Our Metal 3D Printers

Office-friendly production of metal prototypes and one-off parts. Just Print. And Sinter.

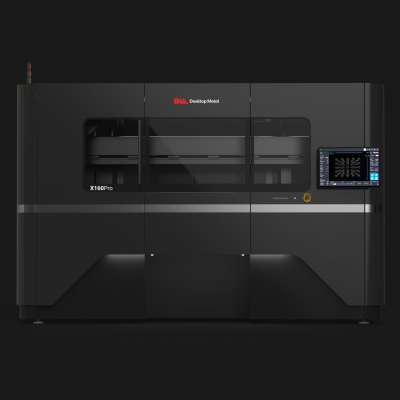

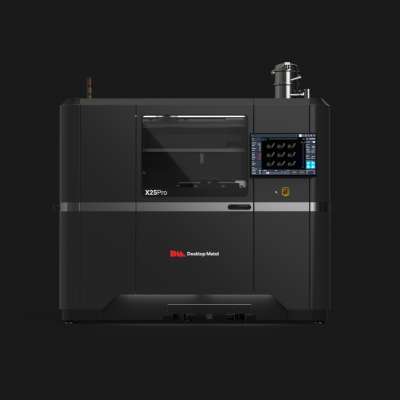

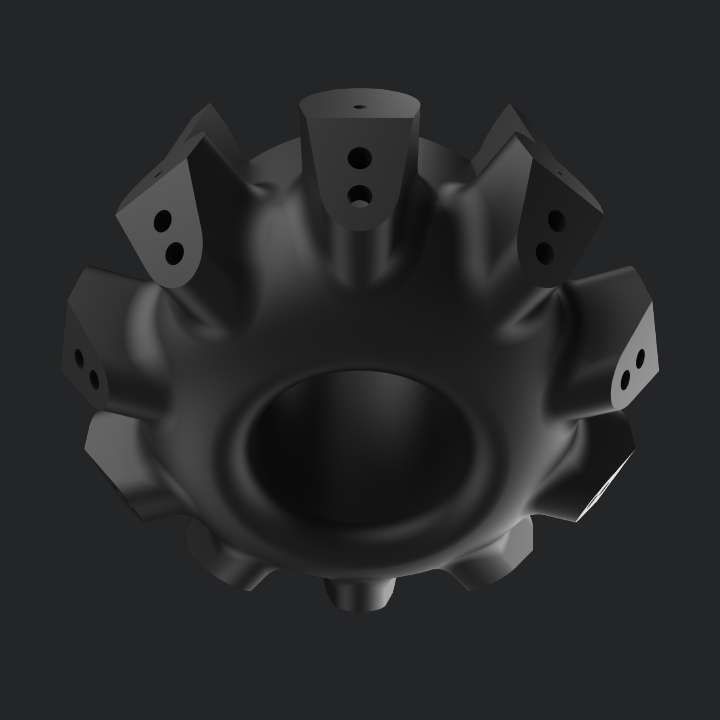

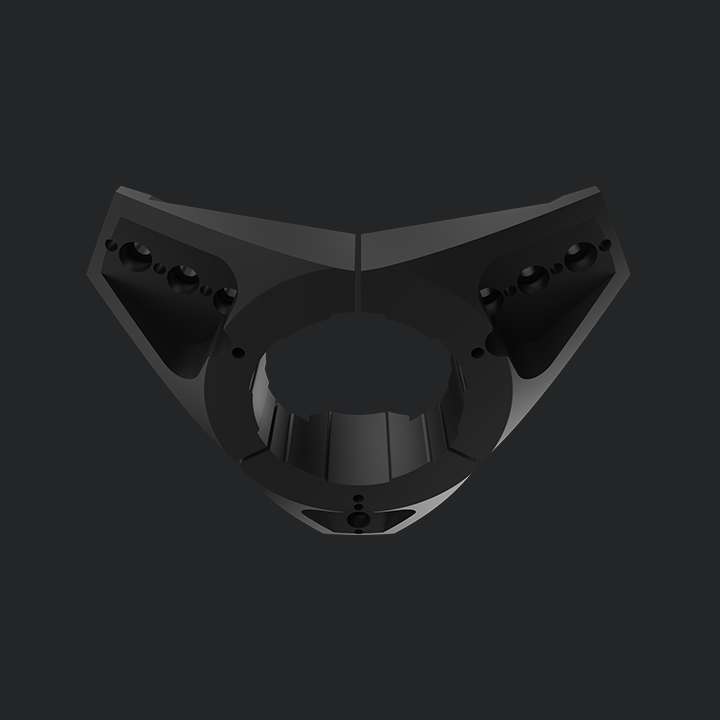

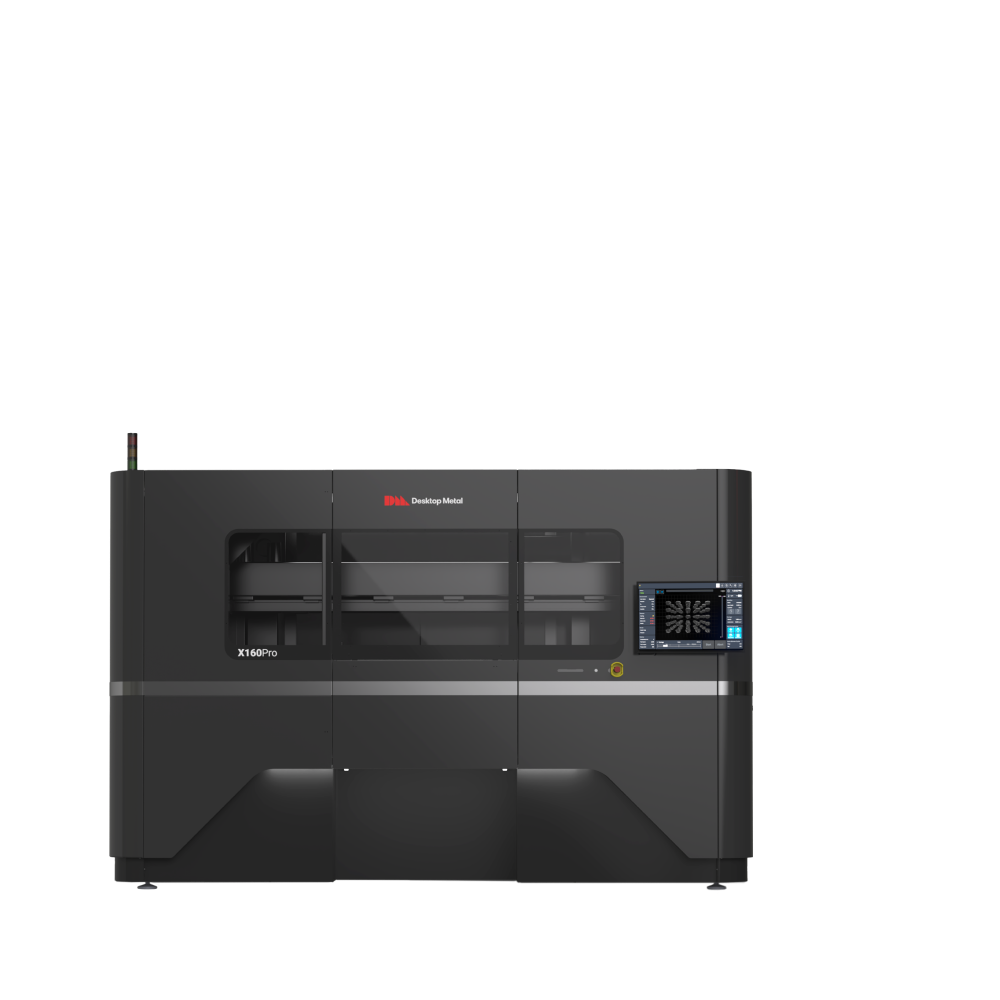

Binder jet 3D printing of metals or ceramics, featuring patented Triple ACT. Three models offered: the InnoventX, the X25Pro and the X160Pro.

High-speed mass production of metal parts with patent-pending Single Pass Jetting (SPJ) technology. Two models offered: the P-1 and P-50.

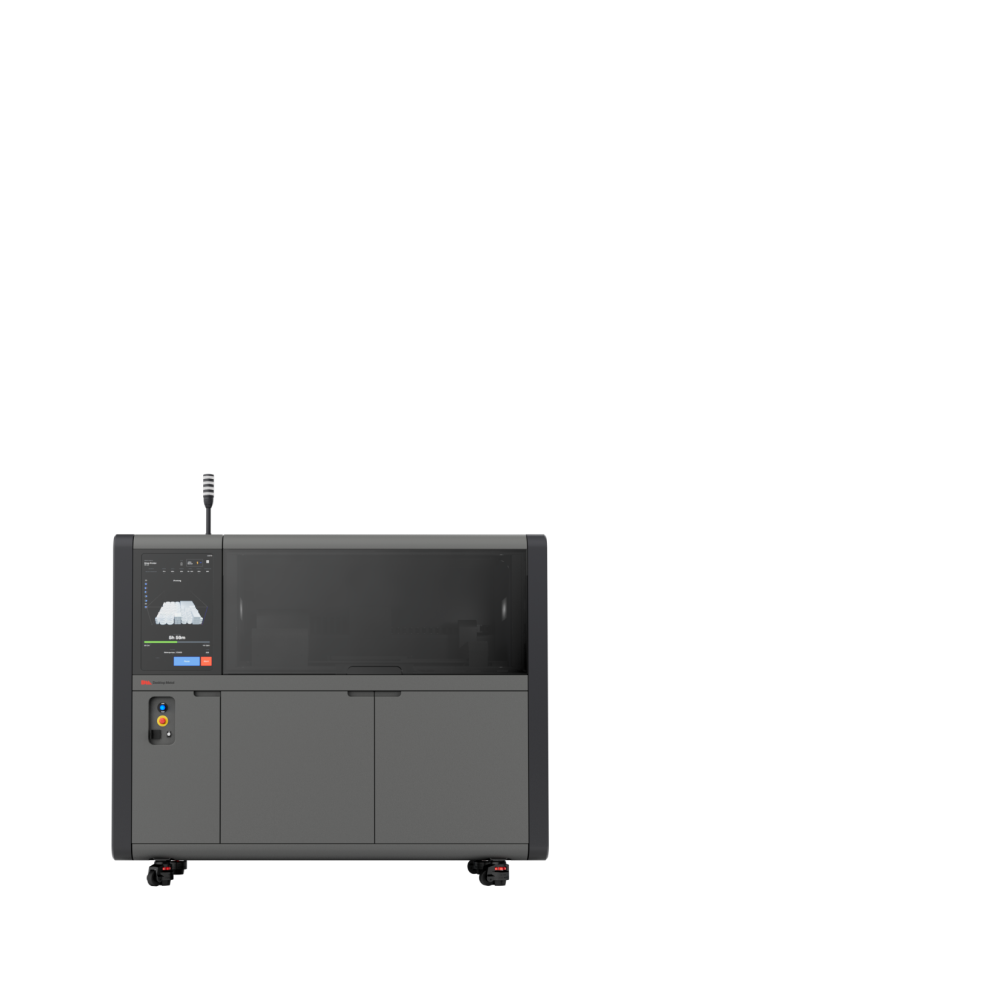

Bound Metal Deposition (BMD)

Binder Jetting

Binder Jetting, with Triple Advanced Compaction Technology

Binder Jetting, with bidirectional Single Pass Jetting(SPJ) Technology

300 x 200 x 200 mm

16L — 350 x 220 x 200 mm

12L — 350 x 220 x 150 mm

8L — 350 x 220 x 100 mm

4L — 350 x 220 x 50 mm

800 x 500 x 400 mm — X160Pro

400 x 250 x 250 mm — X25Pro

160 x 65 x 65 mm — InnoventX

490 x 380 x 260 mm— P-50

200 x 100 x 40 mm — P-1

800 cc/hr

3,120 cc/hr — X160Pro

1,200 cc /hr — X25Pro

54 cc/hr — InnoventX

12,000 cc /hr — P-50

1,350 cc/hr — P-1

0.40 mm nozzle diameter, standard resolution

0.25 mm nozzle diameter, high resolution

1600 dpi (1 PL native drop size)

> 30 µm voxels for all models, based on using a 10 picoliter printhead and 30 μm layer. Results may vary based on materials and other factors.

Native 1,200 dpi

50–150 μm in green state, high resolution printhead

150–300 μm in green state, standard resolution printhead

50 μm – 100 μm

30 μm – 200 μm

30 μm – 200 μm

Download our guide for an in-depth comparisons between the Shop System and Studio System metal 3D printers. Learn the key differences between our two plug-and-play options to get started with metal 3D printing today.

DownloadAdditive Manufacturing 2.0

Our customers are among the most innovative companies in the world. They’re using our 3D printing technology to usher in the next era of Additive Manufacturing 2.0 for production 3D printing.

Applications by industry

Our customers are among the most innovative companies in the world, and are using Desktop Metal 3D printing technology to reinvent how metal parts are created across a diverse range of industries.