Case Studies

-

-

FreeFORM Technologies: New levels of creativity and design to customers through the use of additive manufacturing

FreeFORM Technologies, one of the first service bureaus to offer metal binder jet additive manufacturing, is bringing new levels of creativity and design to customers through the use of additive manufacturing.

-

TECNALIA Research & Innovation: Silicon carbide satellite optical mirror supports printed on the X-Series

The team at TECNALIA is sending optimized silicon carbide into space with binder jetting.

-

Ultra Safe Nuclear Corporation: 3D printing silicon carbide to support next-generation nuclear fuel

Ultra Safe Nuclear Corporation 3D prints silicon carbide heat-resistant ceramic particles in unique geometries that can safely surround nuclear fuel. Its innovation is enabled by binder jetting the technical ceramic on Desktop Metal X-Series binder jet systems.

-

-

-

EAC: Custom metal jewelry and ornaments for luxury goods

Learn how EAC, a worldwide leader in the production of metal accessories for luxury goods, is using the Desktop Metal Shop System to manufacture custom metal hardware for everything from leather goods to lingerie to jewelry.

-

Saint Gobain Research North America: 3D printing technical ceramics at scale

Saint-Gobain Research North America uses Two X-Series Binder Jetting Systems to Research, Develop, and Scale Technical Ceramic and Silicon Carbide 3D Printing

-

TECNALIA Research & Innovation: Binder jetting tool steels and hard metals for cutting tools

TECNALIA Research & Innovation uses its material and manufacturing expertise to develop innovative designs for M2 and WC-Co cutting tools.

-

-

-

JJ X-Ray: Enriched boron carbide ceramic collimator advances neutron research

Researchers at JJ X-Ray to advance 2D collimation with the design freedom of Desktop Metal binder jet technology to 3D print technical ceramics on X-Series printer.

-

IDPro: Advanced manufacturing in the classroom

Based at the Lycée Polyvalent Aragon Picasso secondary school in Givors, France, PFT IDPro was founded in 2010 to help students and teachers develop advanced manufacturing skills

-

Ecrimesa: Staying on the cutting edge of innovation for a MIM and investment casting manufacturer

Founded in 1964, Ecrimesa Group produces steel and aluminium with cutting-edge technologies: investment casting, MIM, machining and additive manufacturing.

-

-

-

Egar Tool and Die: Stamping dies and tooling for the manufacturing floor

A leader in the production of automotive stamping dies, production stampings and welded assemblies for the automotive industry, Egar Tool and Die turned to the Studio System to meet customer demands, and to retool its own manufacturing lines quickly.

-

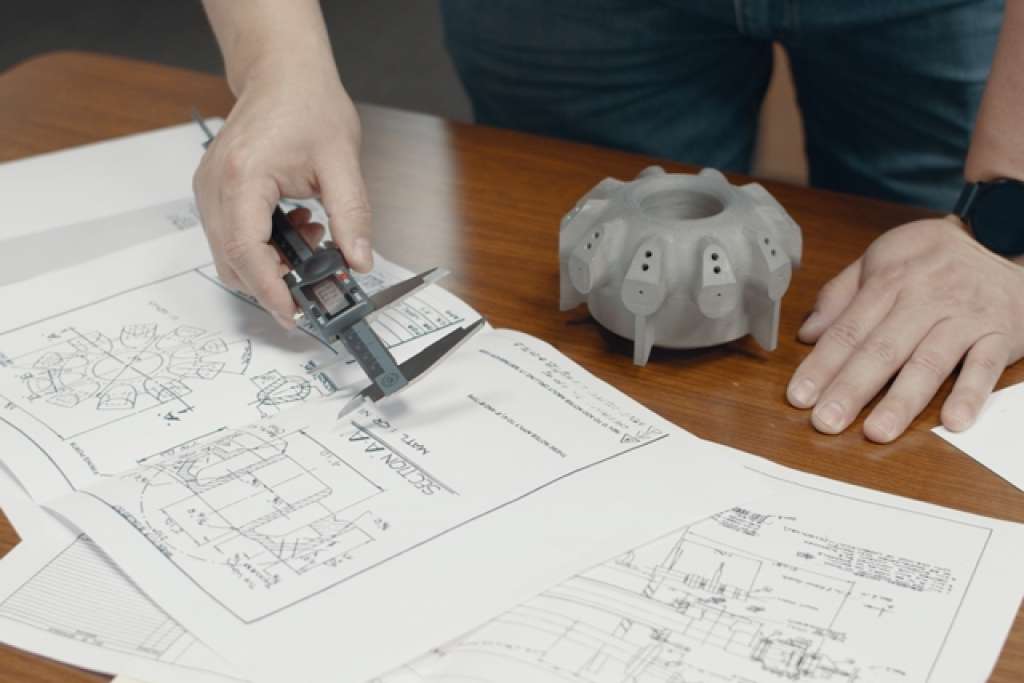

Alpha Precision Group uses metal 3D printing on the Studio System to cut lead times

Learn how APG has used their Studio System to produce a wide variety of parts including jigs, fixtures and end of arm tooling to help their manufacturing floor operate at full efficiency.

-

PGV: Using the Shop System to Revolutionize Supply Chains

Using the Desktop Metal Shop System, PGV is revolutionizing their supply chains by moving parts from traditional manufacturing processes like CNC machining to the Desktop Metal Shop System.

-

-

-

John Zink Hamworthy: Uses the Studio System to rapidly create prototypes, design and test innovative new part designs, and streamline workflows.

By eliminating the need for hard tooling, the Studio System makes it easy for John Zink Hamworthy Combustion engineers to produce innovative new parts, reproduce parts for which tooling no longer exists and find creative solutions to improving their workflow.

-

Innovative Plastics: Better injection molds with metal 3D printing

Using the Studio System, Innovative Plastics created mold cavities and cores in far less time - and at significantly less cost - than traditional methods.

-

Ford Motor Company: Additive to stay on the edge of innovation

Learn how Ford is using advanced 3D printing technologies like the Studio System to help drive the automotive factory of the future.

-