Resources

-

-

Ultimate Guide to DLP

This comprehensive guide provides a technical overview of DLP printing, along with the latest information on innovations in machine design, from bottom-up to top-down printing — as well as new types of photopolymer resins that deliver durable, elastomeric material properties, including closed-cell foams.

-

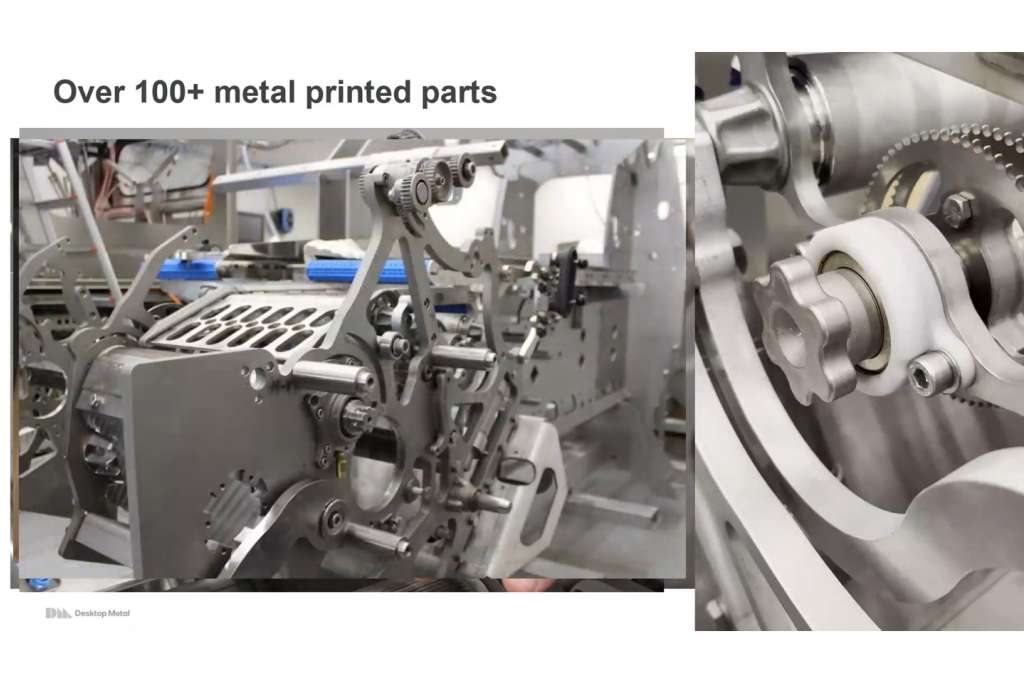

Functional prototyping using metal 3D printing

Functional prototypes are critical to development of a product or part - allowing engineers to test new ideas and designs while also revealing how a product will stand up to real-world use.

-

Manufacturing the Cars of Tomorrow

With the ability to make parts faster, cheaper and more complex than ever before - this is how the cars of tomorrow will be manufactured.

-

-

-

Studio System Design Guide

To leverage the advantages of additive manufacturing, it is important to optimize your design for the BMD process— printing, debinding, and sintering. Learn the best practices with this downloadable BMD Design Guide.

-

Understanding metal finishing methods for 3D printed parts

Desktop Metal partnered with Fortune Metal Finishing (FMF) to test several finishing methods on metal parts printed with the Studio System. This study focuses on three finishing technologies: centrifugal disc, centrifugal barrel, and media blasting.

-

The Studio System Part Gallery Catalog

This catalog contains over 50 metal 3D printed part examples with real-use case descriptions from Studio System customers, printed in a range of materials. Examples are complete with use-case details, benefits, cost savings vs traditional manufacturing, and part specifications.

-

-

-

The Shop System Part Gallery Catalog

This catalog contains over 30 metal 3D printed part examples with real-use case descriptions from Shop System customers, printed in a range of materials. Examples are complete with use-case details, benefits, cost savings vs traditional manufacturing, and part specifications.

-

Alpha Precision Group: 3D printing on a MIM manufacturing floor

Additive manufacturing allows APG engineers to significantly speed up the design, manufacture and deployment of custom jigs, fixtures and tooling, allowing them to save money on tooling and deliver parts to customers faster.

-

John Zink Hamworthy: Printing complex burner tips and on-demand shop floor tools

By eliminating the need for hard tooling, the Studio System makes it easy for John Zink Hamworthy Combustion engineers to produce innovative new parts, reproduce parts for which tooling no longer exists and find creative solutions to improving their workflow.

-

-

-

How easy is it really? Take a walkthrough of adopting office-safe metal 3D printing

Join our team of experts for a walkthrough of the metal 3D printing process while reviewing operational information like safety procedures and waste requirements to gain a better understanding of how easy 3D printing a variety of metals can be.

-

Elevating Additive and Traditional Manufacturing With Advanced High-Purity Sintering

Discover how the newly launched PureSinter™ Furnace from Desktop Metal can help improve the sintering process, reduce operational costs, enhance production quality, and offer long-term reliability—all with easier implementation and lower maintenance demands.

-

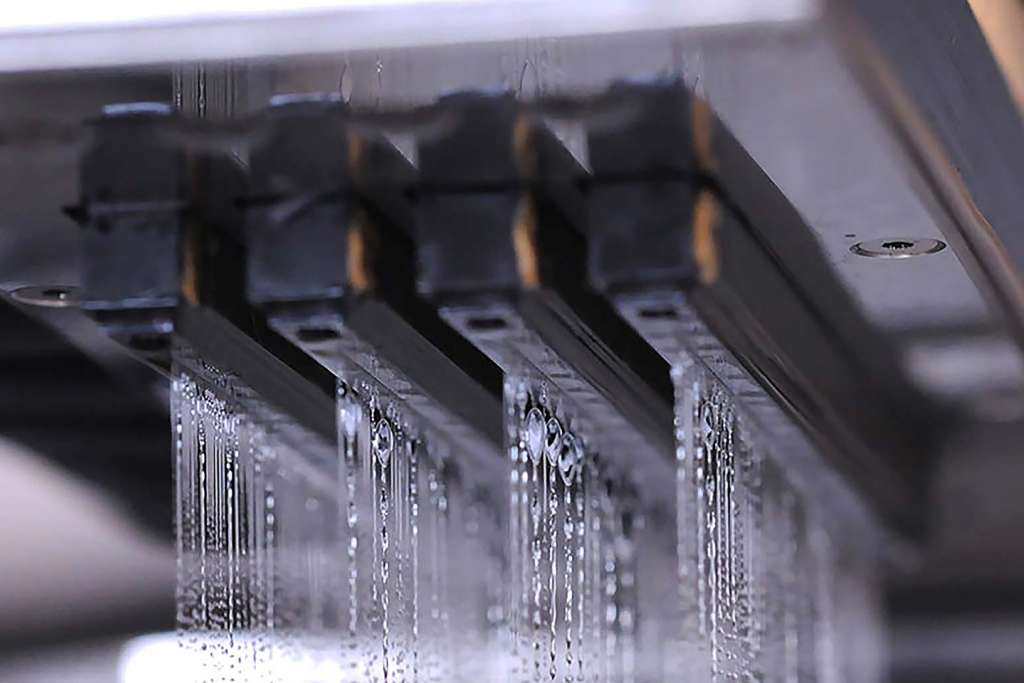

Metal 3D Printing for the Food Processing Industry with Elliði Hreinsson, Founder of Curio

Curio fish processing systems are transformed with stainless steel parts 3D printed on the Desktop Metal Studio System. Join us for a conversation with Elliði Hreinsson, Founder of Curio, to hear about his experience designing food equipment with 3D printing – from plastic mockups to rapid prototyping and batch production in 316L with office-friendly Bound Metal Deposition technology.

-

-

-

How to Implement 3D Printing for Production: Azoth3D Shares Their Experience

Azoth believes metal binder jet technology is the ideal 3D printing method for manufacturing small, complex metal components and helps manufacturers create efficient digital inventories through its Take One Make One (TOMO) strategy. Its team helps manufacturers plan for a component's lifecycle and find where 3D printing qualified parts on-demand makes sense—from prototype and production to replacement and legacy part strategies.

-

How to Earn Additive Manufacturing Qualification in the Energy Industry

Are you interested in learning about the certification process for additive-manufactured metallic parts used in energy, oil & gas, and maritime applications? In this webinar we explore the DNV-ST-B203 standard and the prestigious AM manufacturer certificate received by Aidro for the binder jetting technology developed by Desktop Metal. AM, also known as 3D printing, is revolutionizing the way components and parts are produced across various industries, and the energy sector holds great potential for usage. To fully unlock the potential of AM in the energy industry, stringent qualification processes are necessary to guarantee the safety and reliability of critical components.

-

Breaking Down AM Binder Selection for Various Applications

Binder plays a critical role in additive manufacturing— but not all binders are created equal! Environmental regulation, material compatibility, post-print strength, and end part purity are just a handful of considerations when optimizing processes for your application. In this webinar, Eric Rhodes, Materials Engineer, will discuss Desktop Metal’s portfolio of binders for metal and ceramic powders, why they are critical to binder jetting technology, and how they differentiate within the additive manufacturing industry.

-