H13 Tool Steel

About H13 Tool Steel

Tool steel refers to a variety of carbon and alloy steels that are particularly well suited for toolmaking. Their suitability comes from their distinctive hardness, resistance to deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are well suited to shape other materials.

H13 is a chromium molybdenum hot work steel well known for its exceptional hot hardness and abrasion resistance, making it ideal for a variety of hot work applications. H13 can also be used in cold work applications thanks to its general hardness and toughness.

- Mold inserts

- Extrusion dies

- Forging dies

- Sheet metal tooling

- Stamping tools

BMD + H13

H13’s high hardness and toughness make it particularly difficult to machine, and often requires specialty holders, cutting tools, low feed rates and conditions. Due to these challenges, H13 parts can be both time consuming and expensive to fabricate. By applying the BMD process to H13, teams can quickly fabricate H13 tools—potentially featuring complex geometries that would otherwise be unachievable or prohibitively difficult through machining (e.g., molds with conformal cooling channels). This geometric freedom, combined with the cost-effective manufacturability provided by the Studio System, makes printing complex H13 parts particularly advantageous compared to traditional manufacturing methods.

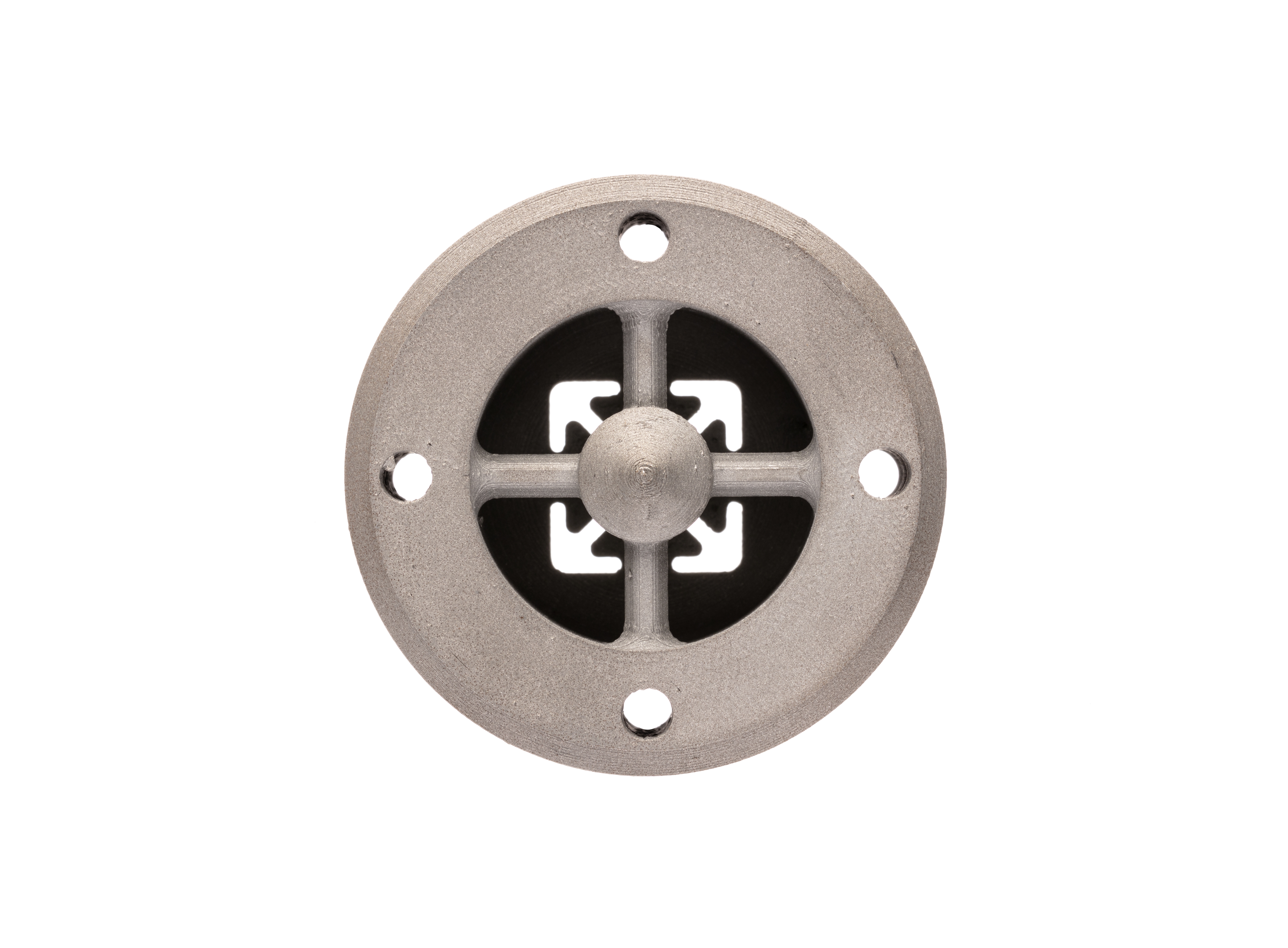

Mouthpiece injection mold core

About the part

Injection molding is the most common way to produce plastic components in high volume. To improve shop efficiency, as well as reduce tooling and labor costs, shops commonly use Master Unit Dies (MUD’s). These MUDs utilize swappable mold inserts to provide the core and cavity of the part being molded. These cores and cavities direct the injected molten plastic into the correct locations to form the part. Once the plastic has solidified the mold is cooled and the part is ejected. This printed core is used to mold the mouthpiece for an asthma inhaler.

Why Print?

H13’s high hardness and toughness make it extremely difficult to machine, resulting in long lead times, high part costs, and accelerated wear on end mills and drills. With metal 3DP, you can achieve the near net shape of your part quickly, requiring only a final secondary operation finishing pass via EDM or machining. During the injection molding process, cooling of the mold can account for up to 95% of the entire mold’s cycle time. By printing this mold the part was able to incorporate a conformal cooling channel that closely follows the molding surfaces profile. This conformal cooling channel greatly increases the cooling rate of the mold, dramatically reducing the mold’s cycle time, allowing more parts to be molded every hour.

Extrusion die

About the part

Hot extrusion works by heating a material to its recrystallization temperature and pushing it through a die with the desired cross section of the final part being extruded. When the desired part length is reached the extrusion is cut and the process continues. During the extrusion process the die must withstand the extreme temperatures and pressures required to successfully extrude the material through the die.

This die is used to extrude various lengths of framing material.

Why print?

The complex lofted geometry of an extrusion die makes it a difficult part to machine, especially when made of tool steel. This manufacturing challenge contributes to long lead times and high cost, limiting manufacturers’ ability to iterate on die designs. By printing extrusion dies, design teams are able to quickly and affordably produce different iterations of die designs. The reduced part cost also contributes to expanded opportunities for cost effective short runs that previously were not economical.

Zipper mold

About the part

Hundreds of millions of zippers are manufactured every year, with the primary manufacturing methods being injection molding (for plastic zippers), and die casting (for metal zippers). This mold is used to create custom metal zippers out of zinc via die casting.

Why print?

Due to the high cost of tooling, zippers are often produced in high volumes in order to achieve a low target cost per part. With metal 3D printing, manufacturers are able to cost effectively produce custom mold inserts to die cast zippers designed specifically for low volume applications, allowing for many different designs to be produced. This mold features many fine details, such as a logo, textures, and subtle draft angles that are critical for the part’s molding success. This part was printed with the Desktop Metal’s high resolution 250um nozzle to achieve the fine details that were required. By printing this part the manufacturers were about to save valuable time and cost compared to the machining and wire EDM work that would be required to produce this mold.