4140 Chromoly Steel

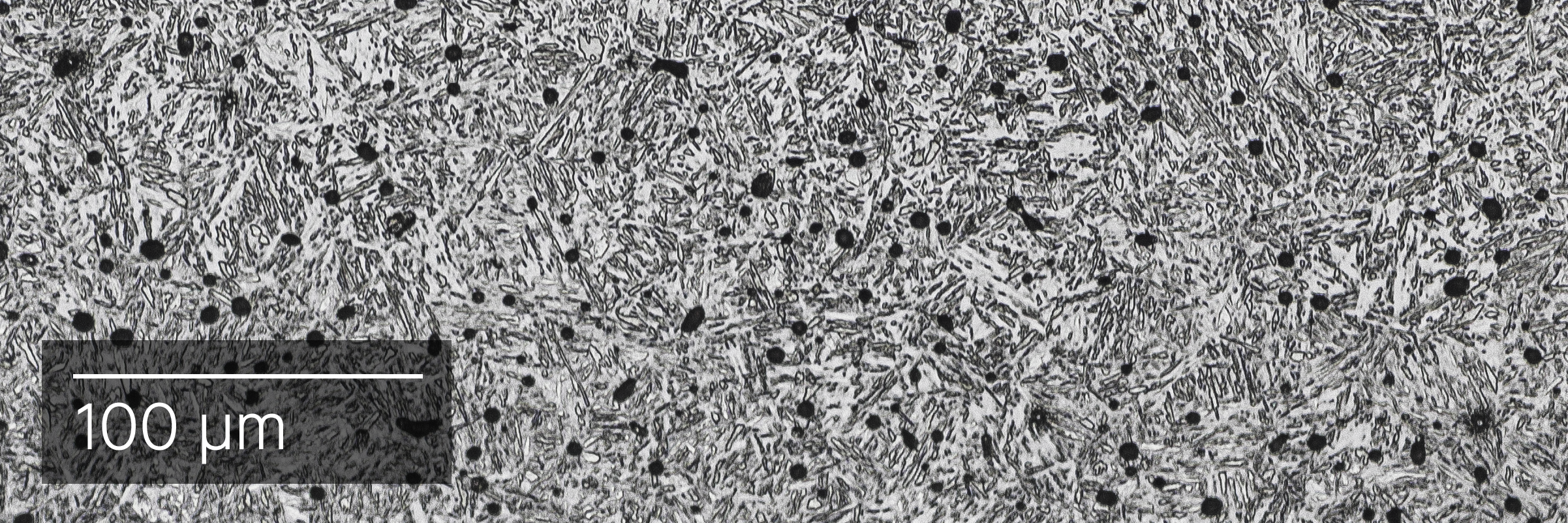

About 4140 Chromoly Steel

A versatile alloy with applications that include aerospace, tool and die manufacturing, the oil and gas industries, as well as automotive, agricultural and defense sectors, 4140 steel displays an excellent general tooling and end-use material due to its high strength-to-weight ratio, torsional strength and general toughness.

A low alloy steel that contains chromium, molybdemum, and manganese, 4140 is typically used to create gears, spindles, fixtures, jigs and many other parts, including:

- Couplings

- Connecting Rods

- Sheet Metal Tooling

- Pump Shafts

- Sprockets

BMD + 4140

Using the BMD process, users can quickly fabricate a wide variety of parts for testing against real-world conditions. Printing in 4140 using the Studio System can also allow shops to cost-effectively create custom tools for small and specialty jobs, while still keeping per-part costs low.

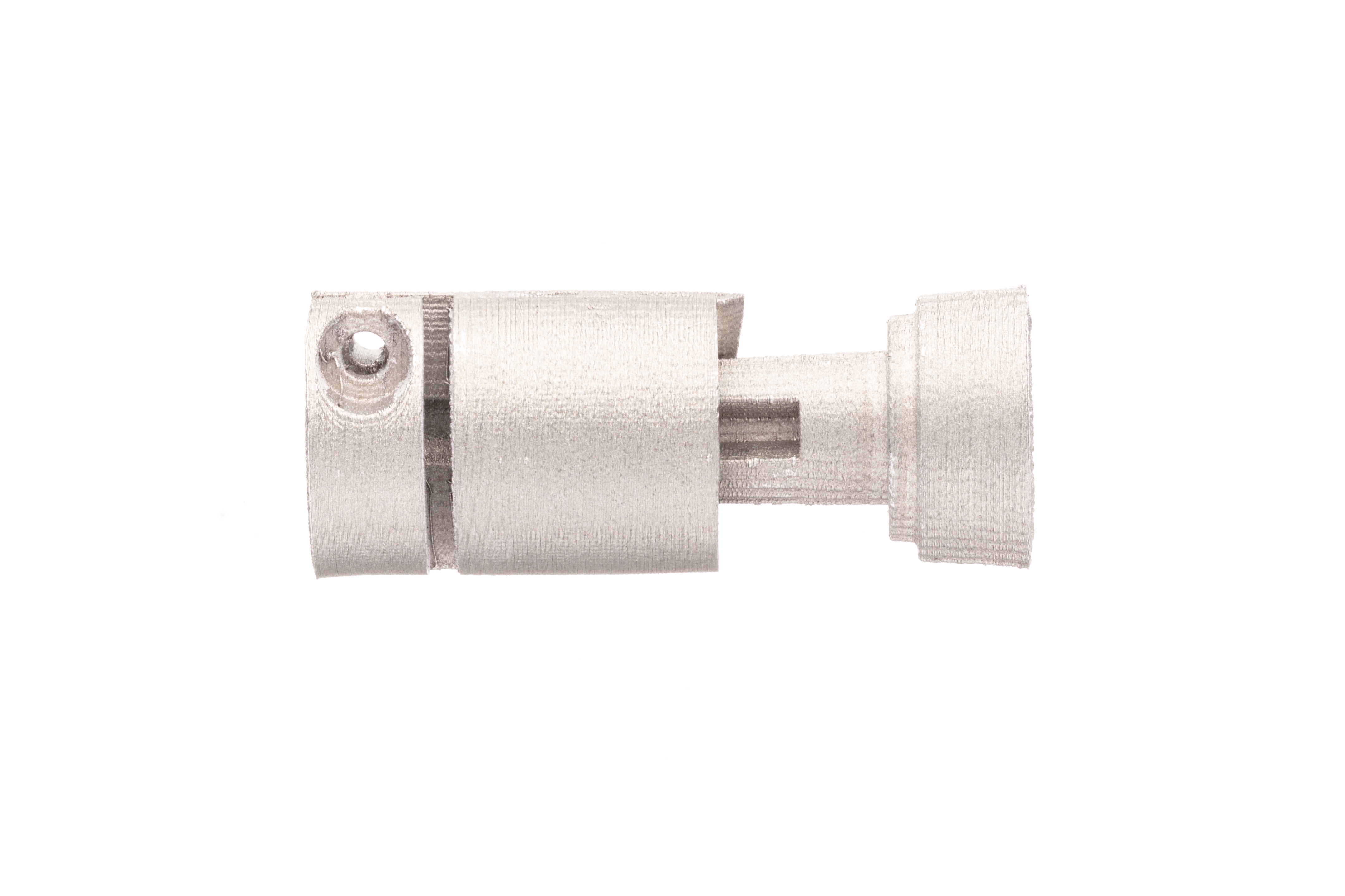

Mechanical Coupling

About the Part

A common component in many types of machinery, mechanical couplings are used to connect two rotating parts and are available in a wide variety of configurations. Where off-the-shelf parts don’t suffice, though, custom couplings must be fabricated for the specific application - a process that can be both time-consuming and expensive. This coupling is used to attach a motor in a hopper metering system.

Why Print?

The complex geometry and fine features of this coupling make it difficult and expensive to machine. Using the Studio System, the design team can produce a prototype in a matter of days, then test its functionality in the machinery where it would be used. Printing this part allows engineers to create working models of machinery faster and with less expense.

Connecting Rod

About the Part

A key component in combustion engines, the aptly-named connecting rod is used to connect the piston head to the crankshaft. During combustion, connecting rods experience significant loads and must endure high temperatures, so functional testing must be conducted using metal parts. This connecting rod shows one iteration in the design of the part for combustion engines.

Why Print?

The ability to create functional prototype parts in a matter of days, and then rapidly iterate on those designs ensures engineers can develop the most efficient components and validate how they perform before committing to the manufacture of potentially millions of parts via casting or forging.

Press brake tooling

About the Part

Press brake tools are used to create predetermined bends in sheet metal, and have a wide range of applications ranging from the production of heavy-duty metal parts, to electronics enclosures to construction, to name just a few. This tool is used to create a custom bend angle in aluminum.

Why Print?

The long lead times and increased costs that accompany custom tooling make it impractical for smaller or specialty jobs. Printing allows shops to quickly create custom tools and take on specialty jobs while still keeping per-part costs low.