Resources

-

-

Easy material changes with the Studio System

In this video, Matt Barbati walks through how to change materials in the Studio System metal 3D printer.

-

Hot-swappable media cartridges

In this video, Matt Barbati discusses the cartridge design and how it supports a seamless workflow for in-house metal 3D printing.

-

Separable Supports™ for easy post-processing

In this video, Dave Belanger explains the advanced, auto-generated support structures designed to simplify post-processing for metal 3D printed parts.

-

-

-

Binder Jet Design Guide

Important design considerations for optimizing printing with binder jet

-

PureSinter™ Brochure

High Purity. High Efficiency. High Reliability. This all-new vacuum furnace for one-run debinding and sintering features breakthrough premium performance at an affordable price

-

Team DM Catalog

Easy-to-use Additive Manufacturing 2.0 solutions for industrial and healthcare production — delivering transformative value

-

-

-

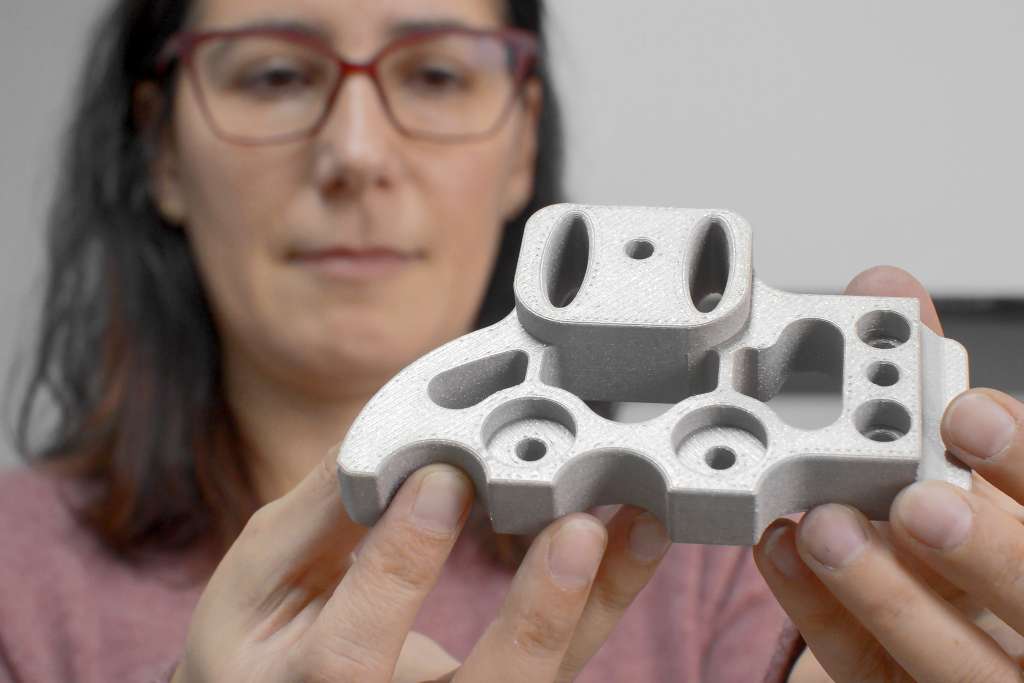

Team DM Master Material Guide

At Desktop Metal, we offer more than metals now. Our materials library spans virtually every category, from metals and polymers, to ceramics, composites, and even upcycled materials such as wood. In an effort to drive production 3D printing to the masses, our qualified materials are designed to ensure that you can 3D print with success and deliver the high-quality parts you need for end-use production.

-

Ceramic 3D Printing with Binder Jetting Guide

Forming technical ceramics the traditional way can be expensive, with long-lead time molds and expensive post-processing, such as precision cutting and grinding. Advanced, high-hardness ceramics often require an ultrahard diamond tool for precision finishing. With the flexibility of binder jetting, however, creating precision technical ceramics, which can be sintered or infiltrated to create ceramic composites, is relatively easy. Virtually any geometry, regardless of complexity, can be created — bringing the many benefits of technical ceramics to new forms and products.

-

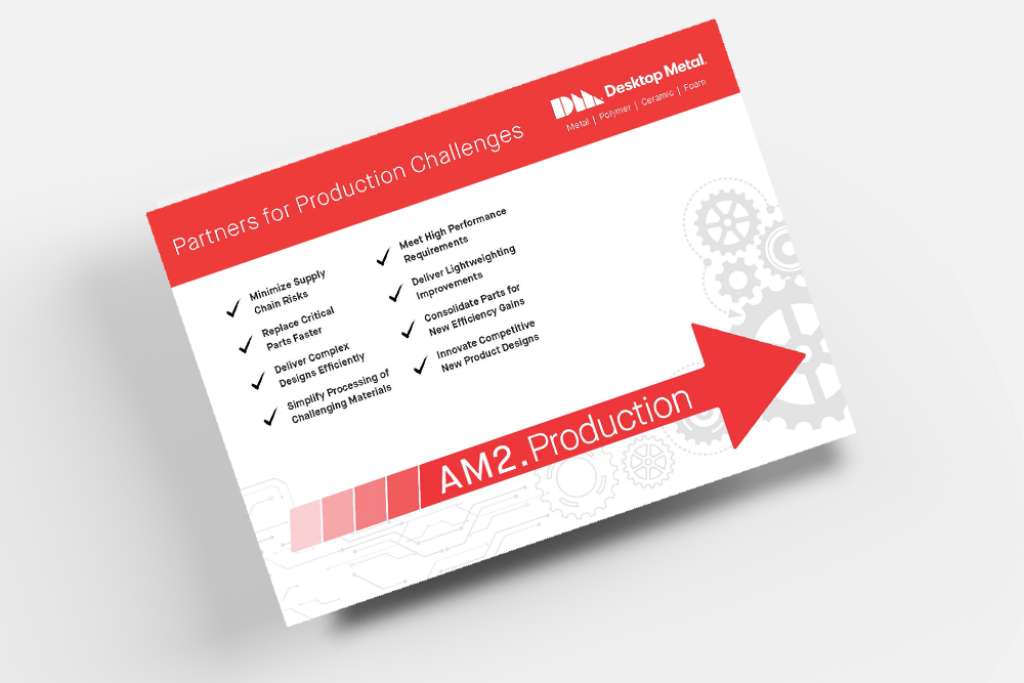

Partnerships for Additive Manufacturing Production Challenges

Custom programs developed to ensure success, both technically and economically, with our additive manufacturing technologies. Learn more about our seasoned team leaders and program options in this guide.

-

-

-

Figur G15 Brochure

Digital Sheet Forming: On-demand, flexible manufacturing without dies to revolutionize the way complex sheet metal parts are formed

-

The Ultimate Guide to Laser-Free Metal 3D Printing with Binder Jetting Technology

This 40-page guide is the most authoritative introduction to date on metal binder jetting — the most promising ASTM-recognized 3D printing technology for the mass production of metal parts and products. This guide contains a comprehensive overview of high-speed 3D printing of metals without a laser. Explore why binder jetting holds the keys to enabling the next era of Additive Manufacturing 2.0, which can unlock the innovation, agility and sustainability benefits of 3D printing in meaningful high volumes.

-

Five Steps to Evaluate Your Site for Metal 3D Printing

A quick guide for those looking to adopt metal 3D printing, with the steps you can take to compare various technologies and how they fit in your production environment.

-

-

-

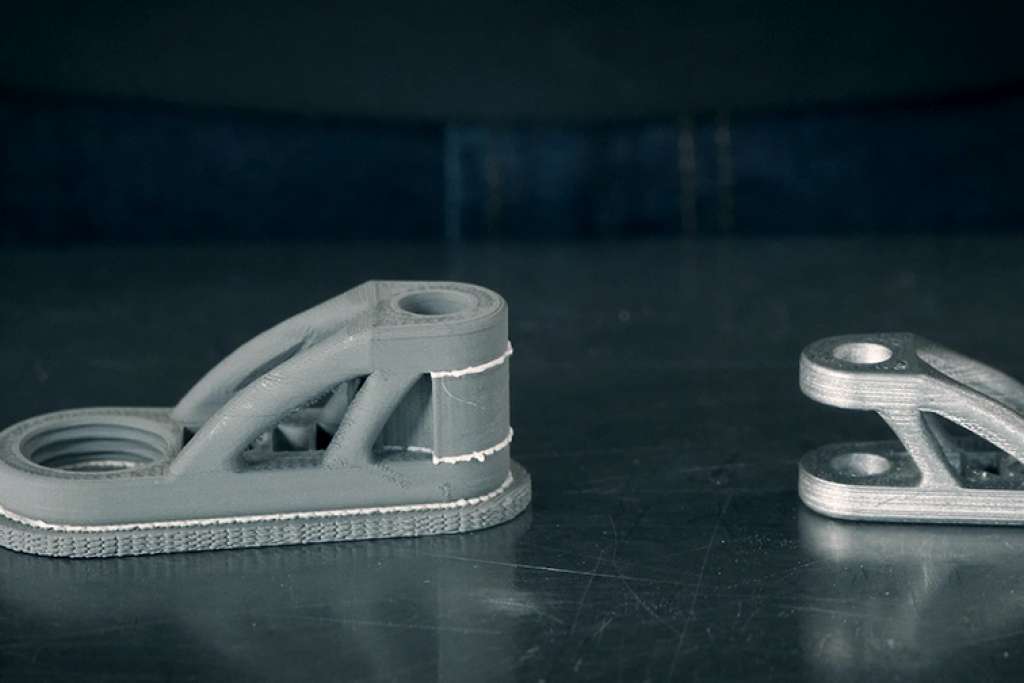

Easy-Adopt Metal 3D Printing System Overview: Shop System™ & Studio System™

Download our system overview to learn the key differences between of our two plug-and-play options to get started with metal 3D printing today.

-

System Overview: Easy-Adopt Metal 3D Printing For Education & Research

Download a system overview to learn the key differences between two easy-adopt options for educators to get started with metal 3D printing today

-

The Studio System™ Brochure

Office-Friendly Metal 3D Printing; Easy-to-adopt Bound Metal Deposition 3D printing for any office, studio, or lab

-