Webinars

-

-

How combining metal binder jetting and CNC machining is reshaping industrial production

Learn how hybrid production with the Desktop Metal Shop System is revolutionizing industrial workflows, reducing lead times, and enabling the creation of complex, high-performance components in this on-demand webinar.

-

Binder Jet Metal 3D Printing End-to-End Webinar Series

Take a deeper technical dive into the binder jetting workflow with our exclusive webinar series covering the entire workflow.

-

From Setup to Success – Meet the world’s most researched binder jetting machine

Watch this on-demand webinar that will help you understand how you can leverage the power of binder jet 3D printing technology with the research-friendly InnoventX. In this in-depth session, we guide you through the entire process of setting up a build, from the software workflow and machine preparation to parameter adjustments and sintering.

-

-

-

How easy is it really? Take a walkthrough of adopting office-safe metal 3D printing

Join our team of experts for a walkthrough of the metal 3D printing process while reviewing operational information like safety procedures and waste requirements to gain a better understanding of how easy 3D printing a variety of metals can be.

-

Elevating Additive and Traditional Manufacturing With Advanced High-Purity Sintering

Discover how the newly launched PureSinter™ Furnace from Desktop Metal can help improve the sintering process, reduce operational costs, enhance production quality, and offer long-term reliability—all with easier implementation and lower maintenance demands.

-

Metal 3D Printing for the Food Processing Industry with Elliði Hreinsson, Founder of Curio

Curio fish processing systems are transformed with stainless steel parts 3D printed on the Desktop Metal Studio System. Join us for a conversation with Elliði Hreinsson, Founder of Curio, to hear about his experience designing food equipment with 3D printing – from plastic mockups to rapid prototyping and batch production in 316L with office-friendly Bound Metal Deposition technology.

-

-

-

How to Implement 3D Printing for Production: Azoth3D Shares Their Experience

Azoth believes metal binder jet technology is the ideal 3D printing method for manufacturing small, complex metal components and helps manufacturers create efficient digital inventories through its Take One Make One (TOMO) strategy. Its team helps manufacturers plan for a component's lifecycle and find where 3D printing qualified parts on-demand makes sense—from prototype and production to replacement and legacy part strategies.

-

How to Earn Additive Manufacturing Qualification in the Energy Industry

Are you interested in learning about the certification process for additive-manufactured metallic parts used in energy, oil & gas, and maritime applications? In this webinar we explore the DNV-ST-B203 standard and the prestigious AM manufacturer certificate received by Aidro for the binder jetting technology developed by Desktop Metal. AM, also known as 3D printing, is revolutionizing the way components and parts are produced across various industries, and the energy sector holds great potential for usage. To fully unlock the potential of AM in the energy industry, stringent qualification processes are necessary to guarantee the safety and reliability of critical components.

-

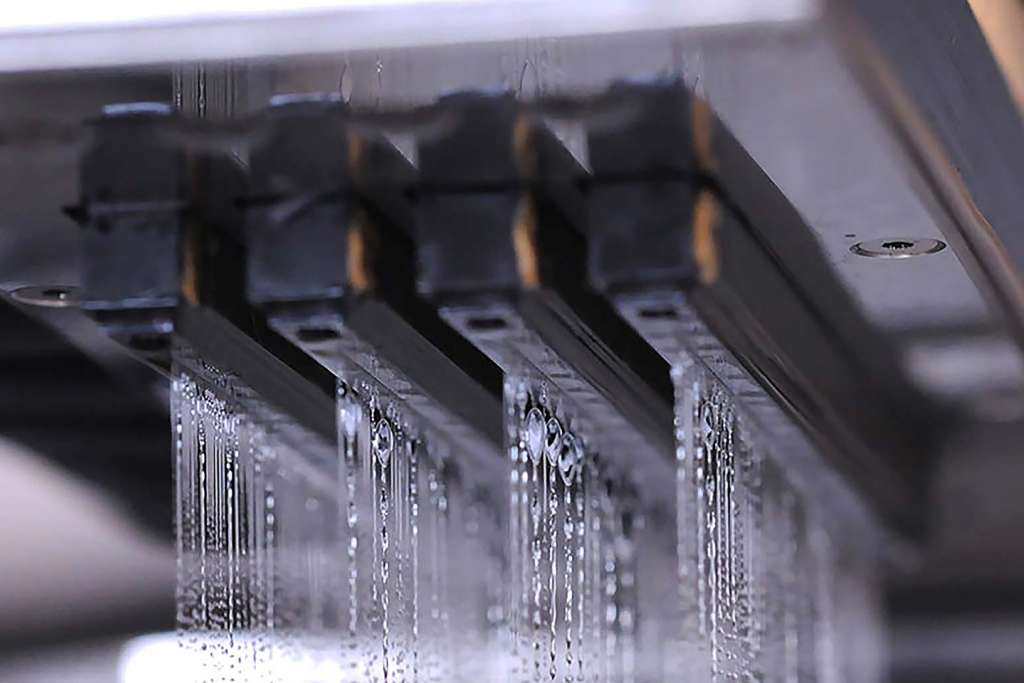

Breaking Down AM Binder Selection for Various Applications

Binder plays a critical role in additive manufacturing— but not all binders are created equal! Environmental regulation, material compatibility, post-print strength, and end part purity are just a handful of considerations when optimizing processes for your application. In this webinar, Eric Rhodes, Materials Engineer, will discuss Desktop Metal’s portfolio of binders for metal and ceramic powders, why they are critical to binder jetting technology, and how they differentiate within the additive manufacturing industry.

-

-

-

Cost-Effective Metal Part Production: Metal 3D Printing Cost Comparison

Metal 3D printing is no longer a novel technology, yet how it compares to traditional manufacturing processes—especially on cost—can still be an ambiguous equation. It has a reputation for being expensive, but it that a true apples-to-apples comparison? And how does the equation change if metal 3D printing is being evaluated as a complementary (instead of competitive) method? During this webinar, FreeFORM Technologies and Desktop Metal will explore how metal 3D printing compares to traditional manufacturing methods through a detailed comparison of metal injection molding and metal binder jetting.

-

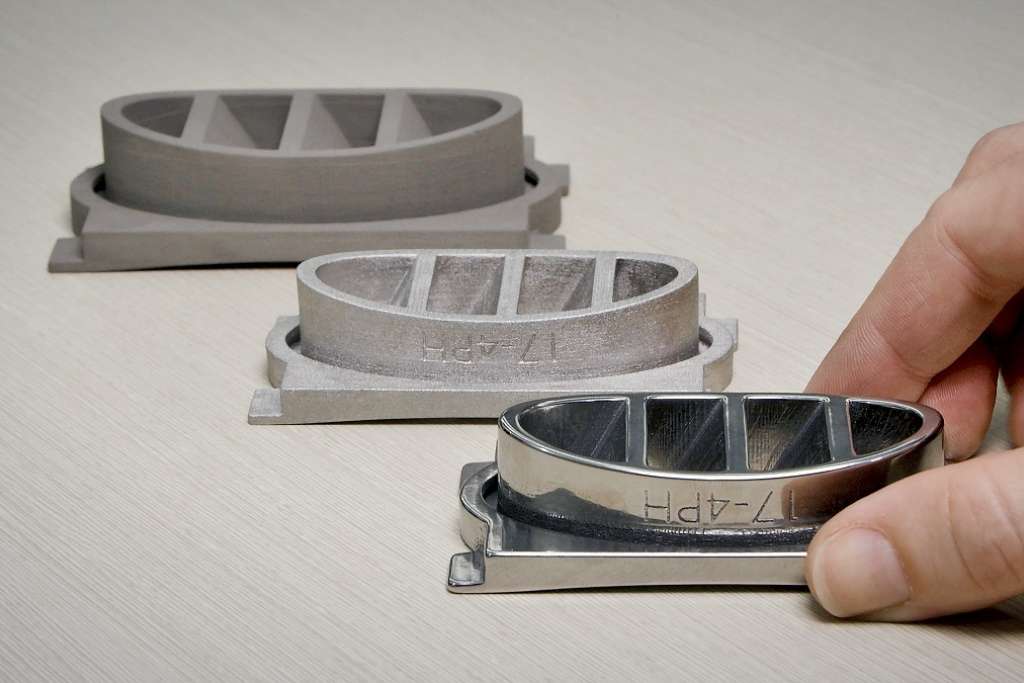

Easy-Adopt Metal 3D Printing: Which technology is right for you?

Metal 3D printing can be transformational - unlocking new design freedoms for part innovation with fast iterations and enabling tooling-free production of spare parts or custom fixtures. When getting started with the technology, it’s important to understand the different technologies available to make sure your investment fits your production workflow and your company gets the best ROI.

-

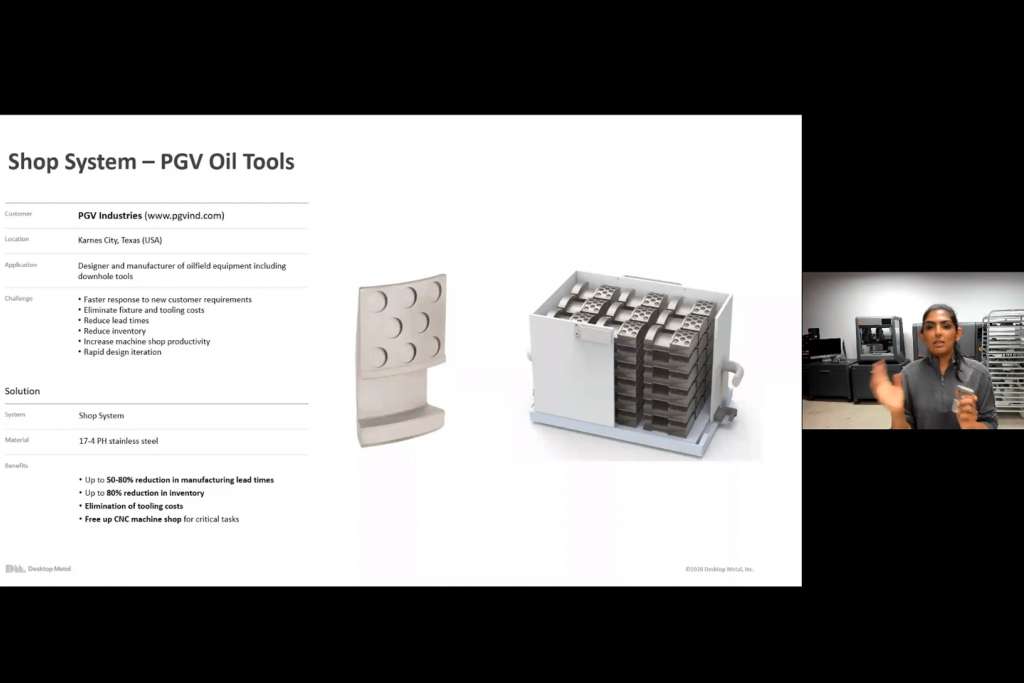

Metal 3D Printing for Machine Shops: Success Stories from the Field

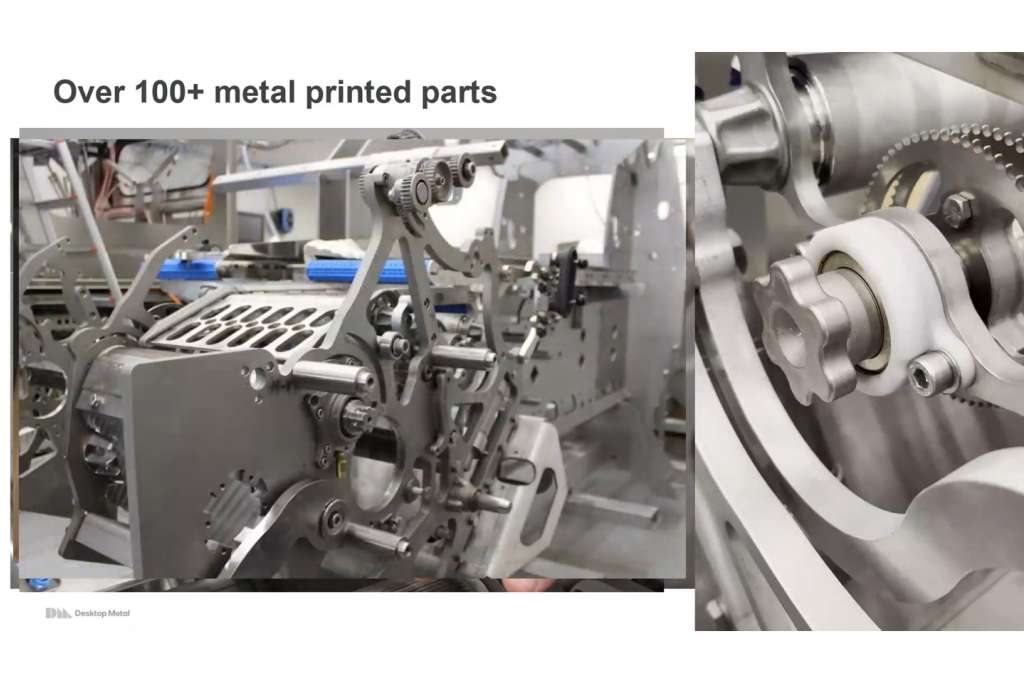

Binder jet metal 3D printing has become more widely adopted by machine shops across the globe. This technology provides many benefits to shop owners and operators, including increased productivity, faster lead times, affordable per-part costs and reduced time/labor. Binder jetting has become a key technology to bring metal additive manufacturing to mass production. Desktop Metal's Shop System is designed to bring metal 3D printing to machine shops.

-

-

-

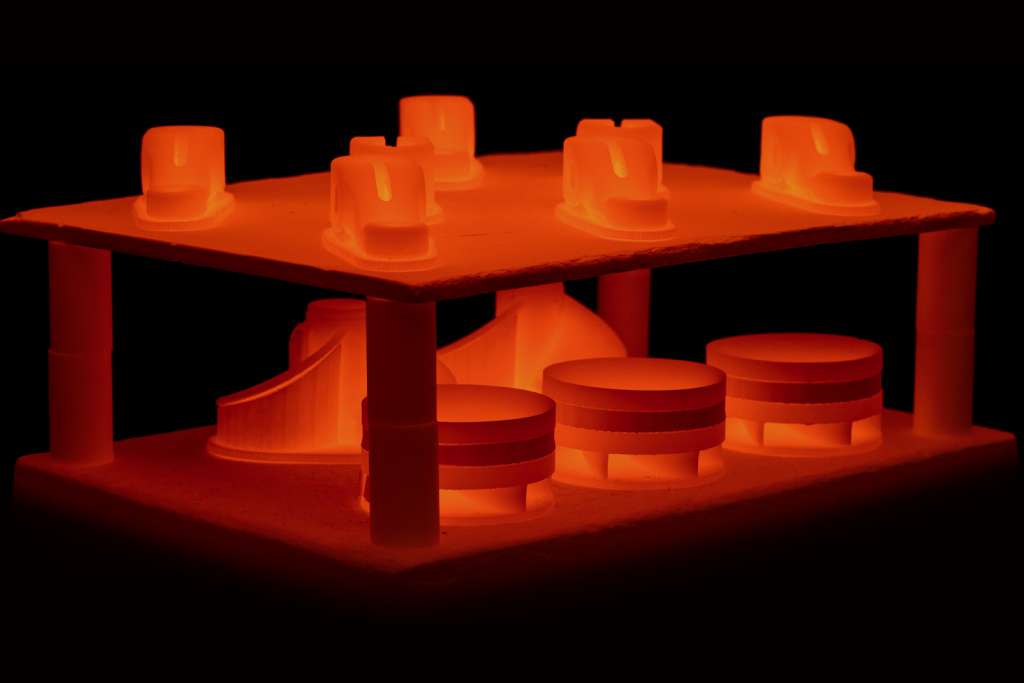

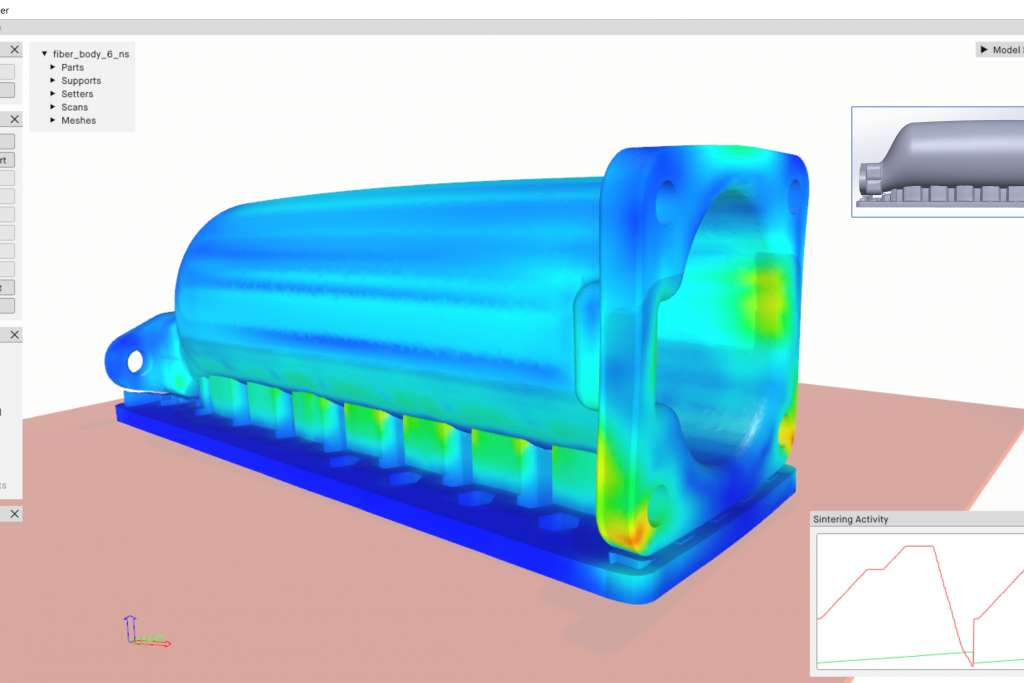

Manufacturing Preparation Software for Successful Sintering of Binder Jet 3D-Printed Metal Parts (2022)

Desktop Metal’s Live Sinter™ is a manufacturing preparation software for the successful production of powder metal sintered parts. During this webinar, learn more about the causes of sintering distortion and how Live Sinter simulates part behavior, including shrinkage and distortion, to help Desktop Metal customers 3D print and sinter metal parts successfully.

-

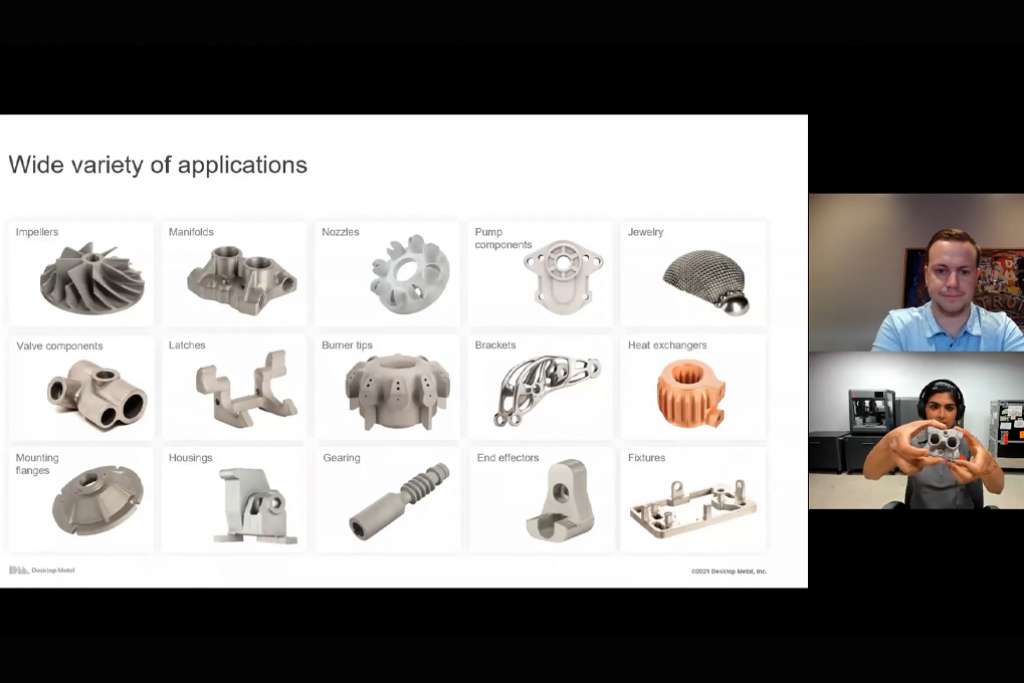

Metal 3D Printing for Machine Shops and Service Bureaus

Mass production metal 3D printing solutions offer service bureaus and machine shops an opportunity to service a broader set of customers with an expanded array of applications, ranging from one-offs to batch (or even mass) production of metal parts. Benefits such as assembly consolidation and geometric freedom allows service bureaus to extend the benefits of metal 3D printing to their customers.

-

How Your Business Can Outperform the Competition During the Supply Chain and Labor Crisis with 3D Printing

During this webinar, Desktop Metal assembles both company and industry experts to share up-to-date forecasts on how long the supply chain and labor crisis will last and show how machine shops and other manufacturers are carving out an advantage during this time with agile, turnkey digital manufacturing tools.

-