We are Team DM. We exist to deliver Additive Manufacturing AM 2.0 technologies, materials, and applications that enable mass production.

Platforms

_Case Studies

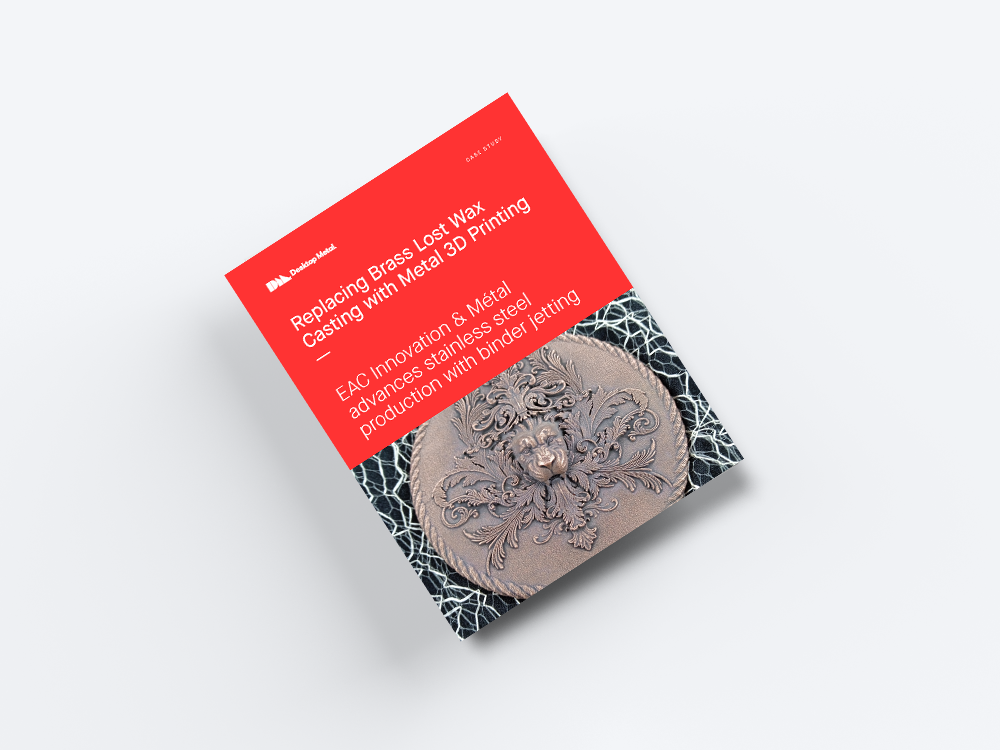

EAC Innovation & Métal replaces brass lost wax casting with stainless steel 3D printing