of industries including manufacturing, tooling, automotive, consumer, electronics, and oil & gas.

Applications by Industry

Explore applications for 3D printing across a range of industries.