How to Implement 3D Printing for Production: Azoth3D Shares Their Experience

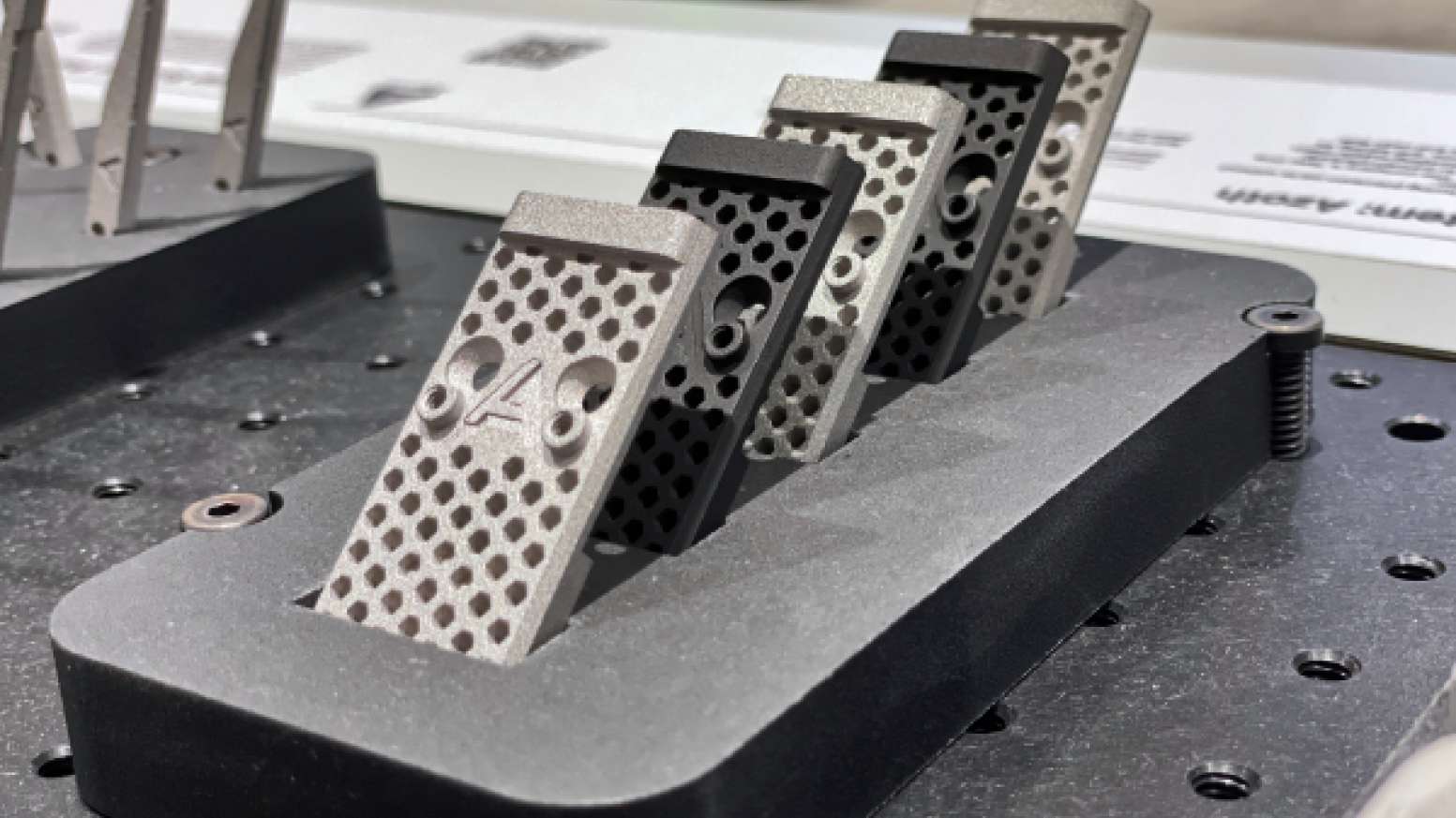

Azoth, a metal contract manufacturer in Michigan, has a team with experience rooted in sinter-based additive manufacturing. Azoth enables mass production of small complex parts throughout the automotive, defense, medical, and consumer goods industries and helps customers transition from alternative manufacturing methods like machining, investment casting, and metal injection molding (MIM) in order to implement the benefits of additive manufacturing.

Azoth believes metal binder jet technology is the ideal 3D printing method for manufacturing small, complex metal components and helps manufacturers create efficient digital inventories through its Take One Make One (TOMO) strategy. Its team helps manufacturers plan for a component's lifecycle and find where 3D printing qualified parts on-demand makes sense—from prototype and production to replacement and legacy part strategies.

During this webinar Azoth will share their experiences with implementing metal 3D printing while answering some common questions.