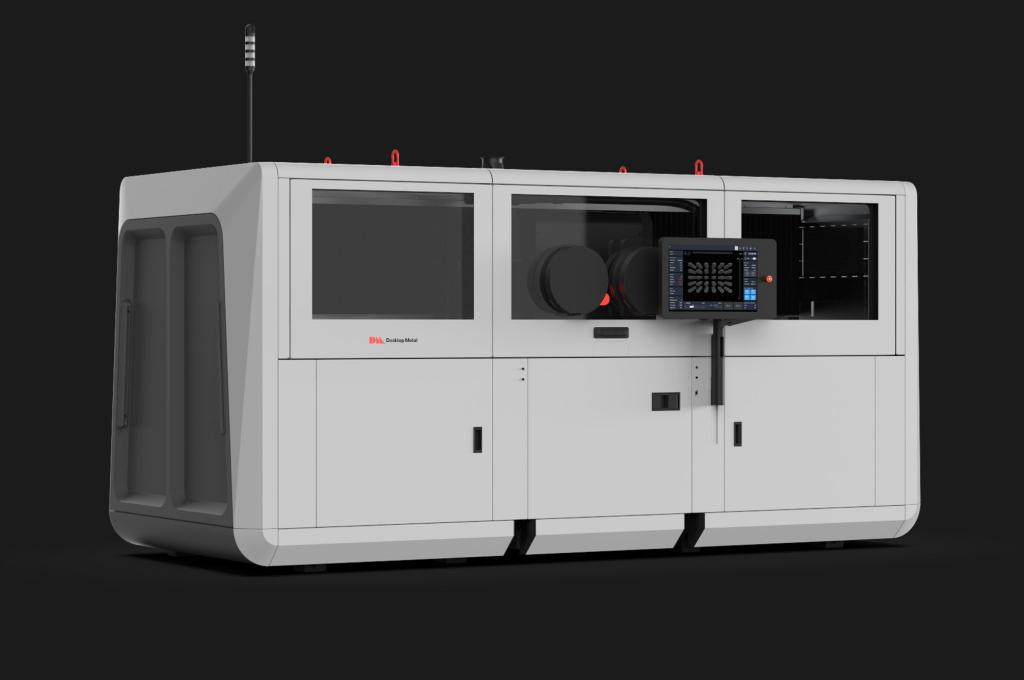

Production System™

High-speed metal 3D printing for mass production

-

— 01

Excellent part quality

-

— 02

Competitive cost per part

-

— 03

Best in class repeatability

-

— 04

Wide material compatibility

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System™ is designed to be the fastest way to 3D print metal parts at scale.¹

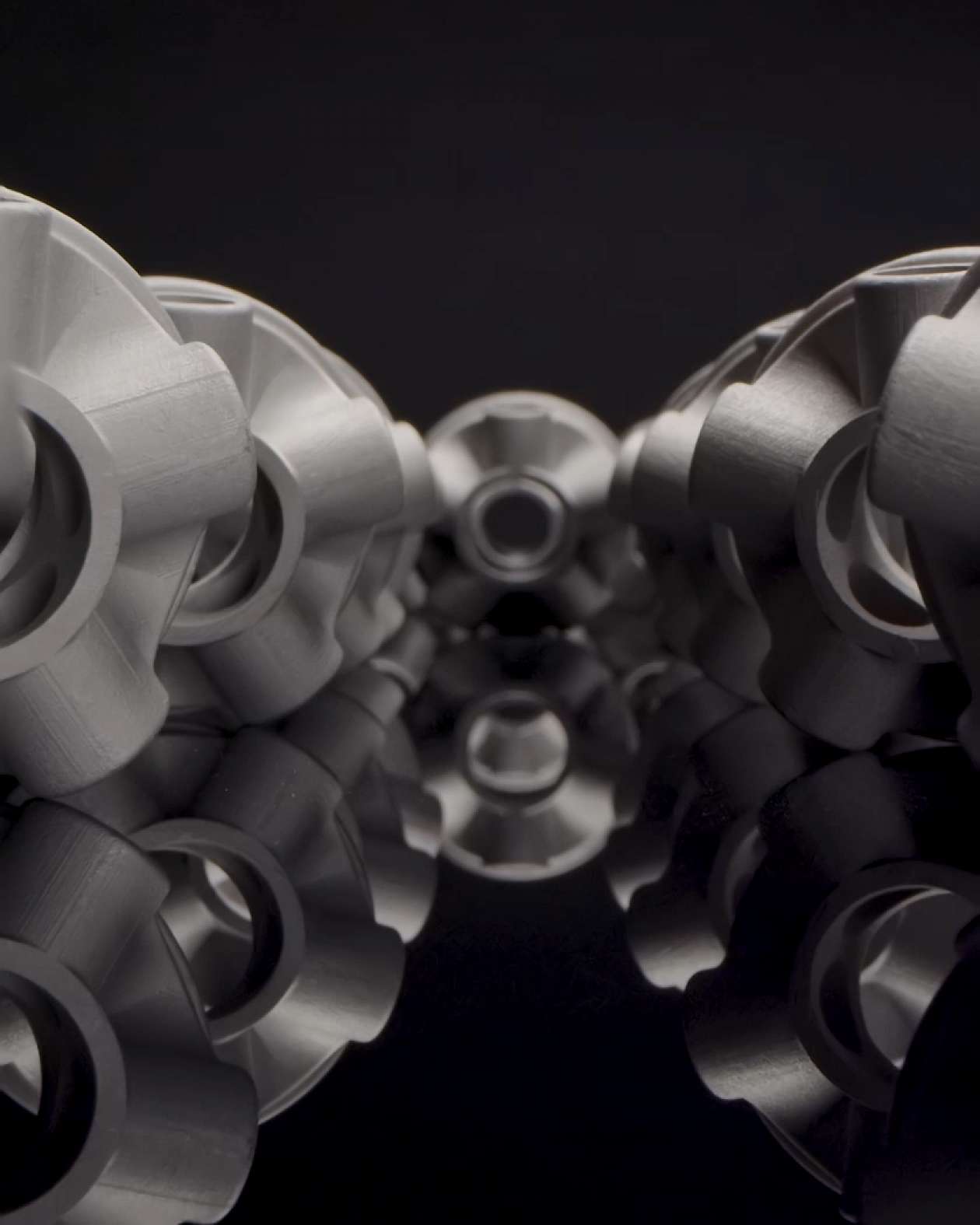

Excellent part quality

High-resolution 3D printing and a uniform print bed allow the Production System™ to produce dense, high-quality parts capable of performing in the most demanding applications.

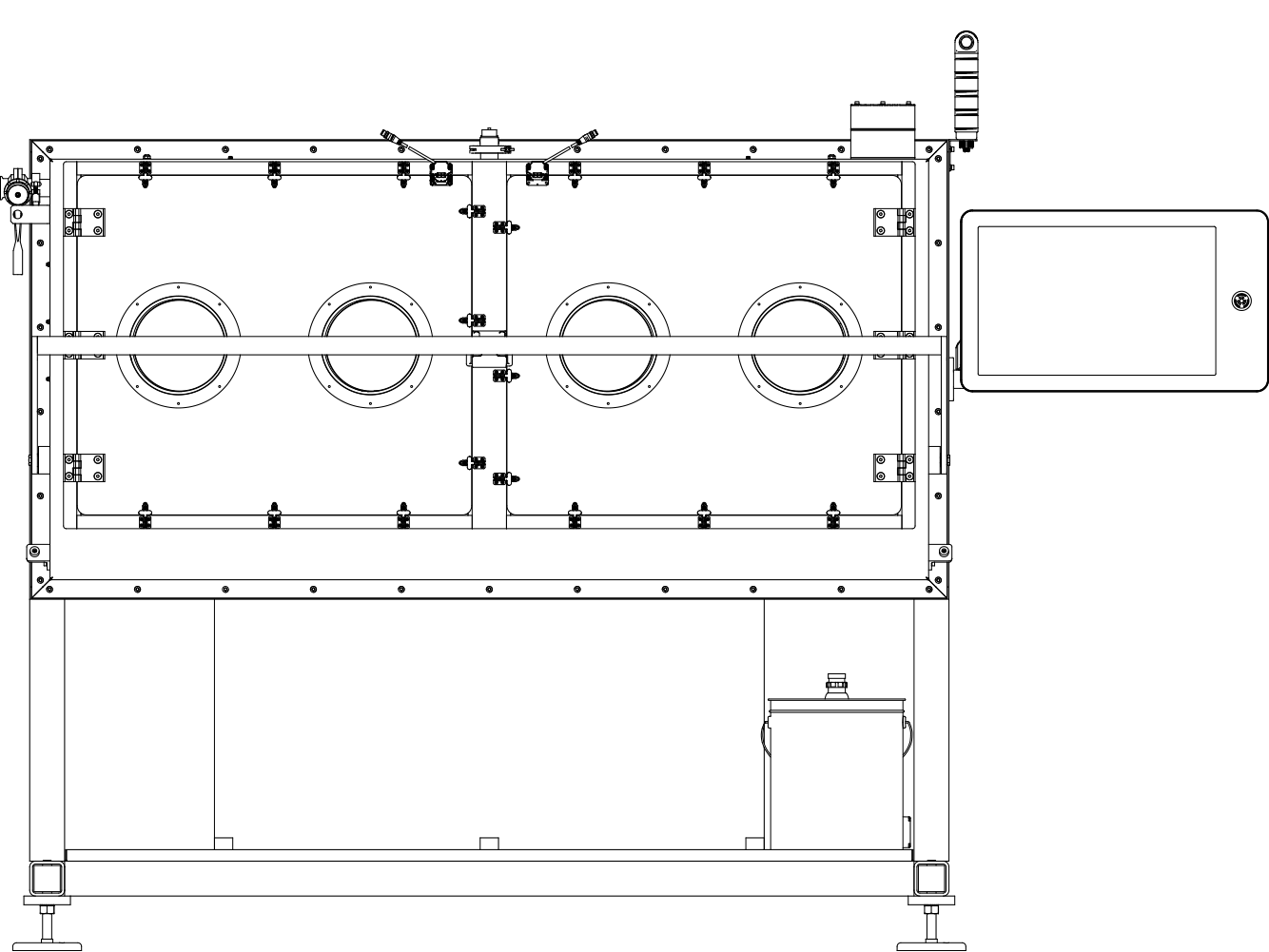

Uniform print bed

Proprietary constant wave spreading technology maintains a consistent powder wave in front of the compaction roller during printing, enhancing density uniformity across the powder bed. The result is greater consistency across parts within each build and from build-to-build.

Fully dense parts

3D print customer-ready parts with densities up to or exceeding 99% without the need for infill or a solvent debind step. With properties similar to castings, Production System™ parts are suitable for demanding applications where strength is critical.

Competitive cost per part

Delivers part cost competitive with traditional mass production techniques through the use of low-cost metal injection molding (MIM) powders, high-speed 3D printing and the ability to densely nest many parts in a single build.

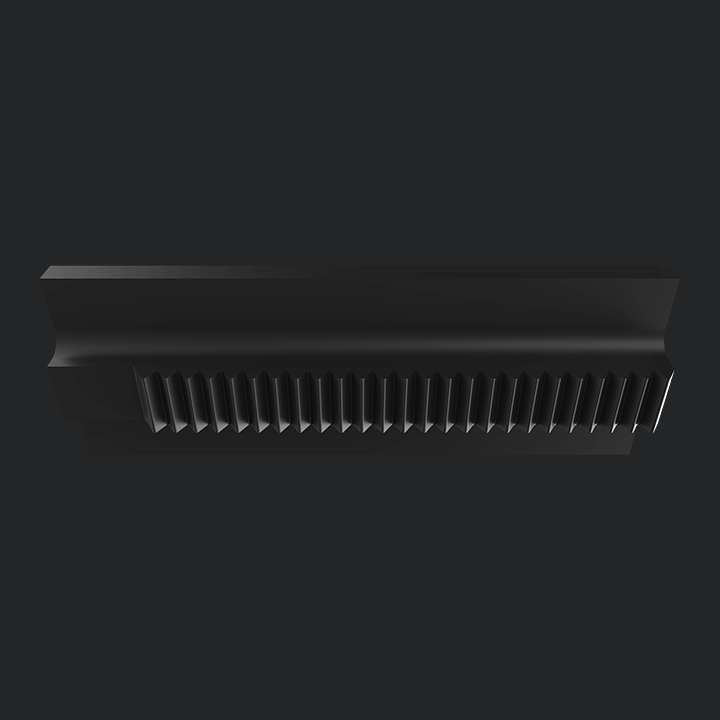

High speed printing

Up to tens of thousands of parts per day³ can be 3D printed with the Production System’s™ bi-directional, Single Pass Jetting™ (SPJ) print technology, which utilizes each pass of the print carriage to build parts, achieving print speeds of up to 100x those of laser powder bed fusion systems, maximizing productivity.⁴

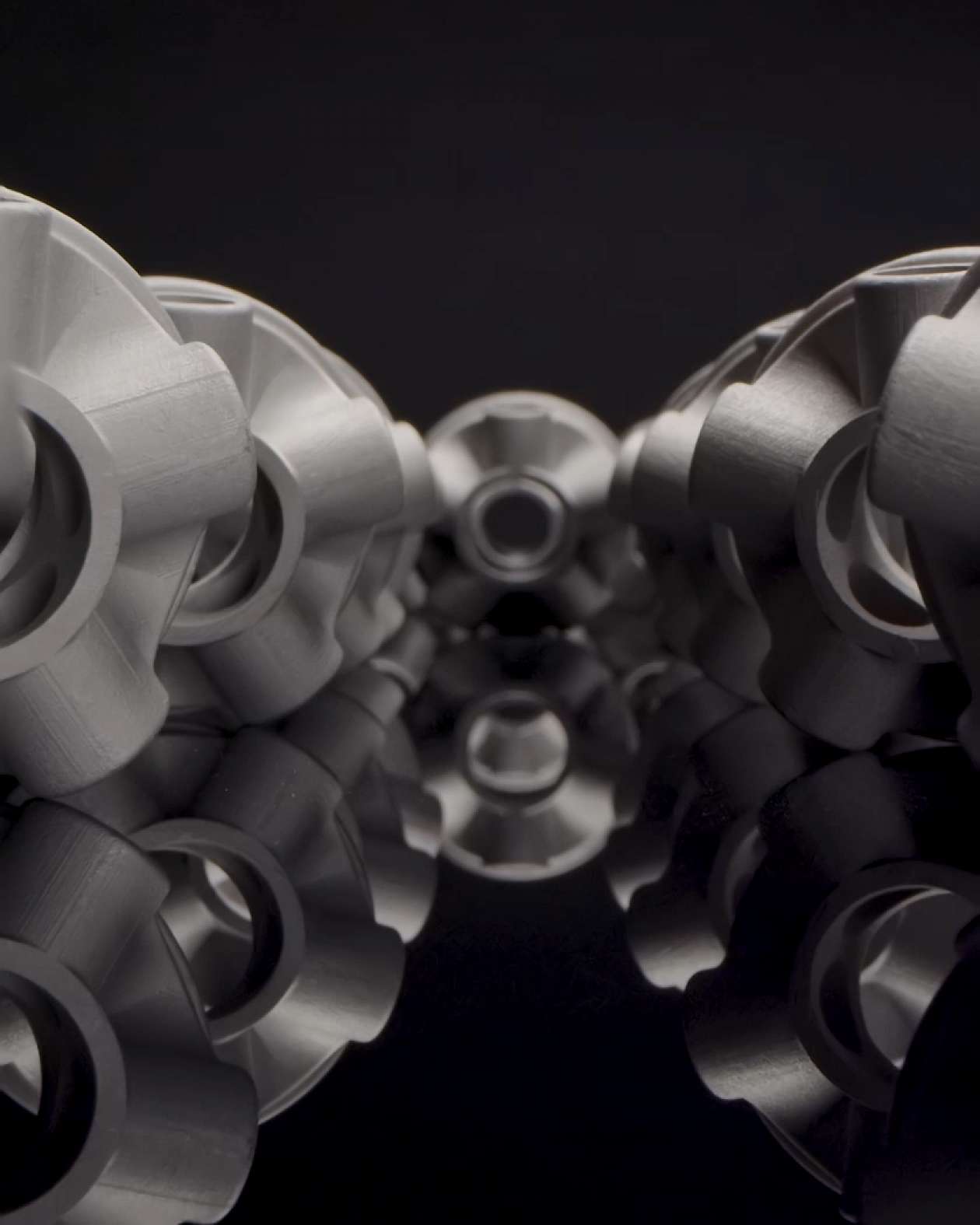

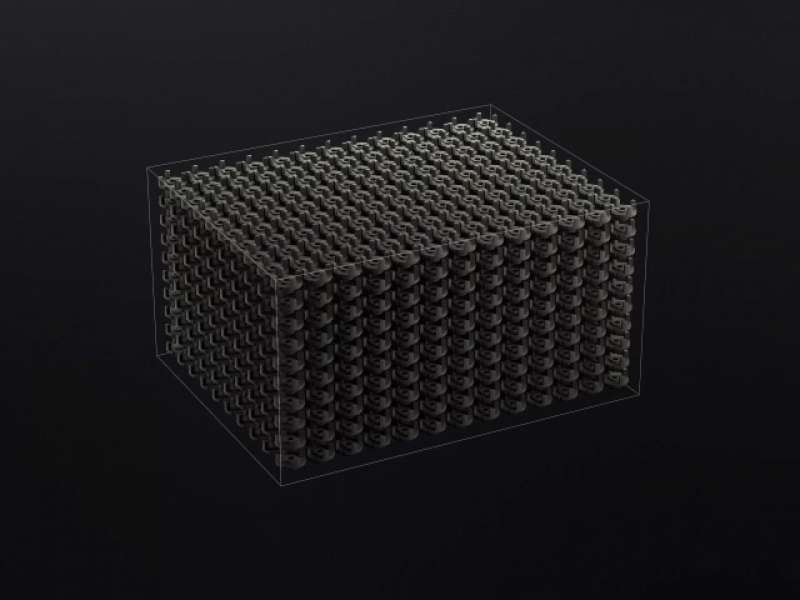

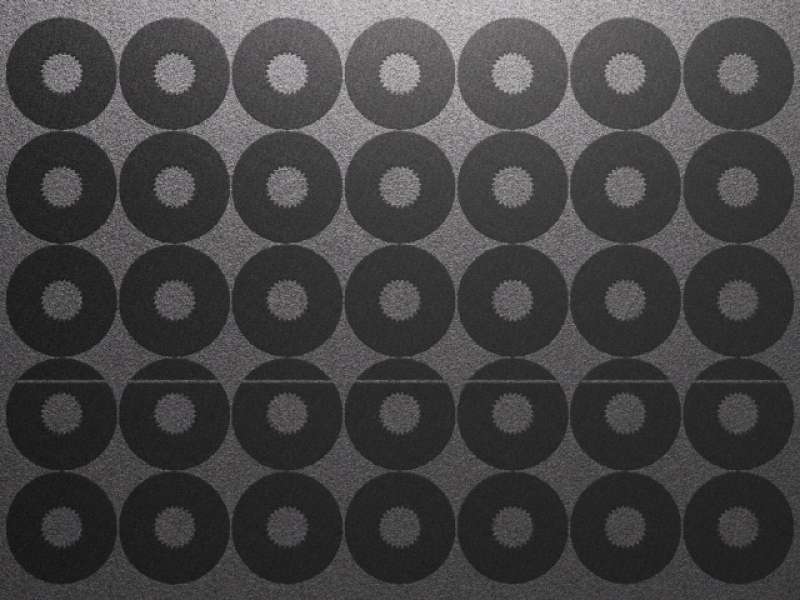

Dense 3D nesting

The tooling-free, binder jetting 3D printing process of the Production System™ means parts are supported by loose powder and do not require welding to a build plate. This enables customers to fill the build volume with densely nested parts to efficiently deliver high-throughput builds.

Best in class repeatability

The Production System™ offers robust repeatability, through anti-ballistics technology, print bar redundancy and live optical print bed inspection. Meaning you can print with confidence.

Print bar redundancy

Full print bar redundancy is achieved using an anti-banding mechanism in which the print bar is re-aligned between layers, ensuring reliable binder deposition and suppressing defects that would otherwise affect final part quality. This mechanism eliminates the need for hard, nozzle-based redundancy while improving maintenance accessibility.

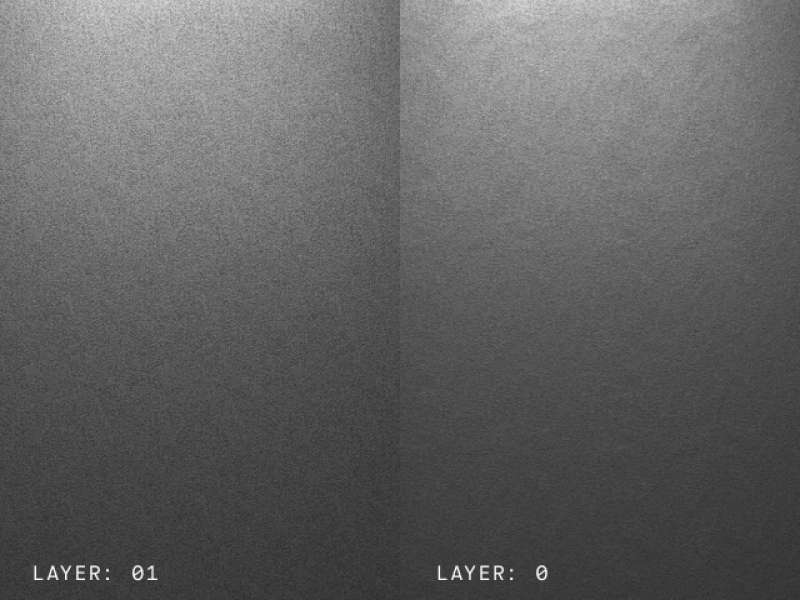

Real-time print bed inspection

An overhead camera monitors each layer using multi-angle imaging to detect print defects and nozzle performance during printing, facilitating part inspection and build audits critical to deploying additive manufacturing in production environments.

Wide material compatibility

The Production System's™ inert environment, open material platform, and selection of Desktop Metal-engineered binders enable 3D printing with a wide variety of metals—including everything from stainless steels to reactive metals and high-performance alloys.

Open material platform

The Production System™ features an open material platform which allows customers to source the same metal powders used in the MIM industry or custom alloys from their supplier of choice, keeping costs low and ensuring compatibility with bulk sintering processes.

Desktop Metal-engineered binders

Developed by expert materials scientists at Desktop Metal, our proprietary binders are formulated to support a broad array of alloys and to maximize success through every stage of the binder jetting process - ensuring jettability during printing, green part strength during depowdering, and clean burn off prior to sintering.

How it works

Powered by Single Pass Jetting™, the Production System™ features bi-directional 3D printing—so whenever there is movement, there is printing.

-

Print

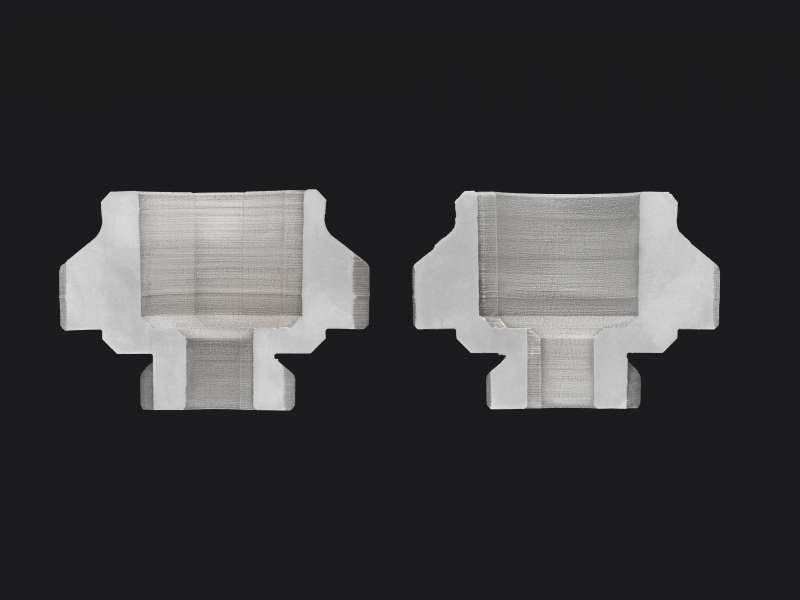

With bi-directional single pass jetting, all steps of the print process—powder deposition, spreading, compacting, ballistic suppression, and binder jetting—are applied with each pass over the build area. Layer by layer, metal powder and binder is deposited until the entire build volume is packed with bound parts and surrounding loose powder.

-

Depowder

When a build is complete, the build box is removed and replaced with a fresh box for the next build. The completed build box is moved to a depowdering station where loose powder is removed and parts are prepared for sintering.

-

Sinter

Depowdered parts and loaded into an industrial furnace where they are heated to temperatures near melting. Remaining binder is removed causing the metal particles to fuse together and the parts to densify.

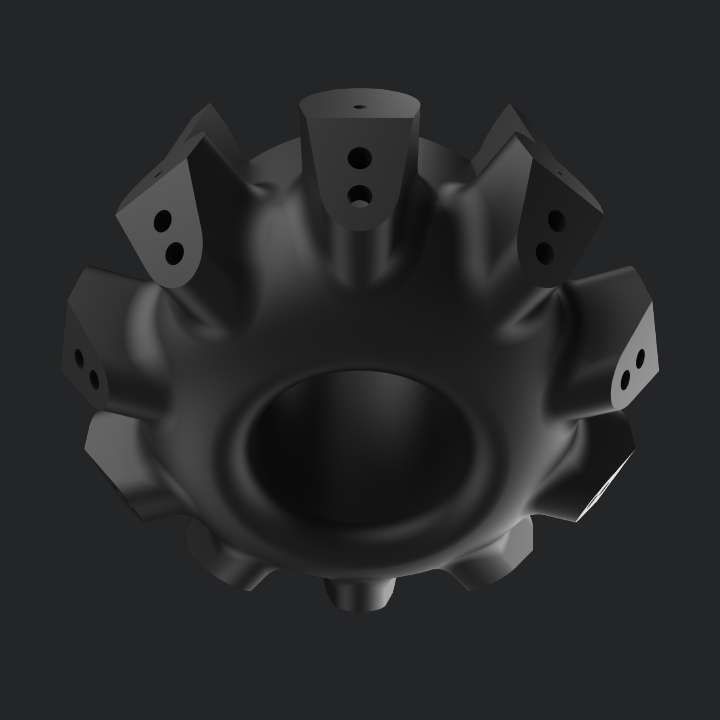

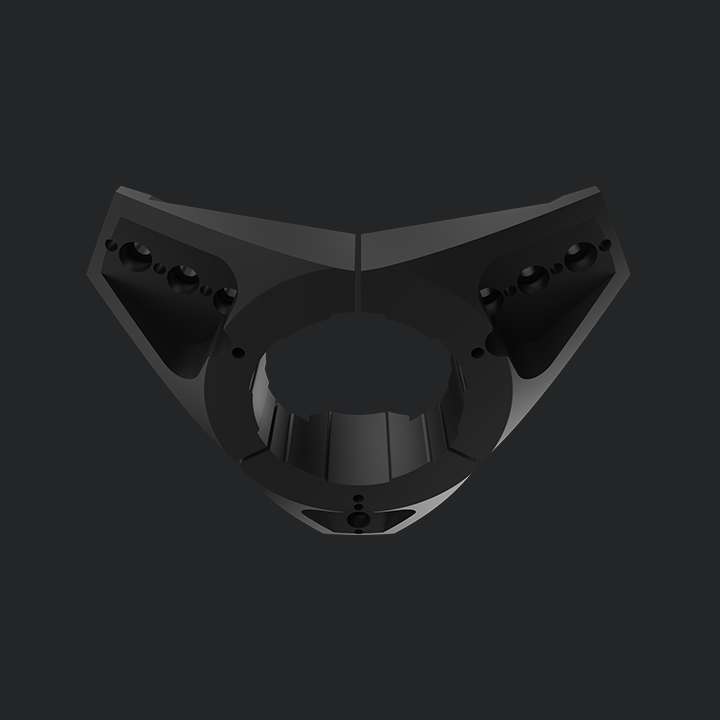

Part Gallery

The Production System™ delivers the speed, quality and cost-per-part needed for metal 3D printing to compete with traditional manufacturing.

Applications by industry

Explore applications for 3D printing across a range of industries.