Case Studies

-

-

Ultra Machining Company: Developing a 21st century factory with 3D printing

Learn how one Desktop Metal customer sees the Studio System as an integral component to the factory of the future.

-

Jade Group: 3D Printing custom fashion accessories

A supplier of metal parts to many leading luxury brands, Jade Group uses the Studio System to create prototypes and iterate on part designs before they go into production. The company has also invested in the Shop System to produce larger volumes of parts.

-

University of Maine: Advocating for Advanced Manufacturing

The University of Maine is using the Studio System to train students in the use of advanced manufacturing, including metal 3D printing, and is working to help industry partners realize the benefits of additive manufacturing across a host of industries in the state.

-

-

-

Lumenium: Rapid prototyping with 3D printing

Learn how the ability to iterate metal parts quickly with the Studio System had a direct impact on time-to-market and overall performance for the Virginia based startup.

-

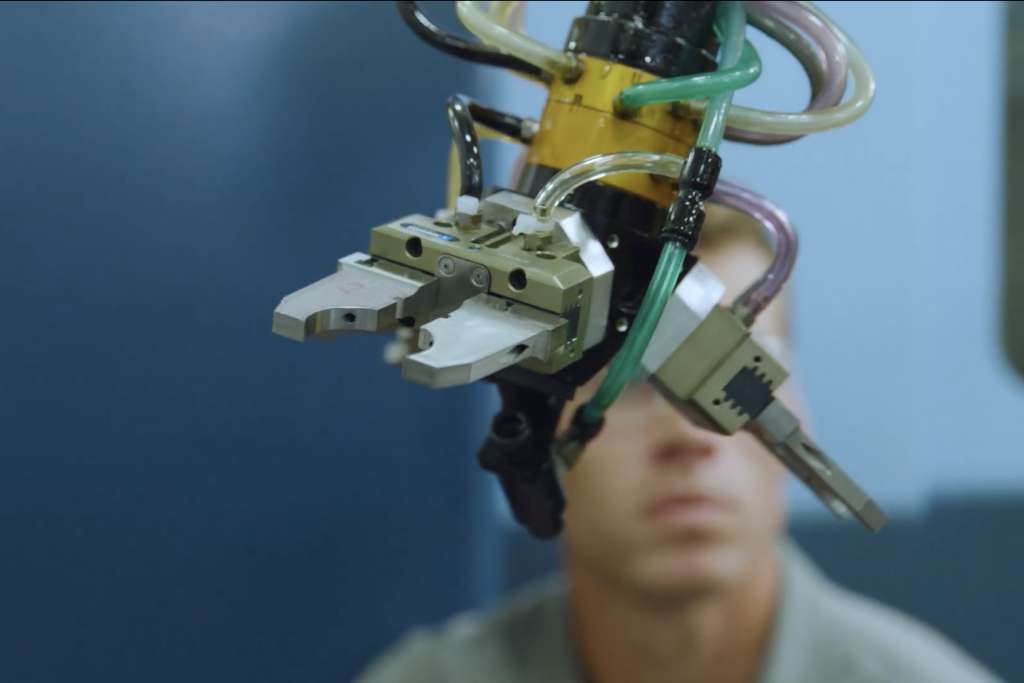

Battlebots® team builds combat robot with Studio System™ parts

The saw-wielding, flame-throwing robot uses Studio System parts that can withstand the demanding environment of the battle arena and adhere to the competition's strict build timeline.

-

Built-Rite: 3D printed injection molds

For an injection mold making firm, the Studio System enables the fabrication of quick-turn mold assembly components with a process that is far less labor-intensive than other equipment in the machine shop and more cost-competitive than a third-party prototyping firm.

-